Ultra-Hygienic Aseptic Pigging System For Food, Dairy & Pharma

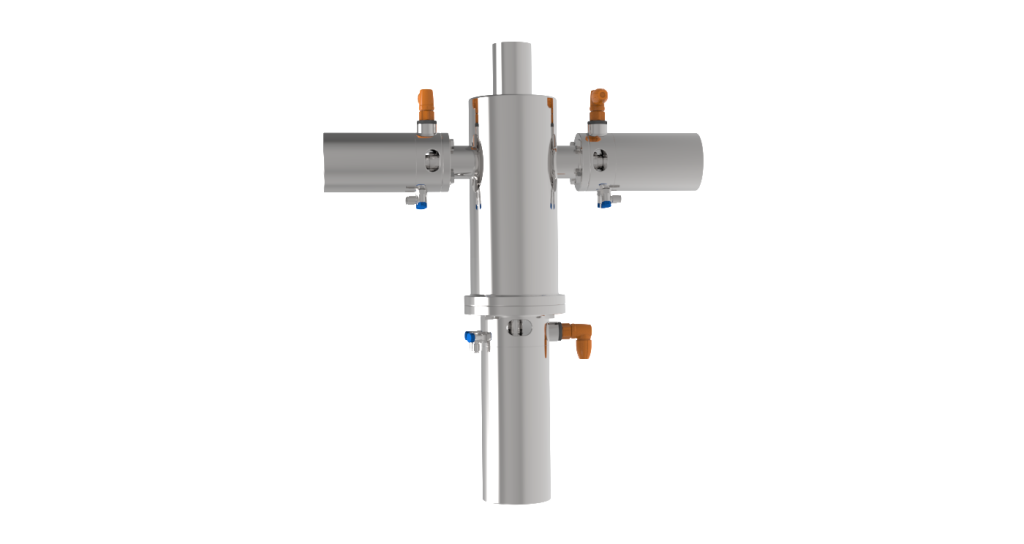

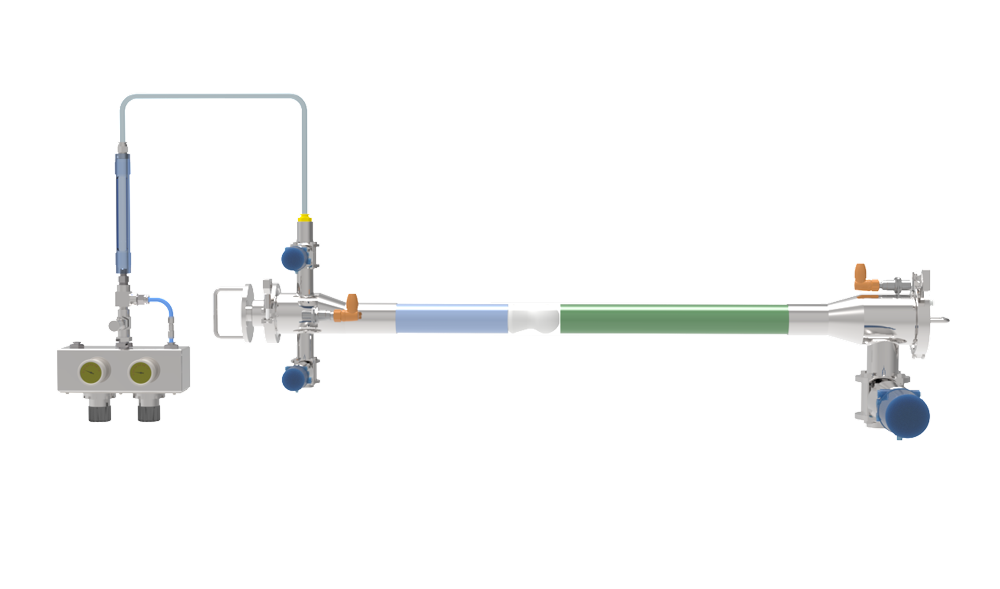

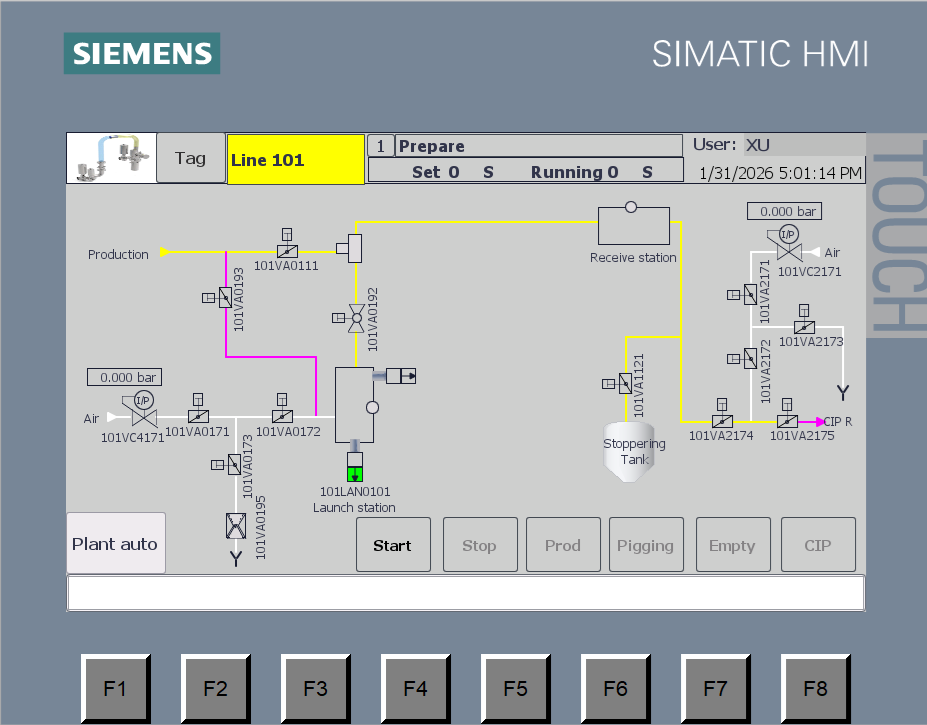

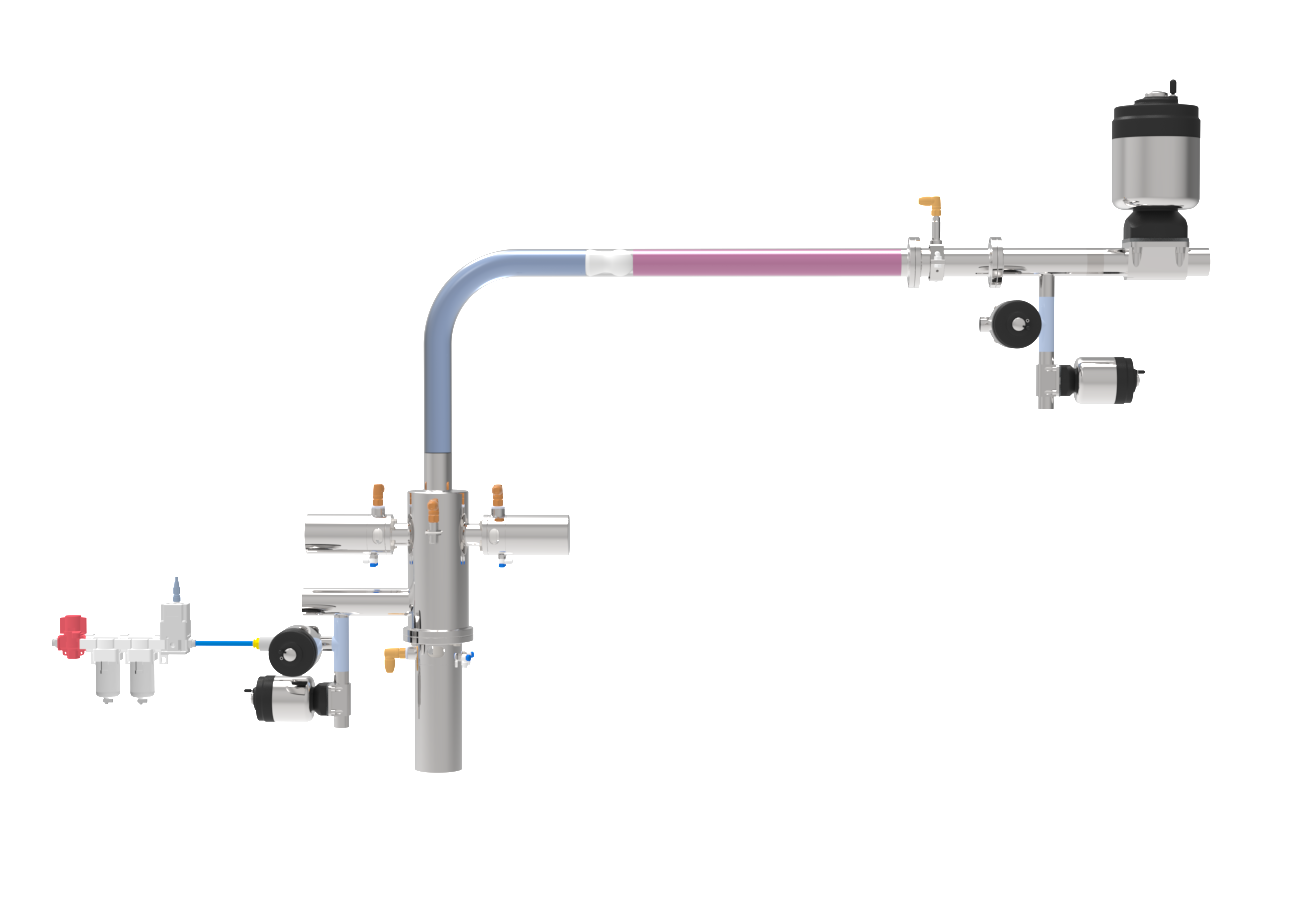

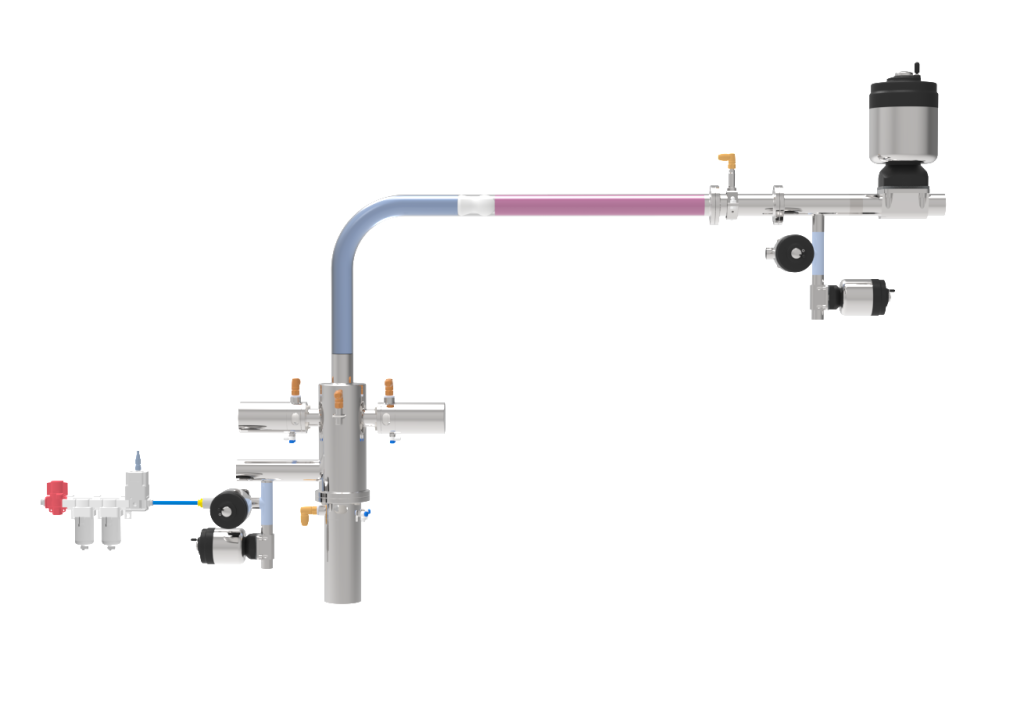

Given these stringent demands, choosing a pigging system that can satisfy the high-level hygiene needs is essential. Hyperfore aseptic pigging system is an ideal solution, recovering maximum high valued products out of the production lines. As the zero dead-leg design makes it a guardian of the sterility for the entire pigging system . Our aseptic pigging system not only serves an automatic cleaning method for pig pipes in sterile plants, but also makes fully closed piping system possible, enhancing the overall process integrity.

