Case Study-Pigging System To Recover Liquid Chinese Medicine

REALCAN Used Pigging System To Recover Liquid Chinese Medicine

Case Study- REALCAN Pharmaceutical Co.

How the Hyperfore sanitary pigging system (product recovery system) help Chinese pharmaceutical manufacturers reduce product waste, improve efficiency, avoid pollution risk, and meet production requirements in the pharmaceutical industry.

Summary

REALCAN is a Chinese pharmaceutical manufacturer that produces Chinese liquid medicine and other kinds of medicines. Hyperfore provided 19 sets of automatic sanitary pigging system equipment, automation system installation and commissioning, as well as technical support services for REALCAN.

Hyperfore’s partnership with REALCAN for their Chinese medicine lines was a wise decision that paid off in the end. Our turnkey project provided them with a robust and reliable solution that helped them improve their operations and achieve their business goals more effectively.

Our team worked closely with REALCAN to understand their specific needs and requirements, and we were able to design a custom solution and pigging service that met their exact specifications. We provided comprehensive training and support to ensure a smooth transition and minimize downtime. Our solution included state-of-the-art technology and equipment that helped REALCAN increase production efficiency and reduce waste.

Thanks to our collaboration, REALCAN was able to increase their production capacity, improve quality control, and reduce costs. They were also able to respond quickly to market demands and adapt to changing conditions. Overall, our partnership with REALCAN has been a mutually beneficial one, and we look forward to continuing our work together in the future.

About REALCAN Pharmaceutical Co.

REALCAN Pharmaceutical Group was established on September 21, 2004, with a registered capital of 1.5 billion yuan and over 100 subsidiaries. The company has more than 9,000 employees and listed in Shenzhen A-share market on June 3, 2011. Its sales network covers all 31 provinces and municipalities in China, directly serving nearly 60,000 medical institutions. The company operates in almost all leading enterprises in the pharmaceutical industry in China. In recent years, the group has focused on building its eight major business segments: pharmaceutical distribution, academic services, medical diagnosis, financial technology, traditional Chinese medicine, digital healthcare, specialized logistics, and comprehensive medical equipment. It adopts an integrated management model of “one command center and ten unified management” and has established business relationships with nearly 30,000 pharmaceutical and medical device manufacturers at home and abroad, making it an important partner for major multinational pharmaceutical companies in China.

Pigging System Project background

REALCAN never used pigging system before, they don’t know ” what is pipeline pigging ” . We gave them detailed explanation about the the pigging system work principle. One of REALCAN‘s plants was processing traditional Chinese medicine, utilizing a dozen production lines that produced a large amount of output every day. However, the plant was struggling with significant waste due to their previous lack of pigging systems. One day, they reached out to us expressing their frustration with the waste generated during the filling process and expressed their eagerness to find an effective way to reduce it. Our engineer visited the site to gain a thorough understanding of their production process. After undergoing filtration and sterilization, the Chinese herbal soup was transferred to a storage tank where it awaited filling. The plant sought our assistance in pigging 19 pipelines from the storage tank to the filling machine. We are confident that our innovative pigging solutions will help this REACAN plant minimize waste and improve efficiency.

