HYPERFORE

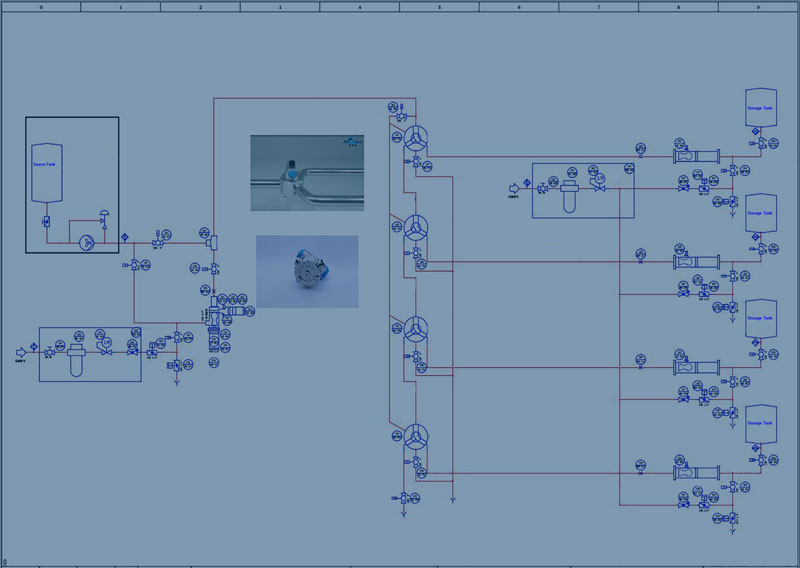

Pigging Process Engineering & Turnkey Solutions

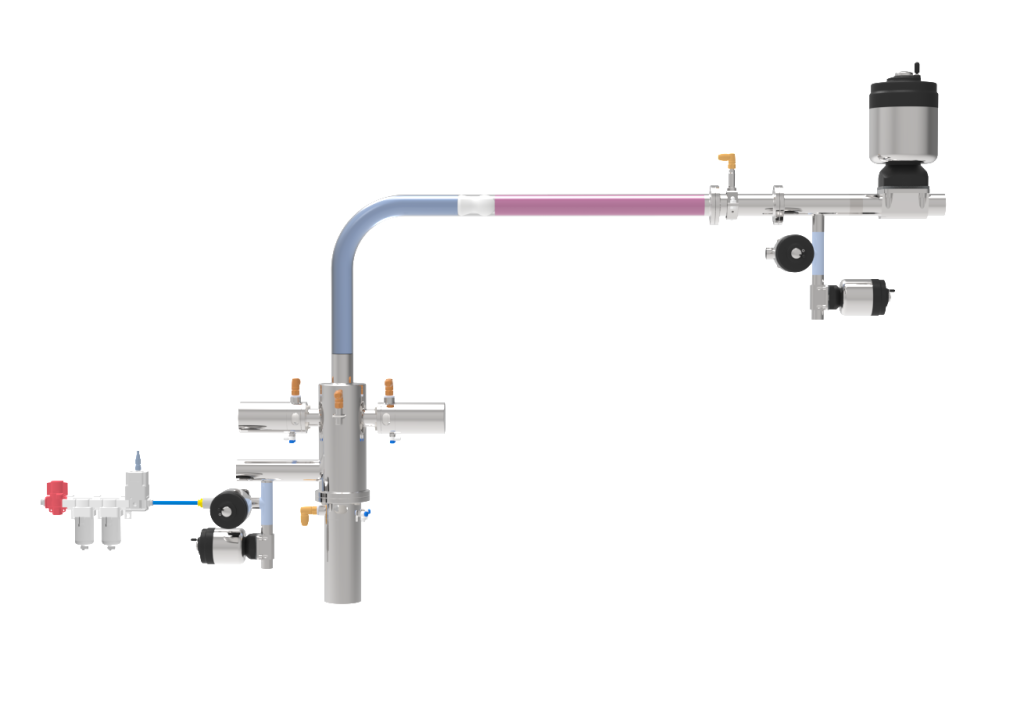

From precise requirements analysis and custom process design to on-site installation and remote guidance, Hyperfore provides tailored turnkey pipeline pigging process solutions for food, pharmaceutical, paints and industrial liquid transferring pipelines,ensuring maximum product recovery and minimal residue.

Requirements Analysis

A precise pigging process design starts with the deep understanding of the customer’s requirements and challenges. This step is the foundation of successful pipeline pigging process engineering. Our engineers conduct a comprehensive investigation of your production status, including product characteristics, pipeline parameters, equipment layout, production frequency, production capacity and ROI target. We raise our proposals and the optimiz ation advice, including the pipeline modification, automation upgrade and deliver a final solution that aligns with your operational goals.

