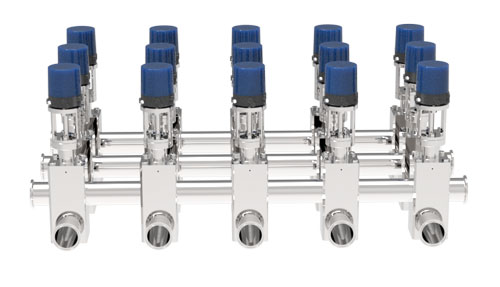

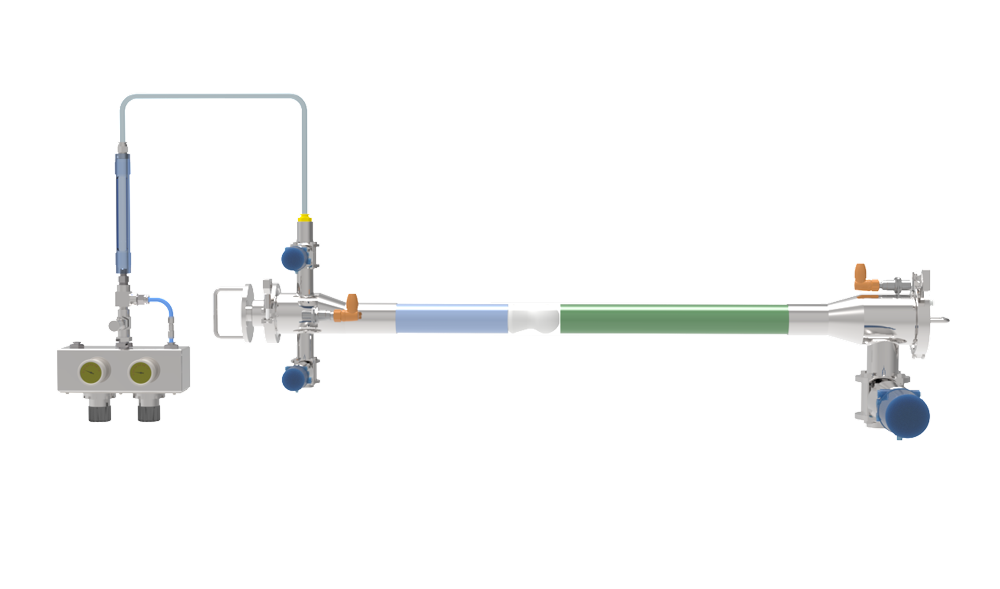

Automatic Sanitary Pigging Manifold

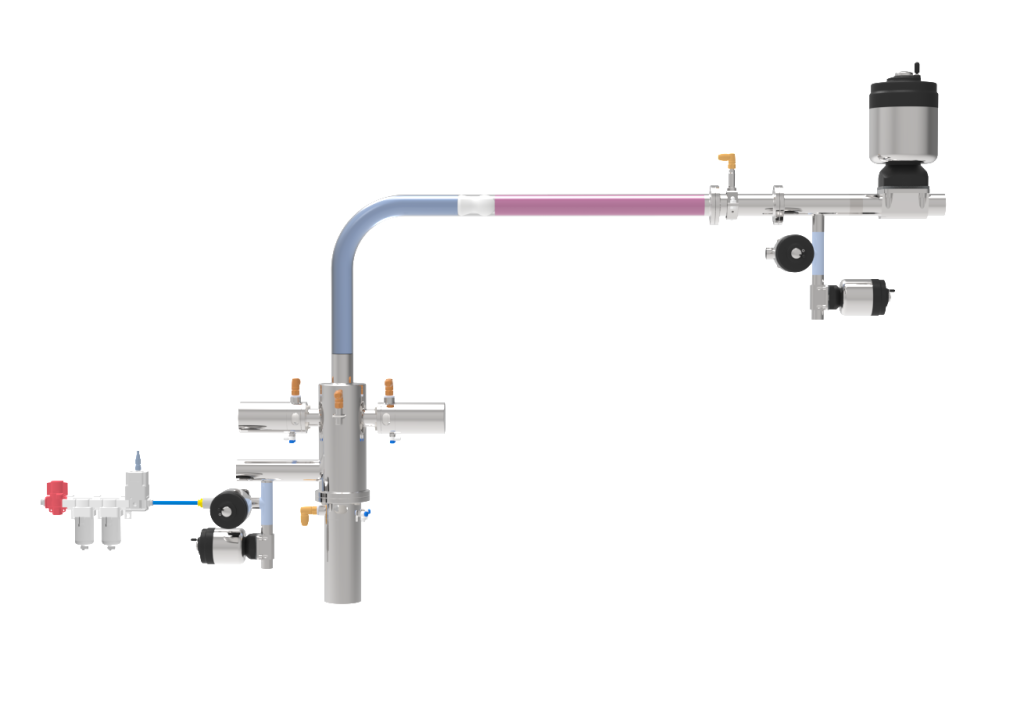

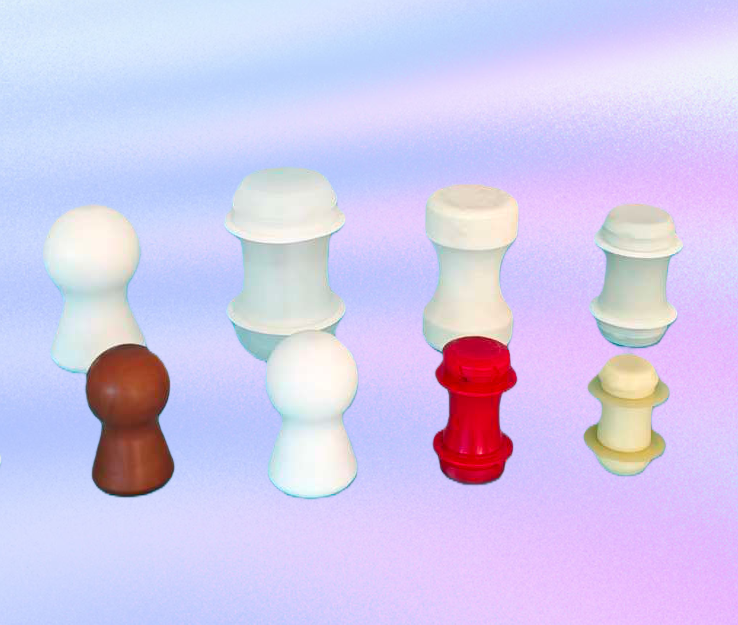

Our automatic piggable manifold is engineered for multiple products transfer and pigging process, it eliminates cross-contamination, and maximizes product recovery. The system ensures that the pig can smoothly pass both the upper and lower pigging pipelines, It is suited for wide span of industries, including cosmetics, food, toothpaste, paints and coatings.

Modular Design

Hyperfore piggable manifold features a one-piece modular design, quick and easy for one-site installation.

Optimizing Pigging

For multiple sources and destinations pigging, our pigging manifold flexibly simplifies the pigging process.

Zero Cross-Contamination

It minimizes coss-contamination between different batches of products.

Raising Efficiency

Efficient liquid conveying and pigging can be executed across both upper and lower pipelines.

Reducing Costs

Our pigging manifold reduces pipes and installation costs, largely saving expenses for enterprises.

Increasing Profits

