Pigging System Applications

Hyperfore sanitary pigging systems and solutions can be applicable across a wide range of industries and products in pipelines.

Key Applications of Pigging Technology In Various Sectors

In Dairy Sector

Hyperfore sanitary pigging technology can recover dairy products and minimize the risk of product contamination.

In Household Cleaner Sector

Hyperfore sanitary pigging solutions can largely reduce the production waste of shampoo, washing powder, cleaning detergent, toothpaste, etc.

In Food Sector

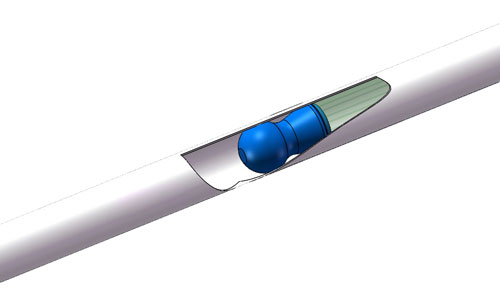

Sanitary pigging systems are made of SS316L, food-approved material maintain high level of food hygiene and safety.

In Viscous Products Sector

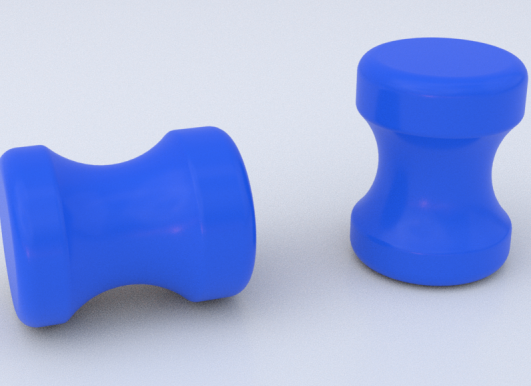

Pigging technology can be applicable to viscous liquid such as sauce, syrup, glue, paints, coatings, cream, etc. Bi-di pigs are used to reduce the residue to a minimum.

