Custom Pigging Solutions & Turnkey Engineering Services

FROM HYPERFORECustom Pigging Solutions & Turnkey Engineering Across Various Industries

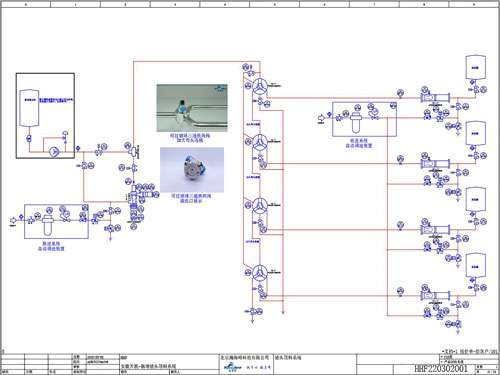

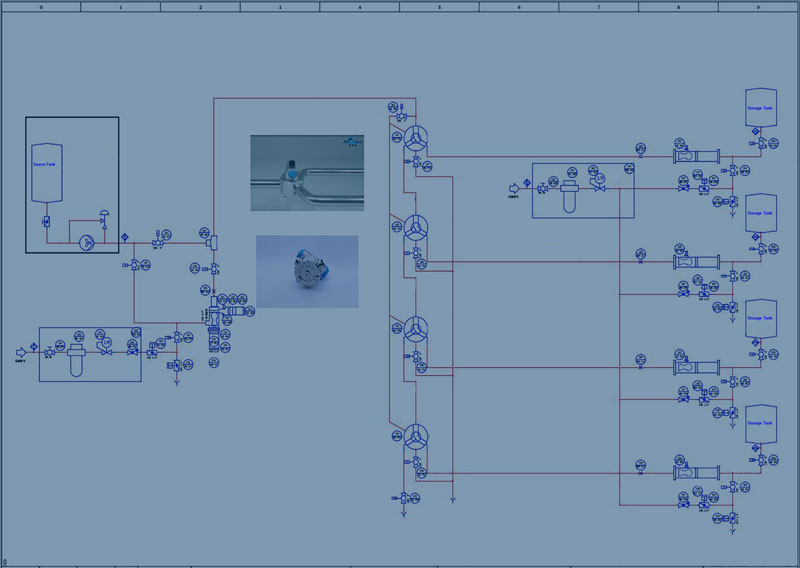

Process design is a central part of custom solutions and critical to a pigging system engineering. Meanwhile its correctness and timeliness is key to the success of a project.

Our engineers are professional team. We consult with customers sufficiently before we start the designing. We specialize in designing and implementing pigging systems that run efficiently. Our team is very responsible, we always oversee the timeline and cost, and deliver cost-effective projects on schedule.