The aseptic pigging system is particularly suitable for for sectors demanding strict hygiene standards, including the dairy, pharmaceutical, food industries .

Key Advantages

Zero-Contact with Ambient Air

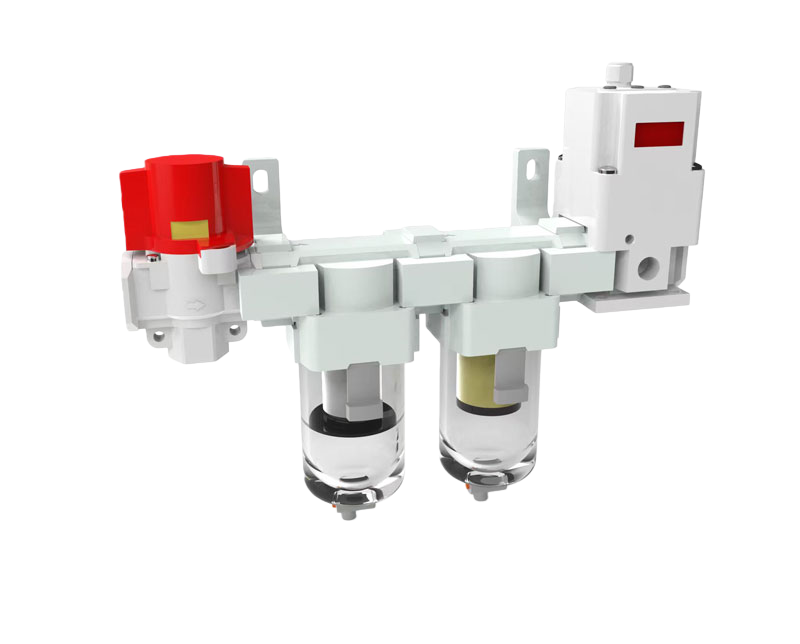

Hyperfore aseptic pigging systems feature an enclosed structure, bellow seal ensure isolation from the ambient Air

Material Safety

The system is constructed with FDA compliant and food-approved materials to ensure product integrity

