Hyperfore Custom Pigging Systems Portfolio and Solutions.

Hyperfore designs and manufacutures custom pigging systems, including sanitary and industrial pigging systems. These solutions ensure high efficiency , product integrity and maximum product recovery across a wide array of industries globally.

Maximum Product Recovery

Our customized pigging systems ensure that almost all residual product is converted into sellable product, guaranteeing immediate cost savings and improved yields.

Fast Return On Investment

Massive value recovered from minimizing product waste and extended uptime ensures your investment pays for itself fast, typically within a matter of months.

Customization Capability

Our pigging systems are tailored to your specific product media and pipeline layout, ensuring optimal performance to meet your processing targets.

Advantages of Hyperfore Pigging Systems and ROI

Our bespoke pigging systems offer substantial economic advantages, particularly for plants that transfer diverse products in long and shared pipelines.

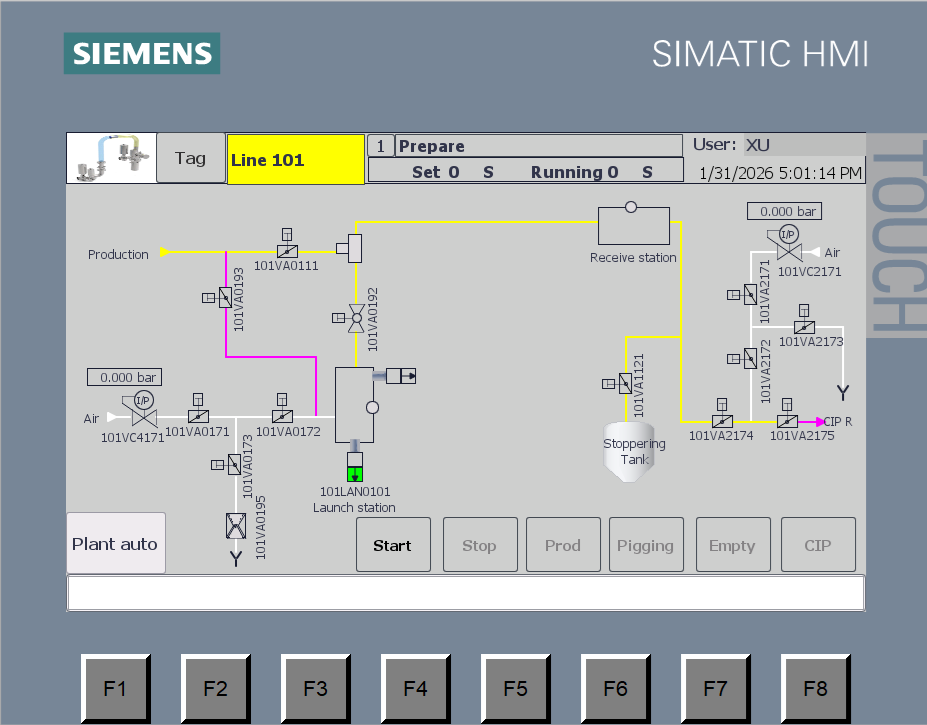

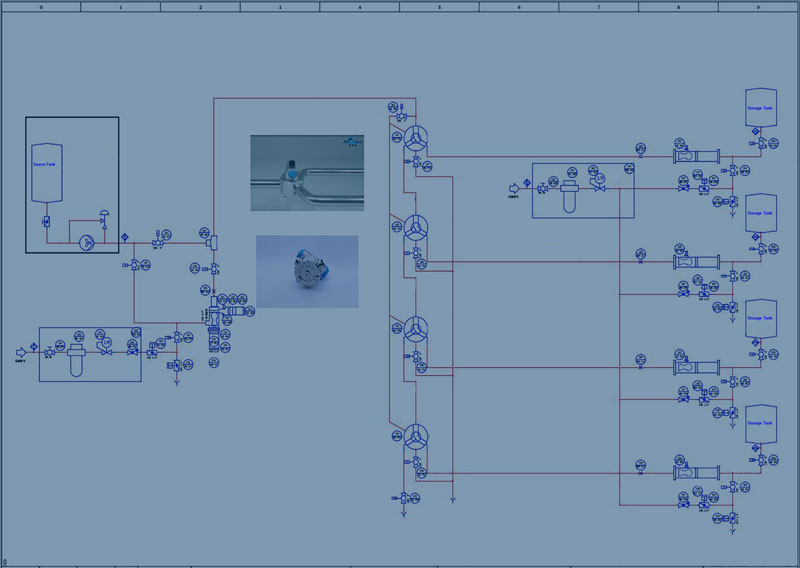

Hyperfore Pigging System Components and Working Process

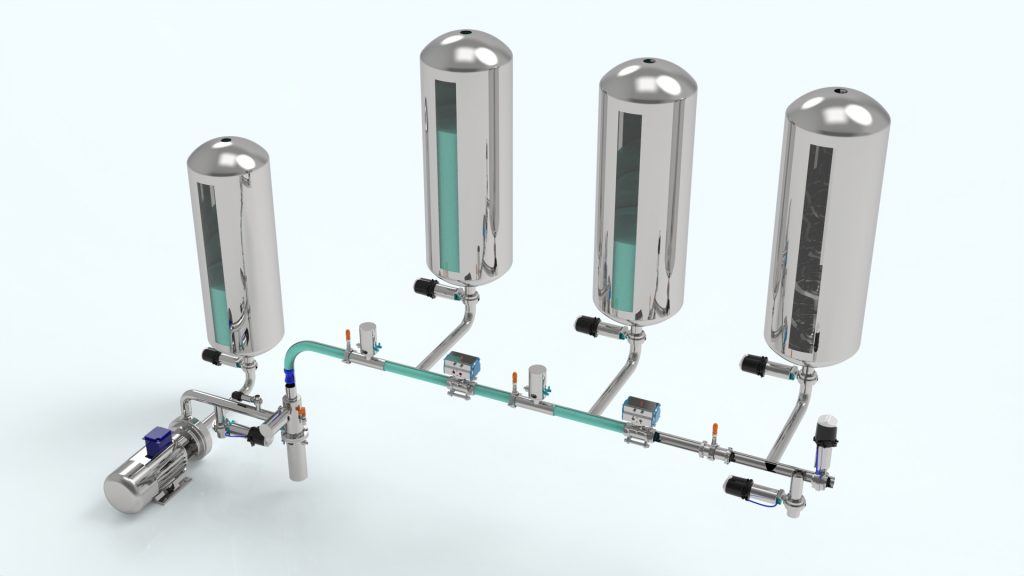

Custom Pigging Systems: Sanitary and Industrial types

Hyperfore provide various types of bespoke pigging systems. Through flexible configurations, we deliver tailored versatile pigging solutions, and they can be implemented across a wide array of industries and applications,including food, pharmaceuticals, personal care, detergents, chocolate, pet food, chemicals, lubricants, paints and coatings.