Our piggable manifold increases profit for liquid processors by minimizing waste and reducing downtime.

Hyperfore Pigging Manifold Introduction

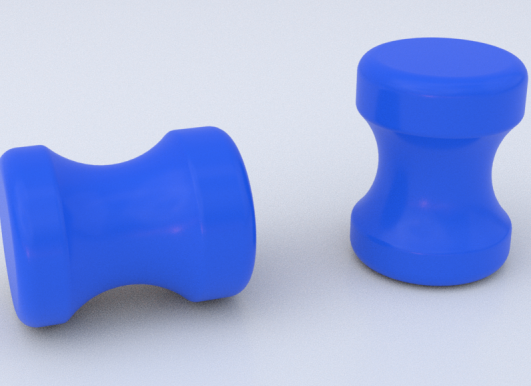

Hyperfore pigging manifold utilizes multiple piggable 4-way valves. It features automatic control.

For the 4-way valve, when the valve is closed, the upper and lower chambers remain independent;conversely, when the valve is open, they become interconnected.

Multiple such valves are integrated to create a dual‐layer valve manifold, forming independent piggable pathways for both upper and lower fluid transfer, thereby, minimizing product loss.

When the valves are closed, the upper and lower valve chambers separately establish a perfect pigging pipeline, ensuring the pig’s smooth passage. This design achieves ultra-low residue level and maximum recovery rate, directly meeting the stringent purity requirements of applications in sensitive industries such as toothpaste, shampoo, cosmetics paint, coatings, and dyes.

Our piggable manifolds is suited to a wide array of industries, including chemicals, paints, food, beverage, sauces, and more. They are suitable for high-volume of fluid transfer.