Contamination Prevention

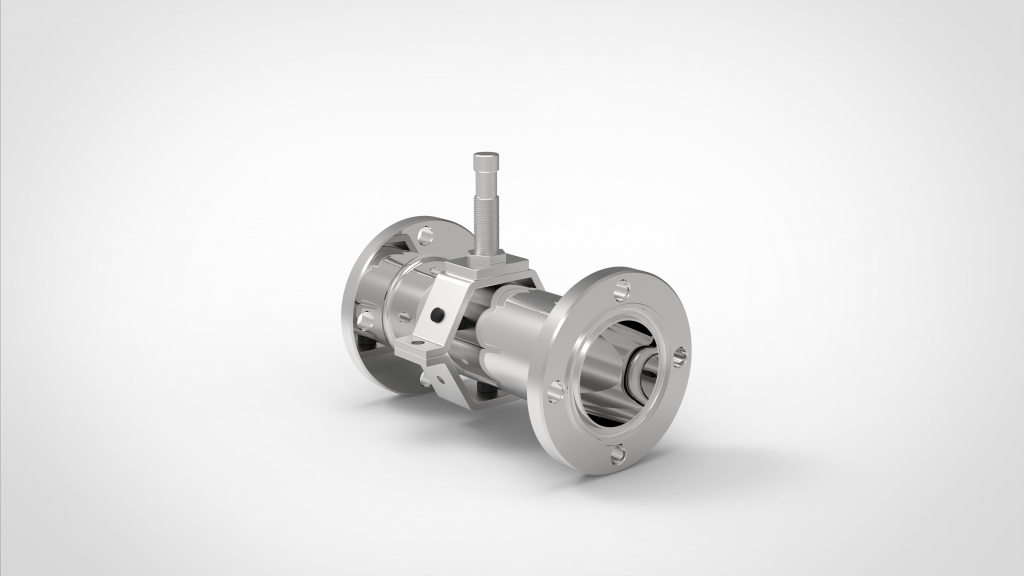

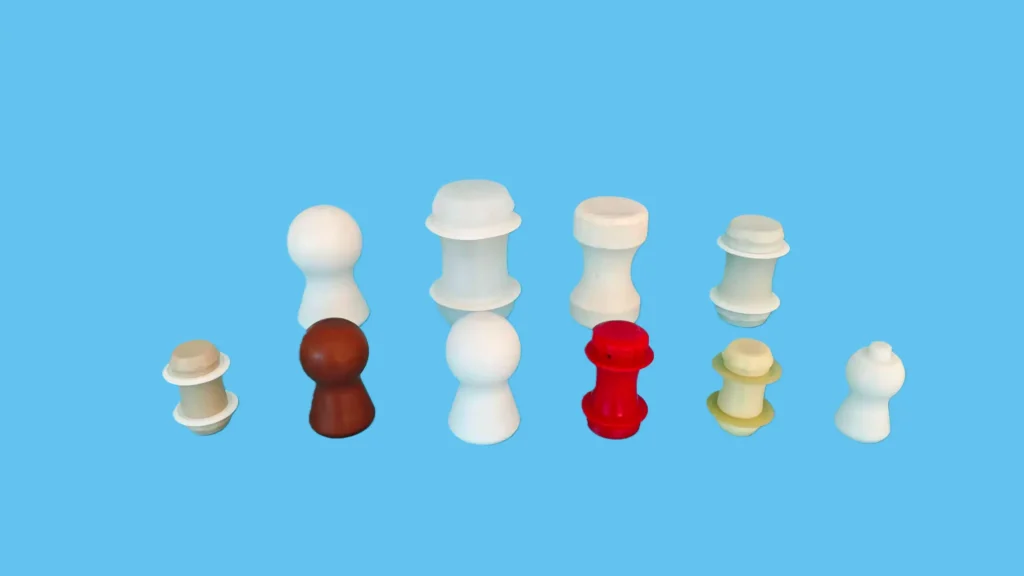

All product-contact parts feature SS316L, the pigs are Plasticizer-free and FDA-approved

Significant Benefits

Reducing water waste and treatment costs, reducing chemical detergent usage, shortening pipeline cleaning time

Dead-Space Free

The system features seamless internal profile that thoroughly eliminates spots that product could accumulate

SIP & CIP Compatible

The system is specially engineered to withstand high temperature and rigorous SIP (Steam In Place)process

Secure Product Safety With Hyperfore Aseptic Solution

Hyperfore aseptic (sterile ) pigging system is specially designed for sterile pipelines, such as medicine pipeline, dairy pipeline, and all sectors demanding strict aseptic production environment. In these industries, the pigging process must ensure aseptic operation all the time, otherwise, contamination may occur and compromize the product quality and safety.