Hyperfore’s product recovery solutions

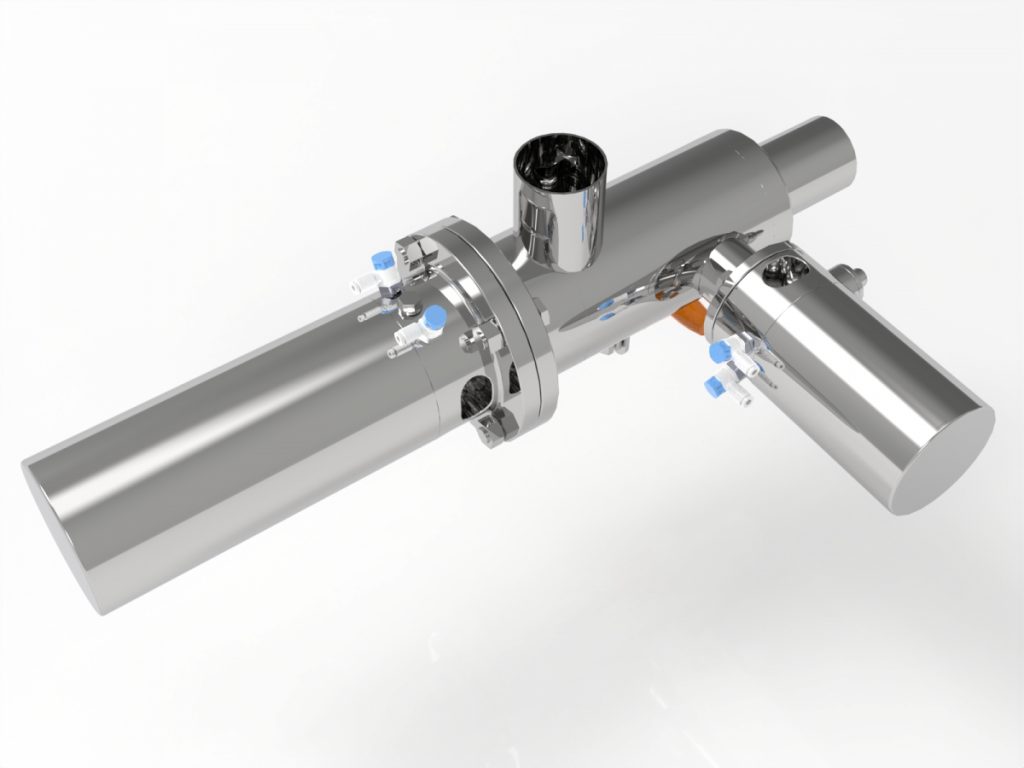

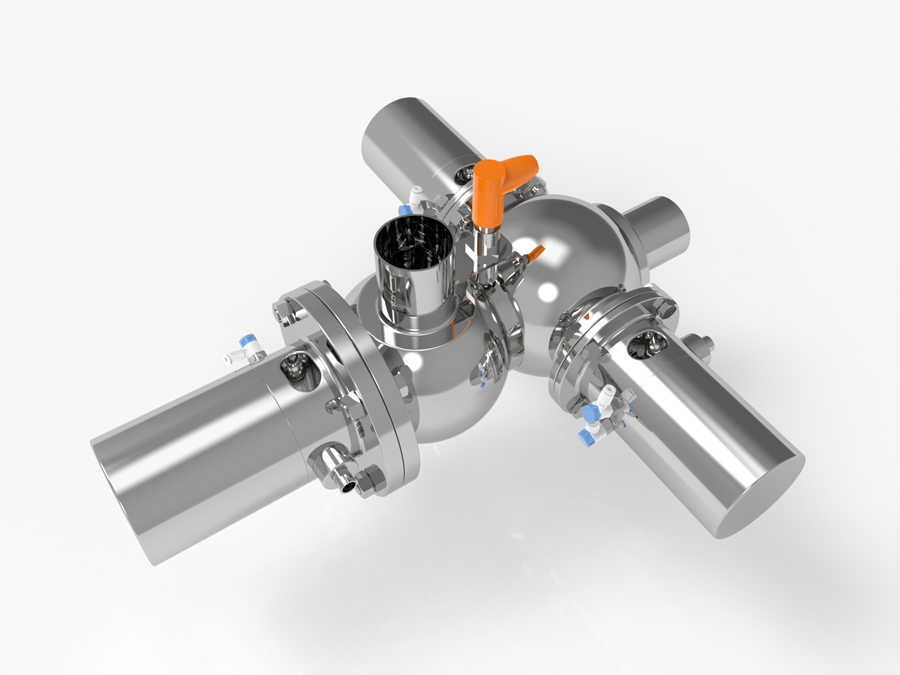

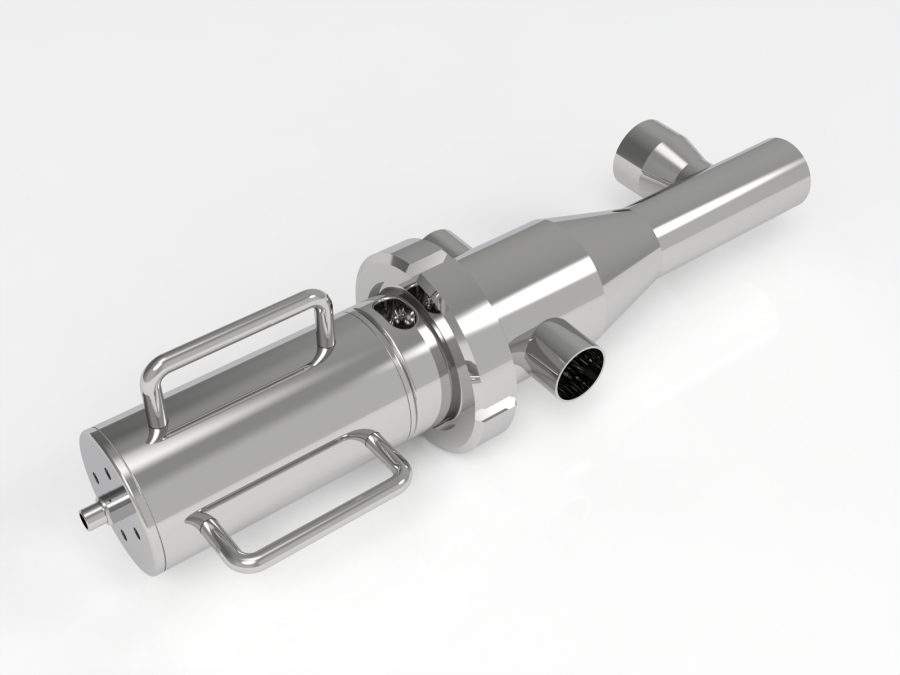

REALCAN plant was facing significant waste issues with their traditional Chinese medicine production process due to the lack of hygienic pigging systems. In response, we recommended using our sanitary automatic pigging system for medicine recovery. To address potential issues with the pig getting stuck, we recommended the use of 3D elbows instead of standard stainless steel elbows. The launching station would be installed at the outlet of the pump near the storage tank, and the receiving station would be installed right before the filling machine. Additionally, an automatic pig speed controller was necessary to ensure that the pig ran evenly along the pipeline.

To control the operation of each pipeline, we provided a standalone electrical control panel for each pipeline, totaling 19 panels. We also connected the new automatic system to the customer’s PLC system via Ethernet. The pigging system design was customized. Our team performed installation and commissioning, operator training to ensure a smooth transition. As soon as all the work was completed, the pigging systems were successfully running.

Overall, our solution helped REALCAN plant reduce waste and improve efficiency in their traditional Chinese medicine production process. By utilizing our innovative pigging solutions and providing expert installation and support, we were able to help this client achieve their goals while minimizing downtime and maximizing productivity.

LEARN MORE ABOUT OUR PIGGING PRODUCTS AND SOLUTIONS

Are you in need of hygienic pigging systems for your production of liquid pharmaceuticals? Do you want to ensure the safety and quality of your products while maximizing profits? We can provide you with detailed information on our innovative pigging solutions. Contact us today to learn more about how we can help you enhance your liquid pharmaceutical production process and achieve your business goals.