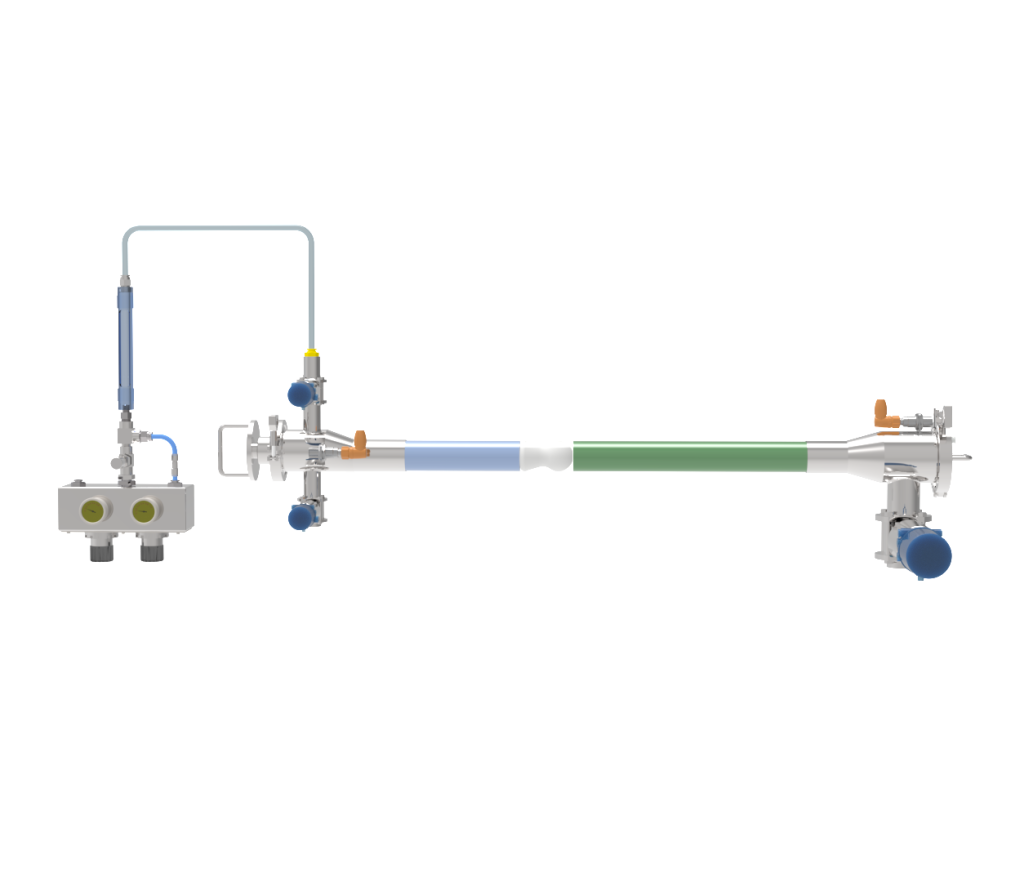

Flexible and Robust Manual Pigging System

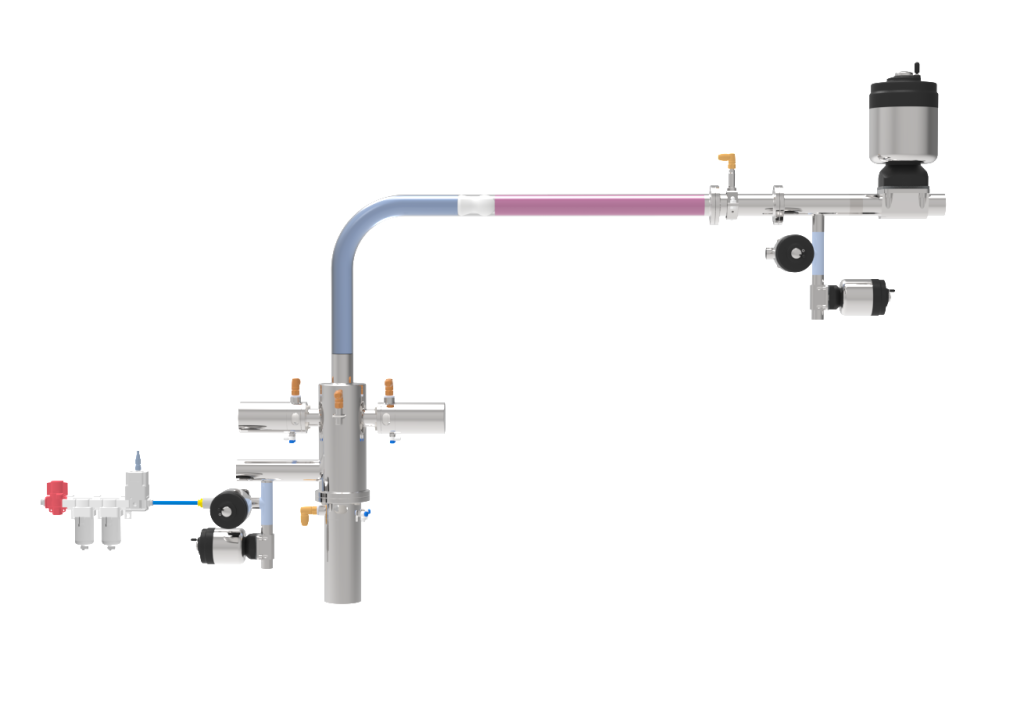

Automatic Sanitary Pigging System

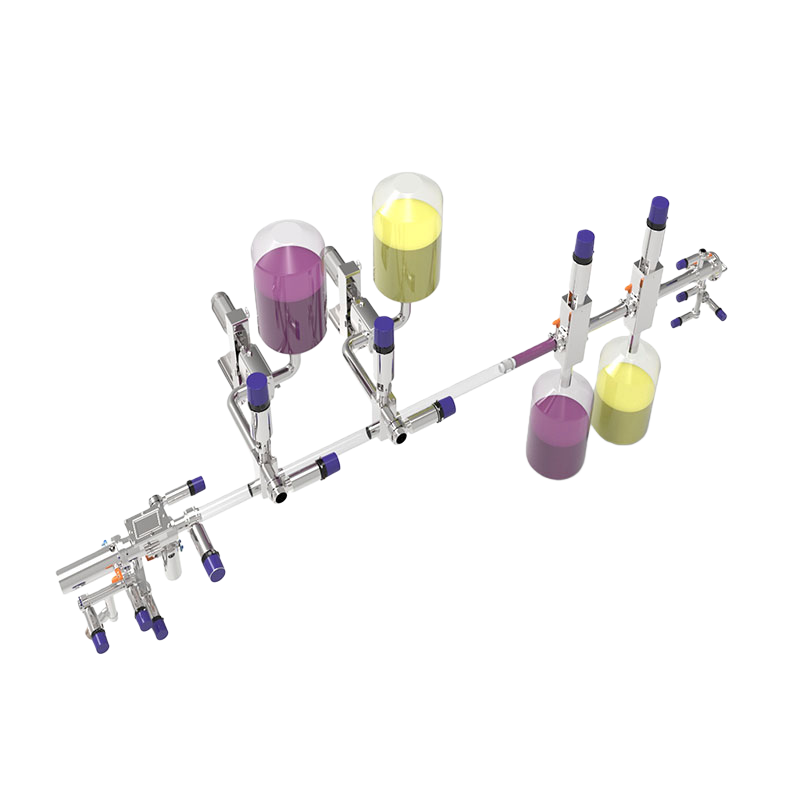

Aseptic Pigging System for High Purity Product Recovery

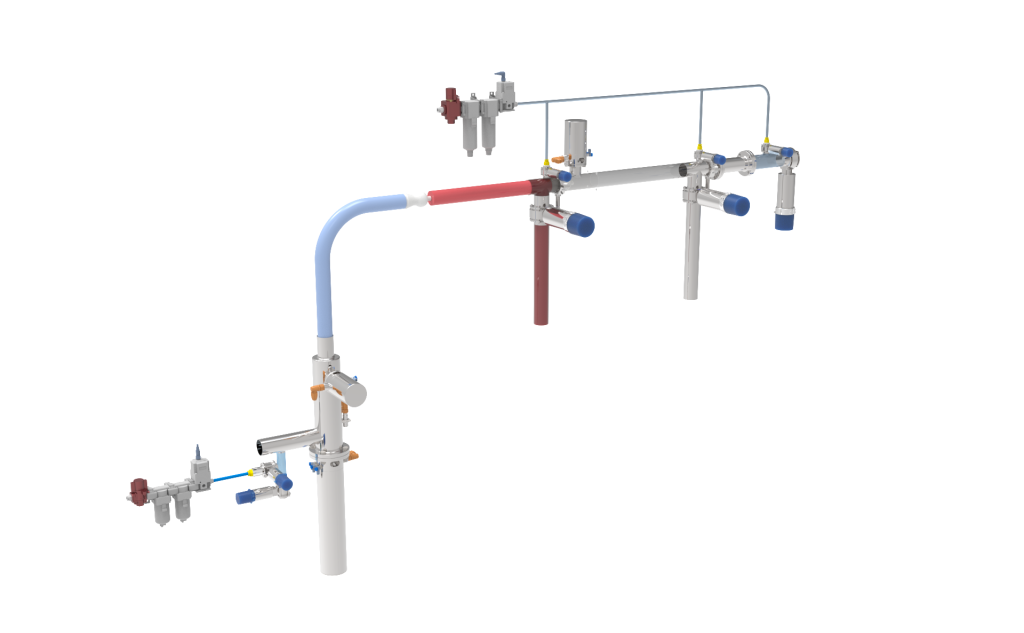

Micro-Residue Pigging System-Ultra Low Product Waste

Dual-Pig System for Complex Pigging Process

Key Applications of Custom Pigging Systems: Food, Pharma, and Industrial

Faq

Ready to Maximize Product Recovery and ROI?

Tell us your challenge—whether it’s labor costs, product waste, or extended downtime. We will show you how a custom pigging solution can cut your losses and deliver fast return on investment.