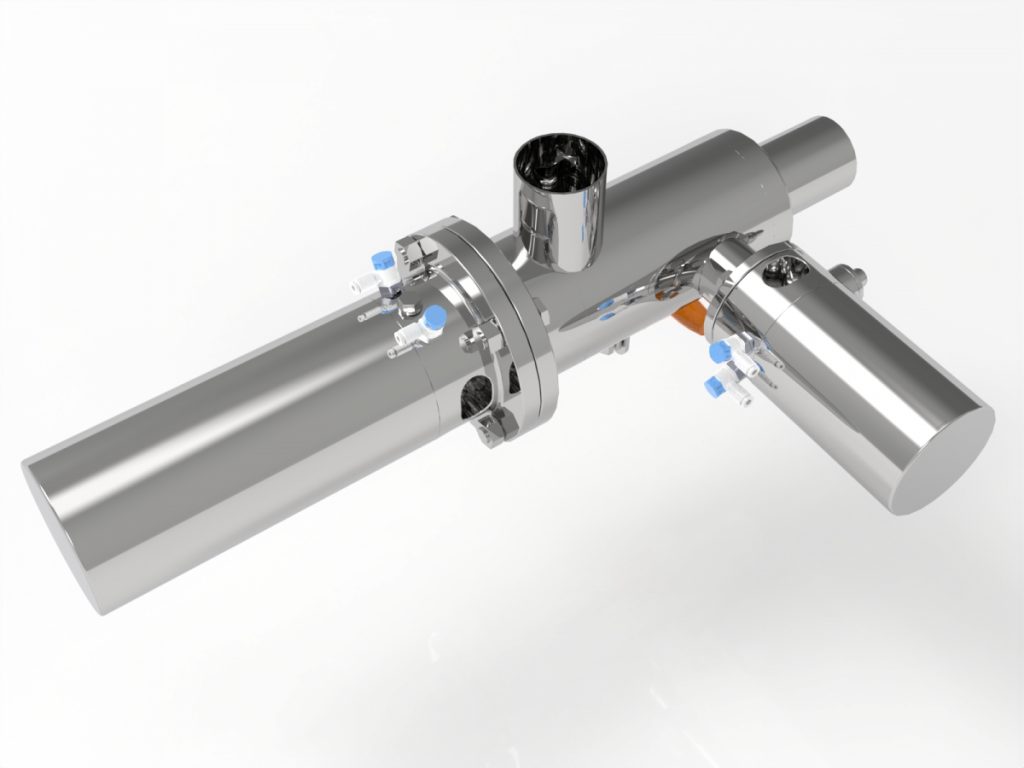

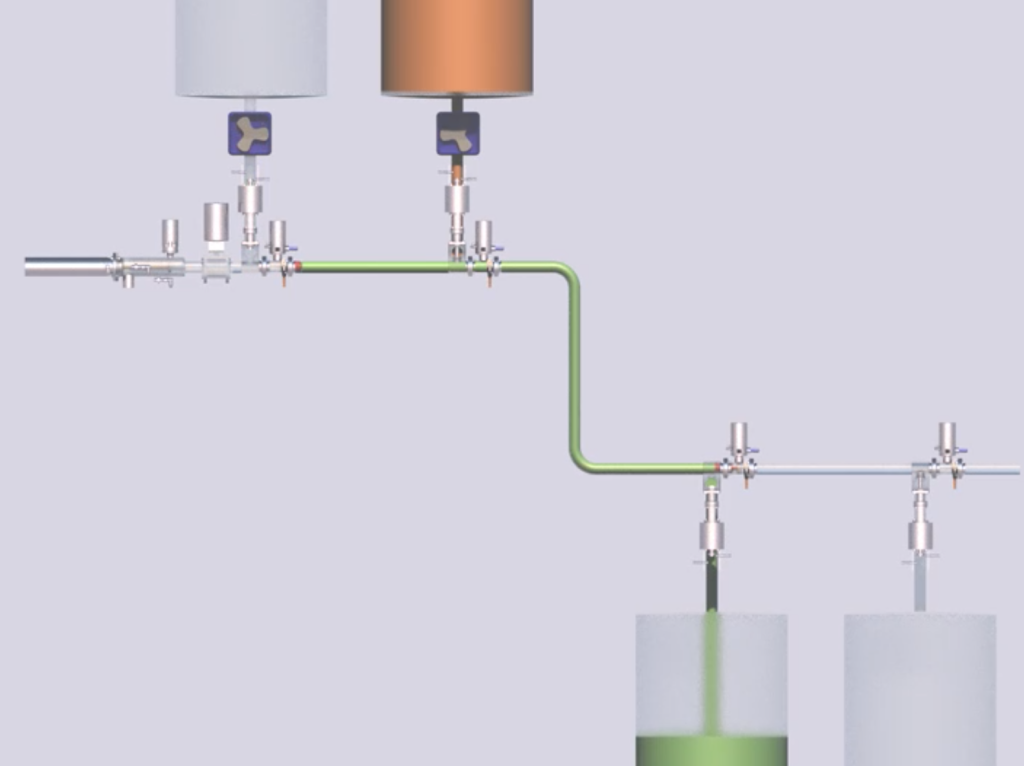

In Aseptic Pharmaceutical Sector

Hyperfore aseptic launcher and a close-looped pigging pipeline, the system guarantee an aseptic process environment.

In Chemical Products Sector

When choosing a pigging system for polyether, resin, etc.,factors like chemical compatibility, corrosiveness, explosion resistance are taken into consideration.