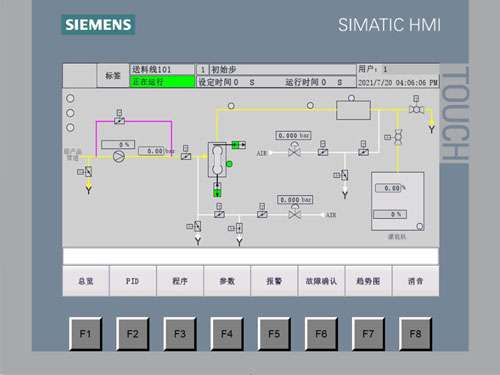

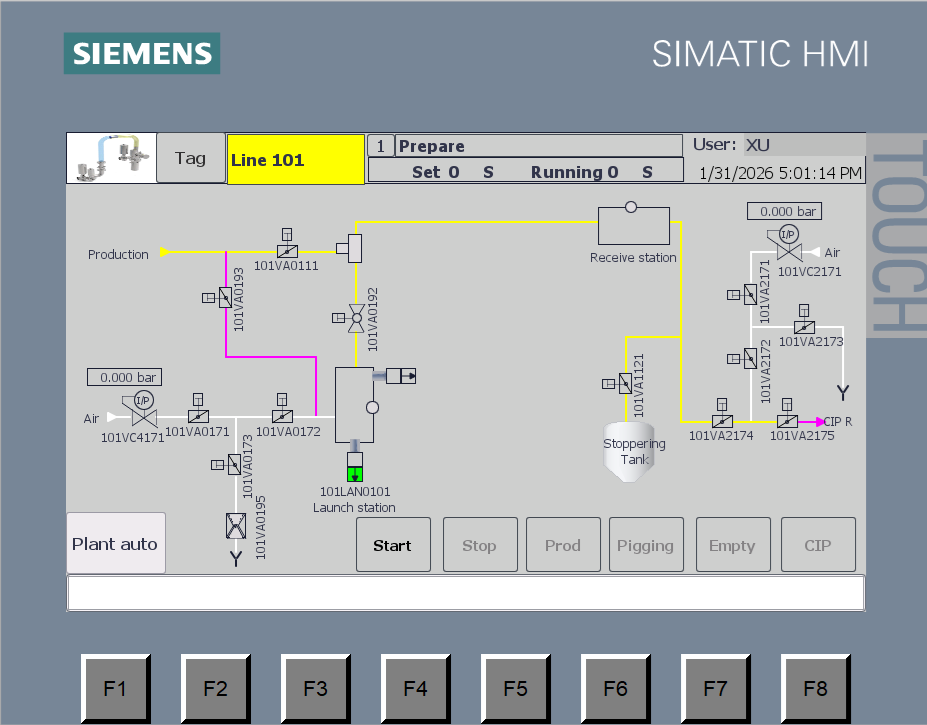

The Hyperfore automation team has extensive senior experience. They deliver top-quality automated pigging solutions and software to improve efficiency and speed for our customers.

We provide both standalone PLC systems and integrated PLC software based on customers’ actual needs. Our electrical and automation systems include control cabinet, HMI, SCADA and more. Since our foundation, we have implemented numerous successful automation projects. Turning many customers into long-term partners.

The installation and on-site start-up starts from correct positioning, cabling and wiring to the installed equipment. After a general conformity check with electrical diagrams, the automation engineer executes I/O test on each sensor, actuator, and all hardware. Then the PLC program starts the commissioning phase.

The Hyperfore team’s professional commissioning and installation guarantee the smooth operation of your plant.

Hyperfore remote technical support includes remote operating, monitoring, commissioning and training. It is convenient for customers requiring remote support anytime and anywhere. Especially for international customers, or those urgent situations.

Remote tech support offers an immediate solution to problems, saving significant time and costs associated with waiting for a technician to get to your plant.