The project result

As a reputable engineering company, we prioritize responsibility, reliability, and customer-centricity in all of our projects. Good pigging helps savings. Our latest project involved the installation of hygienic pigging systems for a liquid pharmaceutical client. We not only delivered the project on time but also managed to reduce costs for our client.

Given the extensive installation work involved, we made every effort to use the least amount of pipes and fittings possible, thus saving our client money in the long run. In some instances, we even utilized piggable swingbends, which were both cost-effective and flexible.

We understand that as technology advances, our pigging automation and PLC programme may need to be updated in the future. However, it can easily be connected with the client’s existing major PLC system.

At HYPERFORE, we are dedicated to delivering top-quality pigging system projects and making reliable pigging systems and accessible to all end users who require them. We firmly believe that life is too short to work with unreliable partners. By prioritizing customer satisfaction and investing in cutting-edge technology, we aim to set ourselves apart as a leader in the engineering industry.

TESTIMONIALS

What Our Clients Say

5.0

Average Customer RatingRelated Cases

Hyperfore have many pigging system cases, pigging solutions cases, such as pigging system for food, pigging system for lithium battery slurry, pigging system for dairy, and so on.

Just contact Hyperfore!

Are you interested in sanitary pigging system, pigging products or pigging system for medicine recovery, looking for a reliable partner to fix your liquid processing problems? Please just feel free to contact us.