Our Advantages

Why Hyperfore is the best choice in pipeline pigging

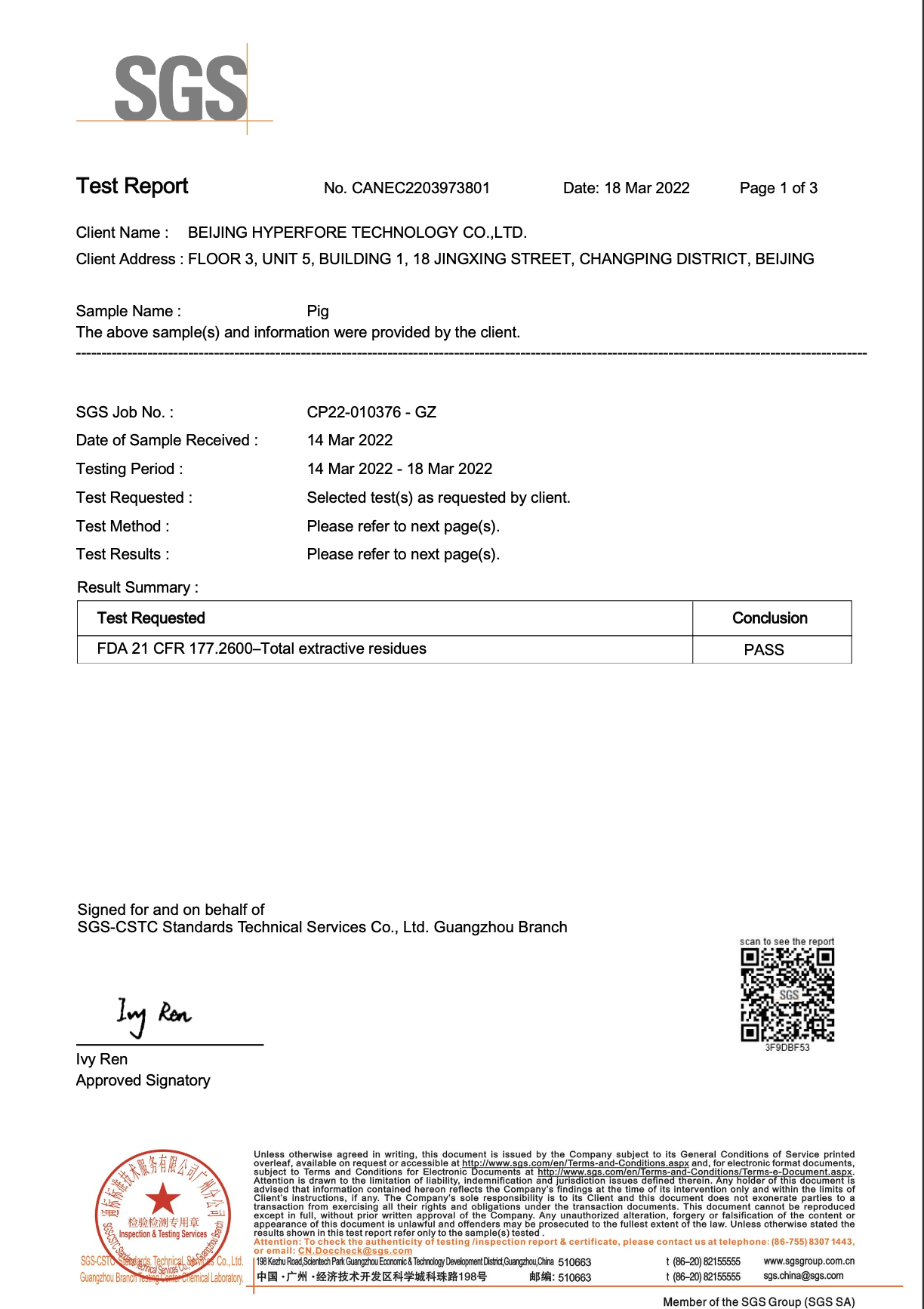

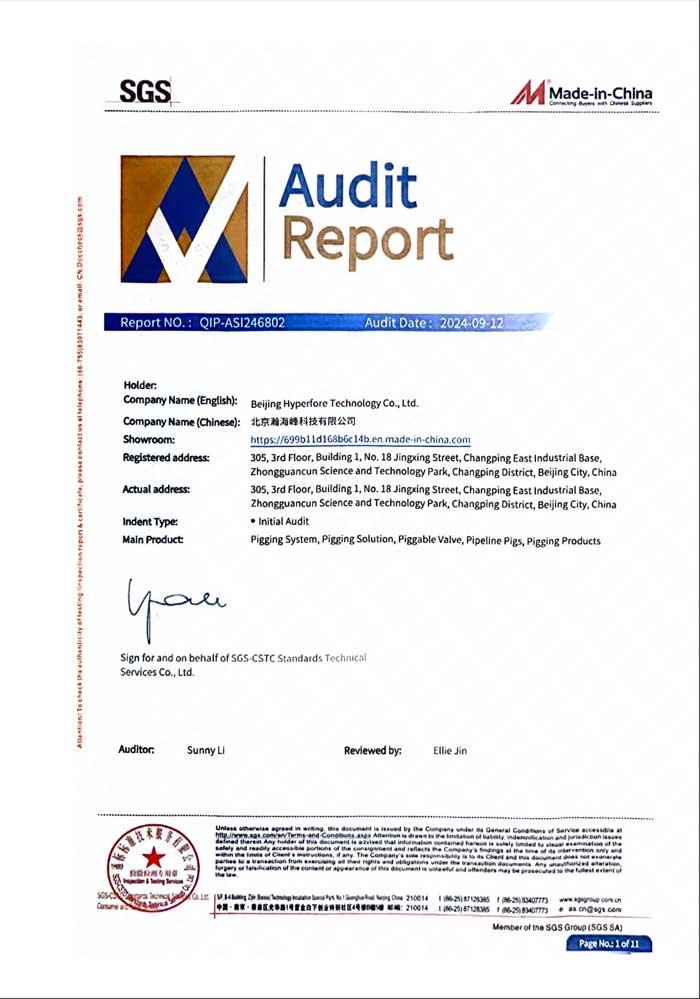