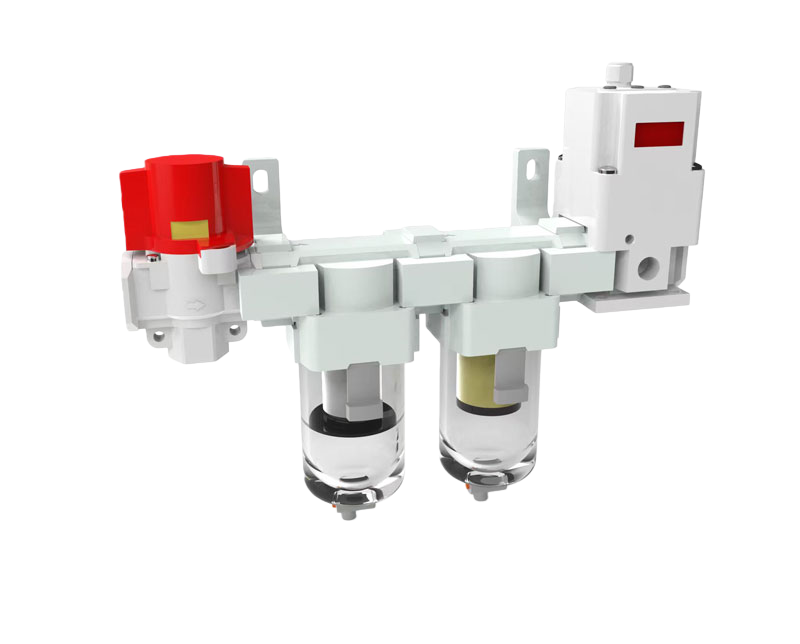

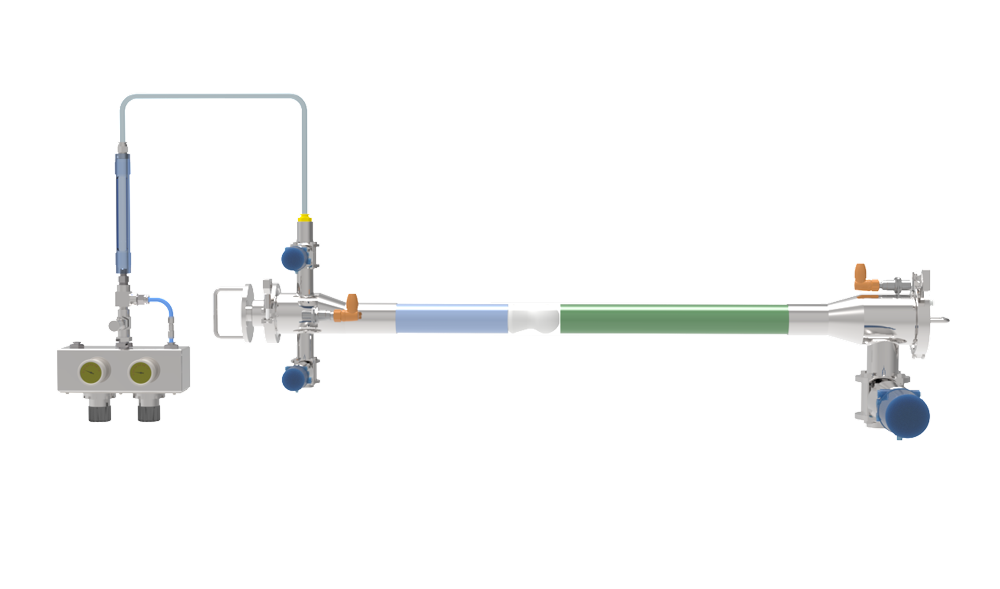

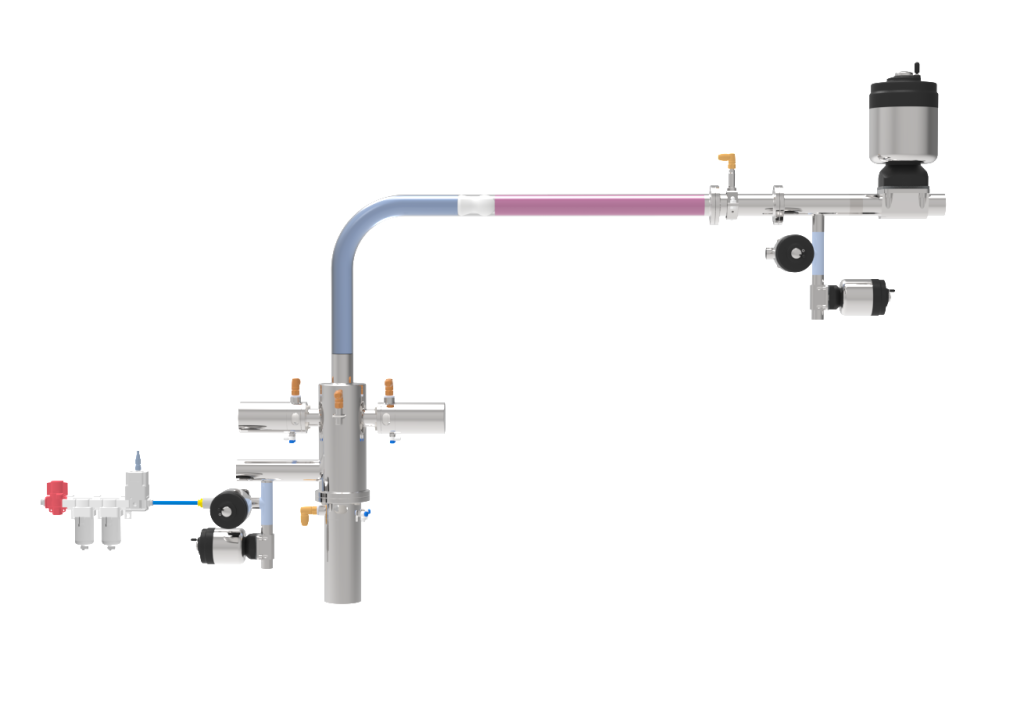

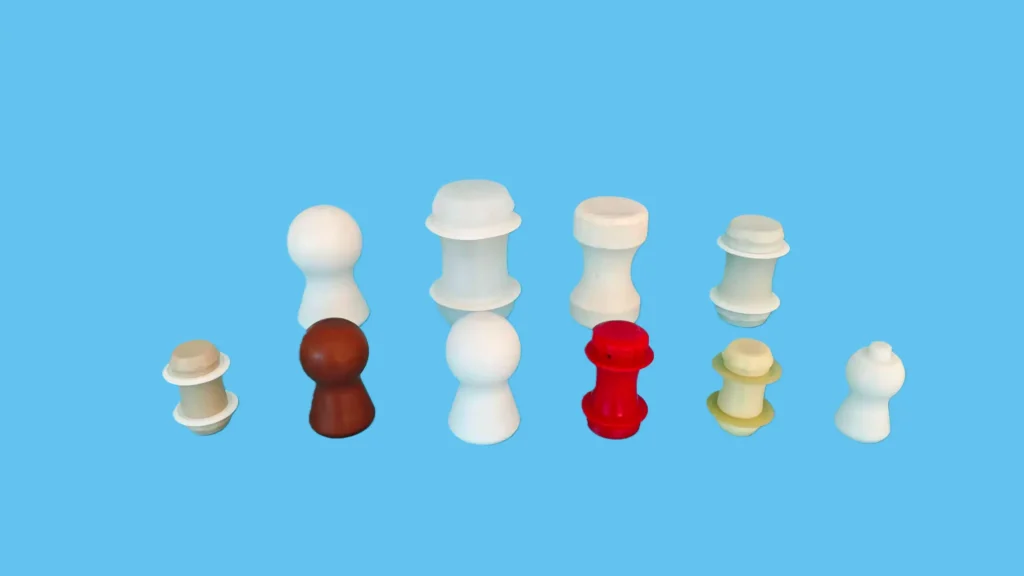

Hyperfore designs and manufactures sanitary and industrial pigging systems tailored to diverse liquid transfer applications. The customized solutions can reduce product waste and recover over 99.5% of the remaining products left in the pipeline.

Typical Pigging solutions

- Manual / automatic pigging solutions for food

- Aseptic pigging solutions for pharmaceuticals

- Double-pig system for paints & coatings

- Micro-residue pigging solutions for cosmetics

- Low-residue pigging solutions for chemicals

- Single-source to multi-destination configuration

- Multi-source to Multi-destination configuration

- Single-source to single-destination configuration

Beyond pigging system hardware, we are also expert in delivering end-to-end turnkey engineering projects for entire production line and entire workshop. Our comprenhensive engineering scope covers:

FAQ

Are you manufacturing liquid or powder products? If you are looking for rapid return on investment methods, we just have the solutions you need!