Case Study-Pigging System To Recover Lithium Battery Slurry

SANY Used Pigging System To Recover Lithium Battery Slurry

Case Study- SANY

The pigging system (product recovery system) implemented by Hyperfore has led to a significant increase in profitability for China SANY in the production of lithium battery slurry. This improvement is primarily due to the system’s ability to enhance yield, reduce waste, increase efficiency, and promote environmental protection.

Summary

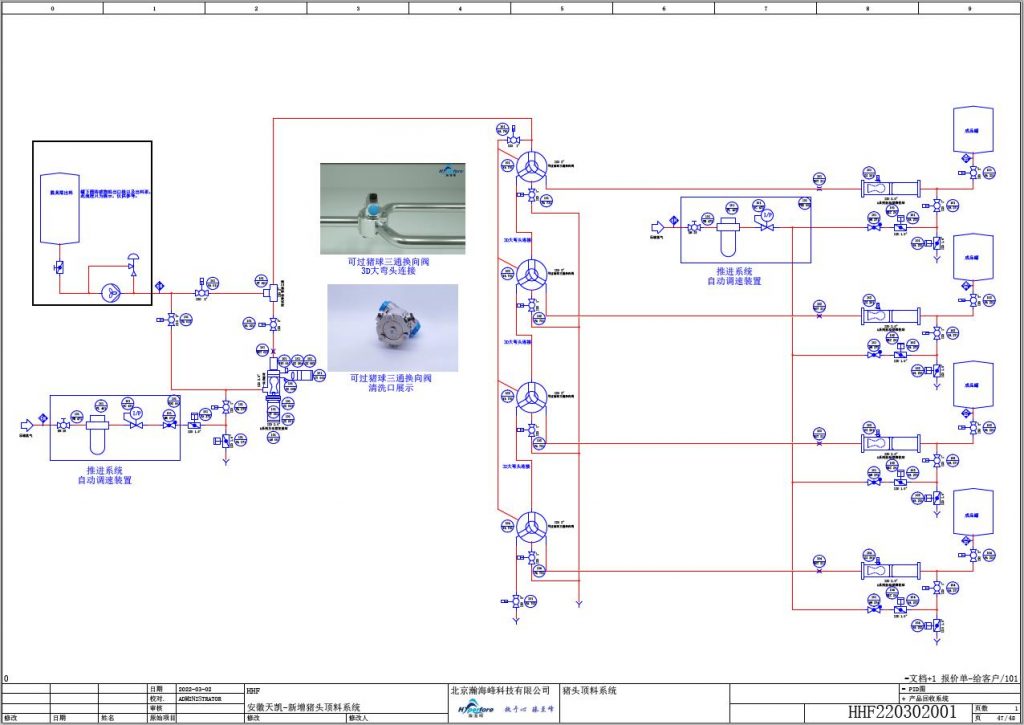

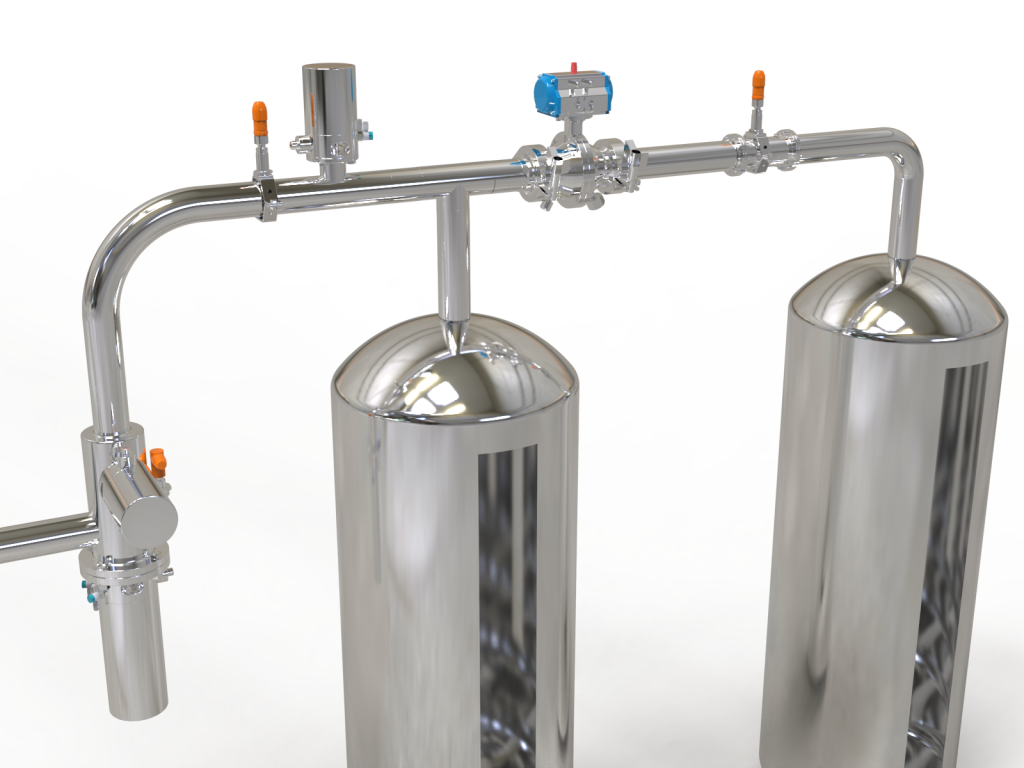

Hyperfore has installed two sets of automatic pigging systems specifically designed for the lithium battery industry in two coating machines in SANY’s workshop. These two coating machines are identical in appearance and located on opposite sides of the workshop. The mixed solution of powder and water, known as slurry, is stored in a large mixing tank. At the outlet of the mixing tank, there is a rotor pump that pumps the slurry to the pipelines and then to the two small storage tanks at the head and tail ends of the coating machines. Our automatic pigging system is installed between the head and tail ends of the machine, collecting residual slurry from the pipelines and returning it to the storage tank at the head end. This allows the slurry in these two storage tanks to be used as aluminum-based coating for the coating machine. After installation, our pigging system has been working well, reducing waste of lithium battery slurry, improving production efficiency, and achieving customer goals.