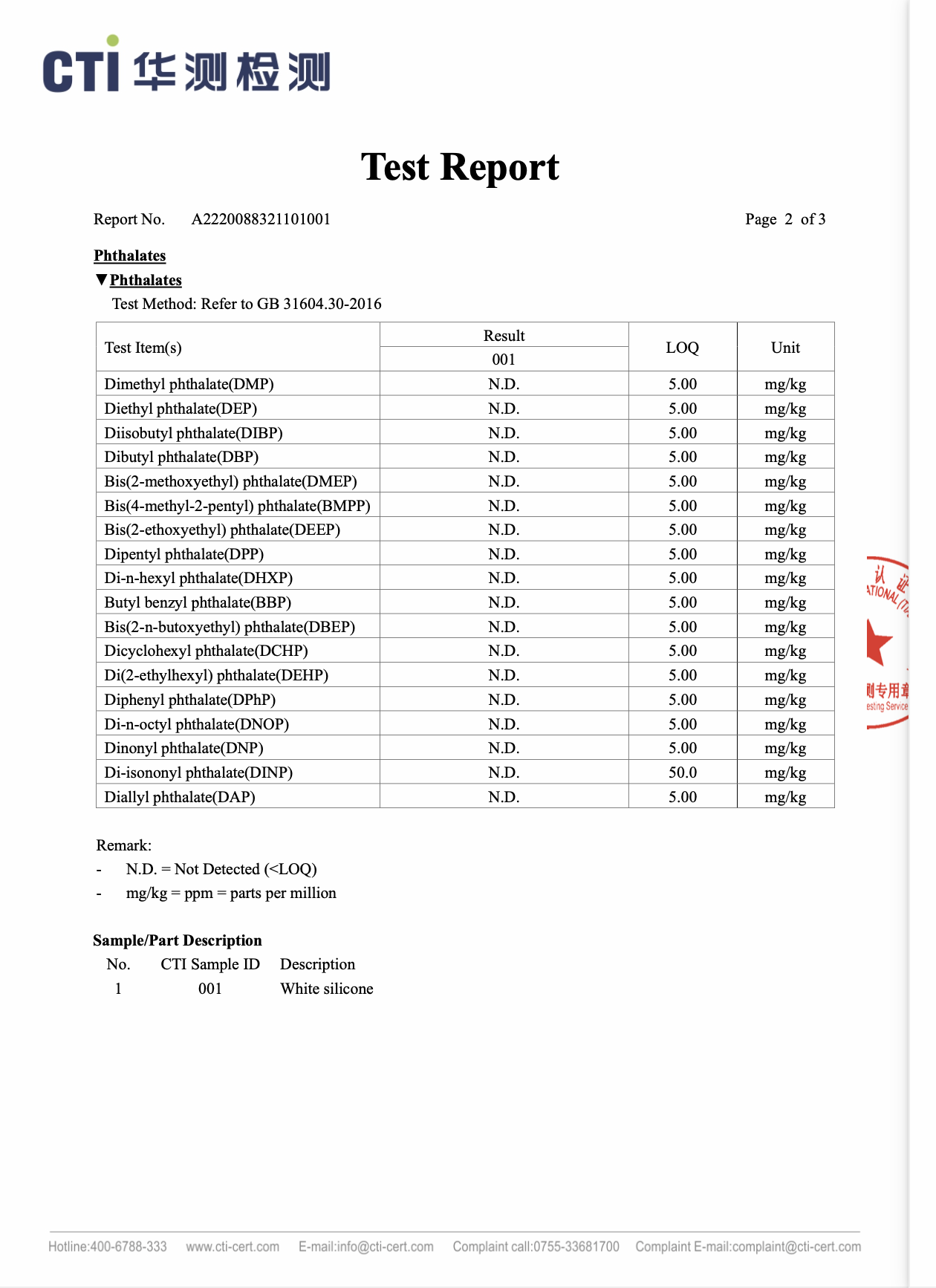

Certificates

As a professional sanitary pigging system and solutions supplier, we posses necessary certifications to meet different industry standard.