Custom Pigging Process Design

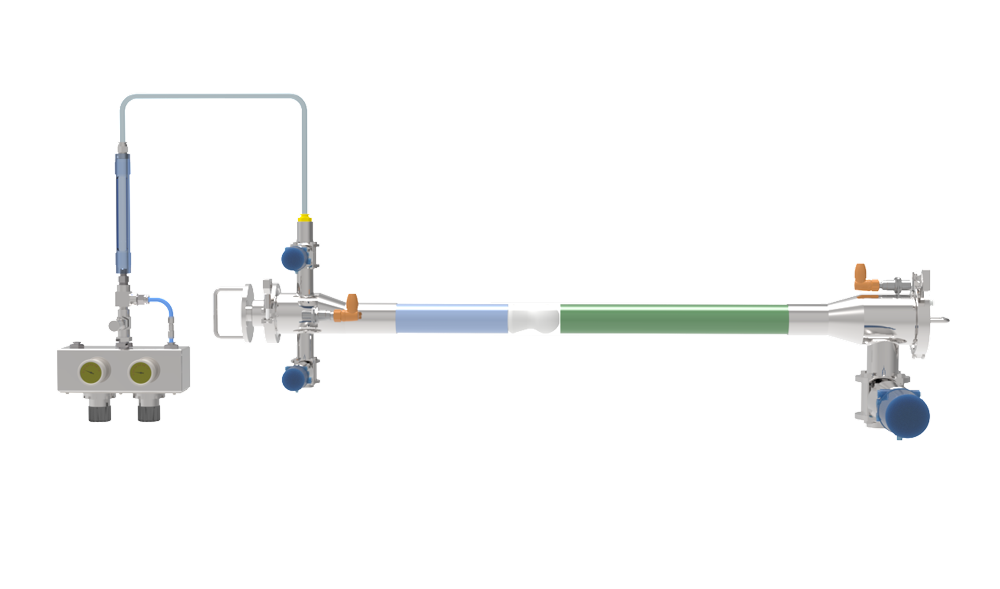

We offer multiple pigging system configurations,fully customizable to match your specific targets.| Solution | Typical Application | Key Benefits |

|---|---|---|

| Single-source to single-destination | Simple point to point transfer | Low investment, easy maintenance |

| Single-source to multi-destination | One tank to multiple tanks, or fillers | Flexible, lower equipment investment cost |

| Multi-source to single-destination | Multiple tanks to one tank or filler | Flexible, efficient, shorter changeover downtime |

| Multi-source to multi-destination | Multiple products batch transfer | Flexible, efficient, longer uptime |

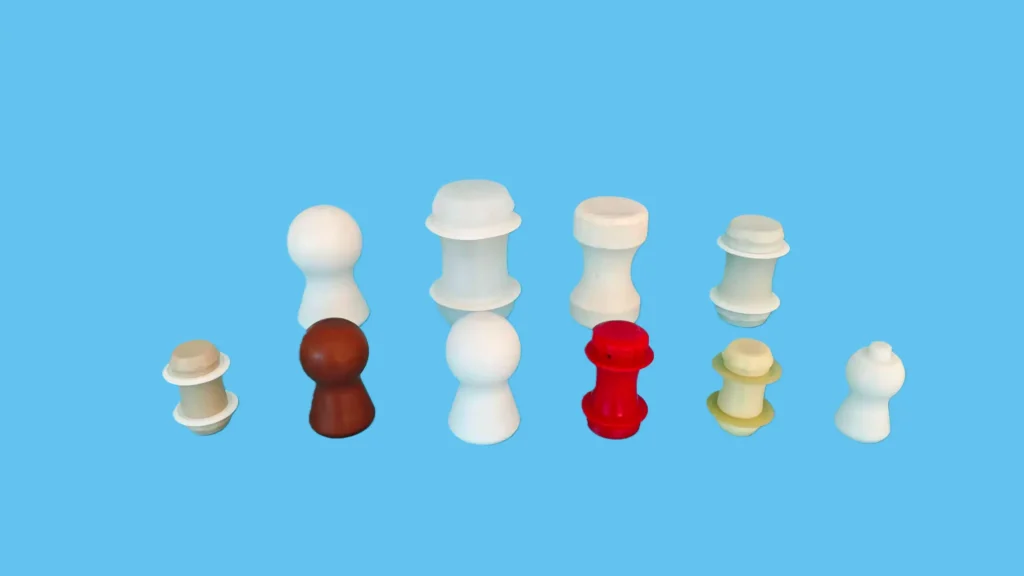

| Dual-pig system | Paints and coatings, oxygen sensitive and high purity products | Physical isolation from air |

| Micro-residue pigging system | Paints and coatings, chemicals and high purity products | Zero residue, eliminate cross-contamination |

| Low-residue pigging system | Paints and coatings, chemicals, short pipelines | Minimize cross-contamination, maintaining product integrity |

| Matrix manifold pigging system | Complicated pipeline transfer | Minimizing pipeline investment, high efficiency |

On-Site Installation

Hyperfore delivers professional on-site installation service with precision and expertise. We ensure all launchers, receivers, elbows, and valves are installed precisely according to the P&ID. With rich engineering management experience, we carefully monitor the installation, commissioning and testing phases to guarantee the consistent pig movement and the system’s seamless integration into your existing infrastructure. We provide detailed commissioning report and training to ensure smooth operation in the long run.

Remote Technical Support

Hyperfore provides detailed remote technical instruction to guarantee that your system’s smooth operation, ensuring seamless support regardless of geographical distance.

Remote Installation Guidance: Real-time video or telephone to guide your local team to solve the problems based on our guidelines. Remote Commissioning: Our team can assist with system commissioning and testing via secure remote internet access. Operator Training: We offer remote training service to guide the local team step by step online, ensuring they fully master the system operation. Troubleshooting: In case of any emergency, we provide fast feedback to minimize downtime.

FAQ

Contact Us

Have questions about pipeline pigging process or pigging system design? Use the form to reach out and we will be in touch with you as quickly as possible.