Project Introduction

Sany Group is a leading manufacturer of lithium battery slurry, and they have a branch that specializes in this product. The slurry needs to be transferred from the tail end to the head end of the coating machine, which are two different positions in their plant. However, after the transfer, a lot of slurry remains in the pipeline, and it cannot be delivered to the storage tank due to its sticky nature. As a result, it has to be washed away as waste. To address this issue, Sany Group is looking for a way to recover the left slurry. Our customer, who has never used a pigging system before, is worried about the pigging system price. Meanwhile ,they don’t know how to choose pigging system. They have two pipelines that need to be recovered, the slurry viscosity of around 8000CPS, and the pipeline length of 100m, and a diameter of DN65. We assure them that our pigging system can handle this viscosity without any issues. They also express concerns about the reduced cross-sectional area of the pig due to its placement in the launching station. However, we explain that the bi-directional pig only occupies a quarter of the cross-sectional area, so this should not be an issue. Since the lithium ion battery slurry is conveyed along the main pipeline, the destination tank is on the bypass line. Based on this information, we recommend our automatic pig stopper and piggable ball valve to our customer. One of the major functions of the pig stopper is to block the pig from moving while allowing the slurry to pass through. By combining the piggable ball valve, the product can be delivered to the designated storage tank. This system provides an efficient and cost-effective solution for recovering lithium battery slurry without wasting valuable product.

Hyperfore Supplied Tailored Pigging Solution For Lithium Ion Battery Slurry Recovery.

Hyperfore has successfully completed the turnkey project for Sany Group, which includes the pigging process design, pigging automation system, electrical control panel, installation and commissioning, and technical support. Our team is experienced in the field and can provide customers with high-quality solutions.Our pigging system uses Siemens S7-1500 and HMI as the control platform, and our software is integrated into the customer’s system to ensure easy operation and flexibility. The system has been designed to meet the specific needs of Sany Group, and we have implemented it according to their requirements.During the installation process, our team worked closely with Sany Group to ensure that the system was installed correctly and efficiently. We paid special attention to issues such as pipeline layout and support, piggable elbow selection, tee fittings, clamp and flange selection, welding methods and requirements to ensure that the pigging system could operate safely and smoothly.The material used for the pigs is specially designed to be compatible with lithium battery slurry, ensuring a smooth and safe transfer of product from the tail end to the head end of the coating machine. The pigs are also easy to operate and require low maintenance costs, making them a cost-effective investment.In addition to providing excellent installation services, we also offer remote technical support through the internet. If our customers encounter any problems during use, we can quickly resolve them and provide timely solutions to ensure that production is not affected.Overall, our turnkey project has greatly improved Sany Group’s productivity by reducing waste and increasing efficiency. We are committed to providing high-quality solutions and excellent customer service to meet our clients’ needs.

The Project Result

The pigging system has been successfully put into use and is running very well. The plant now runs the pigging system twice a day, which means that the frequency of lithium ion battery slurry recovery is about 60 times a month. By using our pigging systems, they are able to save 1.6 tons of product every day, which amounts to approximately 8000 yuan per day and 240,000 yuan per month. This translates to a significant return on investment for our customer in just a few months.Whenever the plant encounters operating problems, they turn to us for remote technical support. Our patient and professional guidance always makes them feel very pleased and satisfied. The customer also believes that our pigging system and the turnkey project have updated their production process and raised efficiency significantly.One of the key advantages of our pigging system is its ability to recover valuable product that would otherwise be wasted. By recovering around 8000 yuan per day, the customer is able to generate significant cost savings over time. In addition, the use of our pigging system has improved the efficiency of their production process, allowing them to achieve higher output levels with less waste and lower costs. Our team takes pride in providing excellent customer service and support. We understand that any operational issues can have a significant impact on a business, which is why we are committed to providing timely and effective solutions to ensure that our customers can continue to operate at maximum efficiency. We are confident that our pigging system and turnkey project will continue to provide value to Sany Group for many years to come.

LEARN MORE

Are you considering to install customized pigging systems on your productions lines, do you want to know more about the pigging system cases, like paints and coatings, please cantact us.

What Benefits Customer Can Get From Hyperfore Pigging services?

Equipment

Our pigging system is high quality product, and very effective.

Automation

Our automation system is powerful, it speed up the production operation.

Remote service

Our remote service responds quickly, fix customer’s problems any time.

Save product

The most direct benefit for the customer is to save tons of product per month.

Improve profit

Our pigging system save product,and thus improve customer’s profit.

Responsible partner

Hyperfore is responsible and reliable, we supply considerate after-sales service.

Related Products

Any questions, doubts, problems concerning hygienic pigging system, manual pigging system, aseptic pigging system, or pigging products, just contact us!

Related Cases

Hyperfore have many pigging system cases, pigging solutions cases, such as pigging system for mayonnaise recovery, pigging system for lithium battery slurry, pigging system for pharmaceuticals, and so on.

Contact Us

Are you interested in pigging system case? Or pigging system return on investment? Use the form to reach out and we will be in touch with you as quickly as possible.