Pigging Products

Company Profile

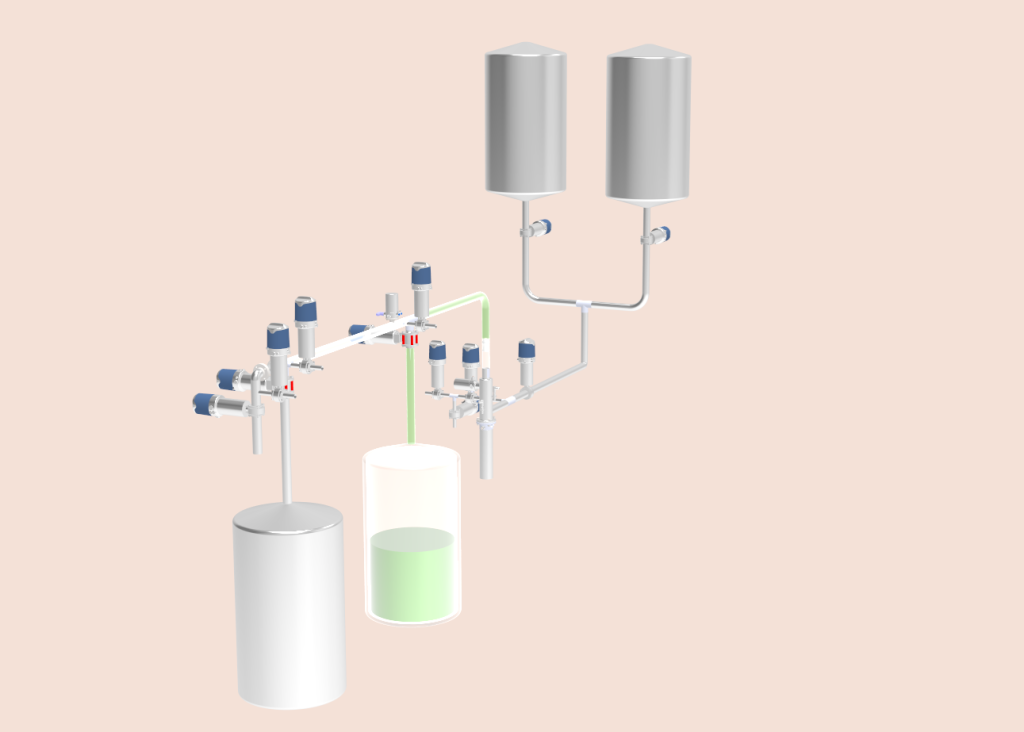

Hyperfore is a professional sanitary pigging systems and solutions supplier. We are sauce factory for sanitary pigging systems manufacturing. We boast rich experience of delivering high-quality turnkey pigging projects. Our dedicated engineering team can offer tailored pigging solutions including: pigging equipment and products(pig launcher, pig receiver, pipeline cleaning pigs), pigging process design, automation control, commissioning, installation and guidance, remote technical support, operating training.

Hyperfore has a proven track record of implementing successful pigging cases for both domestic and international clients, covering a wide range of industries. The pigging system applications include:dairy, drinks, alcoholics, household liquids, toothpaste, chemicals, pharmaceuticals, Chinese medicine, lithium battery slurry, paints and coatings, pigments and so on.

Our factory occupies an area of 2000 square meters, divided into four sections. The manufacturing workshop is equipped with advanced machineries, the assembling and testing workshop ensures high product quality, the warehouse is well organized to ensure optional storage and efficient logistics, and our office area is spacious and modern.

Our skilled team is mainly composed of experienced engineers, automation engineers, process engineers, installation engineers, mechanical engineers, purchasing engineers and so on. They have a proven track record in pigging system and liquid transfer engineering, and their extensive experience brings expertise to every project.

| Products | Specification | Value |

|---|---|---|

| Manual Pigging System Automatic Pigging System Piggable Diverter Valve Double Pig SystemAseptic Pigging System Aseptic Pigging System | Size | DN25-DN150, ISO1inch-ISO6inch |

| Material | SS316L, SS304 | |

| Control | Automatic, Manual | |

| Purity | Hygienic, Aseptic | |

| Pressure Range | PN6-PN10 | |

| Temperature Range | 0-121°C | |

| Surface Roughness | Ra0.8μm | |

| Recycling Rate | More than 99% | |

| Applications | Food, Pharmaceutical, Chemical, Cosmetic, Paints, Powder, etc. |