Introduction

| DIN Pipe | DN40,DN50,DN65,DN80,DN100,DN125,DN150 |

| ISO Pipe | 1.5”, 2”, 2.5”, 3”, 3.5”, 4”, 5”, 6” |

| Material | 316L for surfaces contacting products |

| Pressure | less than or equal 0.8MPa |

| Polishing | Ra ≤ 0.8μ( surfaces contacting the product) |

| Temperature | less than 121°C |

| Sealing | EPDM, other materials upon requests |

| CIP&SIP | CIP compatible, SIP compatible |

Specifications

| Part Nr. | Size | OD * T |

|---|---|---|

| DGSSFBAD040A | DN40 | Φ41 * 1.5 |

| DGSSFBAD050A | DN50 | Φ53 * 1.5 |

| DGSSFBAD065A | DN65 | Φ70 * 2 |

| DGSSFBAD080A | DN80 | Φ85 * 2 |

| DGSSFBAD100A | DN100 | Φ104 * 2 |

| DGSSFBAD125A | DN125 | Φ129 * 2 |

| DGSSFBAD150A | DN150 | Φ154 * 2 |

| Part Nr. | Size | OD * T |

|---|---|---|

| DGSSFBAT038A | 1.5″ | Φ38.1 * 1.5 |

| DGSSFBAT051A | 2″ | Φ50.8 * 1.5 |

| DGSSFBAT064A | 2.5″ | Φ63.5 * 2.0 |

| DGSSFBAT076A | 3″ | Φ76.1 * 2.0 |

| DGSSFBAT089A | 3.5″ | Φ88.9 * 2.0 |

| DGSSFBAT102A | 4″ | Φ101.6 * 2.0 |

| DGSSFBAT127A | 5″ | Φ127.0 * 2.0 |

| DGSSFBAT152A | 6″ | Φ152.4 * 2.0 |

Specifications

| Part Nr. | Size | OD*T |

|---|---|---|

| DHRSFBAD025A | DN25 | Φ29*1.5 |

| DHRSFBAD040A | DN40 | Φ41*1.5 |

| DHRSFBAD050A | DN50 | Φ53*1.5 |

| DHRSFBAD065A | DN65 | Φ70*2.0 |

| DHRSFBAD080A | DN80 | Φ85*2.0 |

| DHRSFBAD100A | DN100 | Φ104*2.0 |

| DHRSFBAD125A | DN125 | Φ129*2.0 |

| DHRSFBAD150A | DN150 | Φ154*2.0 |

CONNECTION: FLANGE

| Part Nr. | Size | OD*T |

|---|---|---|

| DHRSKBAD025A | DN25 | Φ29*1.5 |

| DHRSKBAD040A | DN40 | Φ41*1.5 |

| DHRSKBAD050A | DN50 | Φ53*1.5 |

| DHRSKBAD065A | DN65 | Φ70*2.0 |

| DHRSKBAD080A | DN80 | Φ85*2.0 |

| DHRSKBAD100A | DN100 | Φ104*2.0 |

| DHRSKBAD125A | DN125 | Φ129*2.0 |

| DHRSKBAD150A | DN150 | Φ154*2.0 |

CONNECTION: CLAMP

| Part Nr. | Size | OD*T |

|---|---|---|

| DHRSFBAT025A | 1″ | Φ25.4*1.5 |

| DHRSFBAT032A | 1.25″ | Φ31.8*1.5 |

| DHRSFBAT038A | 1.5″ | Φ38.1*1.5 |

| DHRSFBAT051A | 2″ | Φ50.8*1.5 |

| DHRSFBAT064A | 2.5″ | Φ63.5*2.0 |

| DHRSFBAT076A | 3″ | Φ76.1*2.0 |

| DHRSFBAT089A | 3.5″ | Φ88.9*2.0 |

| DHRSFBAT102A | 4″ | Φ101.6*2.0 |

| DHRSFBAT127A | 5″ | Φ127.0*2.0 |

| DHRSFBAT152A | 6″ | Φ152.4*2.0 |

CONNECTION: FLANGE

| Part Nr. | Size | OD*T |

|---|---|---|

| DHRSKBAT025A | 1″ | Φ25.4*1.5 |

| DHRSKBAT032A | 1.25″ | Φ31.8*1.5 |

| DHRSKBAT038A | 1.5″ | Φ38.1*1.5 |

| DHRSKBAT051A | 2″ | Φ50.8*1.5 |

| DHRSKBAT064A | 2.5″ | Φ63.5*2.0 |

| DHRSKBAT076A | 3″ | Φ76.1*2.0 |

| DHRSKBAT089A | 3.5″ | Φ88.9*2.0 |

| DHRSKBAT102A | 4″ | Φ101.6*2.0 |

| DHRSKBAT127A | 5″ | Φ127.0*2.0 |

| DHRSKBAT152A | 6″ | Φ152.4*2.0 |

CONNECTION: CLAMP

Estimate Your Payback Period and Potential Savings

Aseptic product recovery is more than just hygiene—it’s a smart investment. Use the tool below to see how much you can save.

Frequently

Asked

Questions

Are you manufacturing food, dairy or pharma? Do you have trouble in securing product hygiene and contamination prevention? We have the answers you want!

Contact Us

Have questions about aseptic pigging system or solutions? Use the form to reach out and we will contact in 24 hours.