China Product Recovery( Pigging )Case Study : – Yong’s Food

Yong’s Food Used Pigging System To Recover Mayonnaise

Case Study- Pakistan Yong’s Food

How Hyperfore hygienic pigging system(product recovery system) help our Pakistan customer improve yielding, reduce waste, reduce cross contamination and enhance profit in mayonnaise production.

Summary

Hyperfore designed, supplied a fully automatic 3-inch sanitary pigging system for a Pakistan customer. They also provided remote technical support during the installation and commissioning of this system. This innovative pigging solution effectively reduced mayonnaise waste, improved yield, and enhanced the cleanliness of the manufacturing lines.

In addition to these benefits, pigging has accelerated the changeover process, leading to improved operational efficiency. By conserving energy and resources, Hyperfore’s pigging solution has contributed positively to the company’s competitiveness and commitment to environmental sustainability. The customer was highly satisfied with the system’s performance and appreciated the remote technical support provided by Hyperfore throughout the installation and commissioning process.

About Yong’s Food

The House of Young’s started its operations in 1988 as a food processing establishment in Karachi, Pakistan. The first product launched by Young’s was Mayonnaise which received tremendous acceptance and appreciation from Pakistani consumers. Another milestone in spreads category was “Young’s Chicken Spread” which was launched in 1989. Young’s was the first company to commercially manufacture Chicken Spread in the world. The journey of successful launches continued with Sandwich Spread, Chocolate Spread, Olive Spread, Mayo Garlic and Natural Honey. Today, Young’s enjoys successful brand leadership in Mayonnaise and Spreads category throughout Pakistan. Young’s is remarkably spreading in various parts of the world.

The Customer Wanted Us To Deliver a Cost-Effective Pigging System

Young’s Food is a large food processing company based in Pakistan that deals with the production and distribution of various food products. The company has recently faced some challenges with their pigging system, which they had purchased from another provider. The pigging system cost is a considerable amount of money, yet Young’s Food was not satisfied with its performance. As a result, the company decided to find a more cost-effective pigging system for their mayonnaise recovery process.

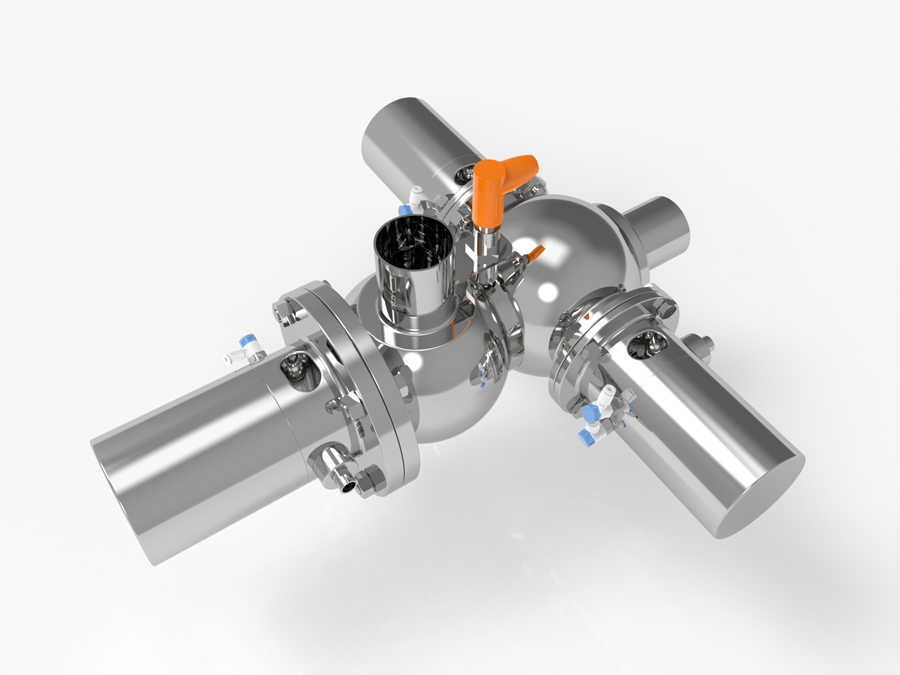

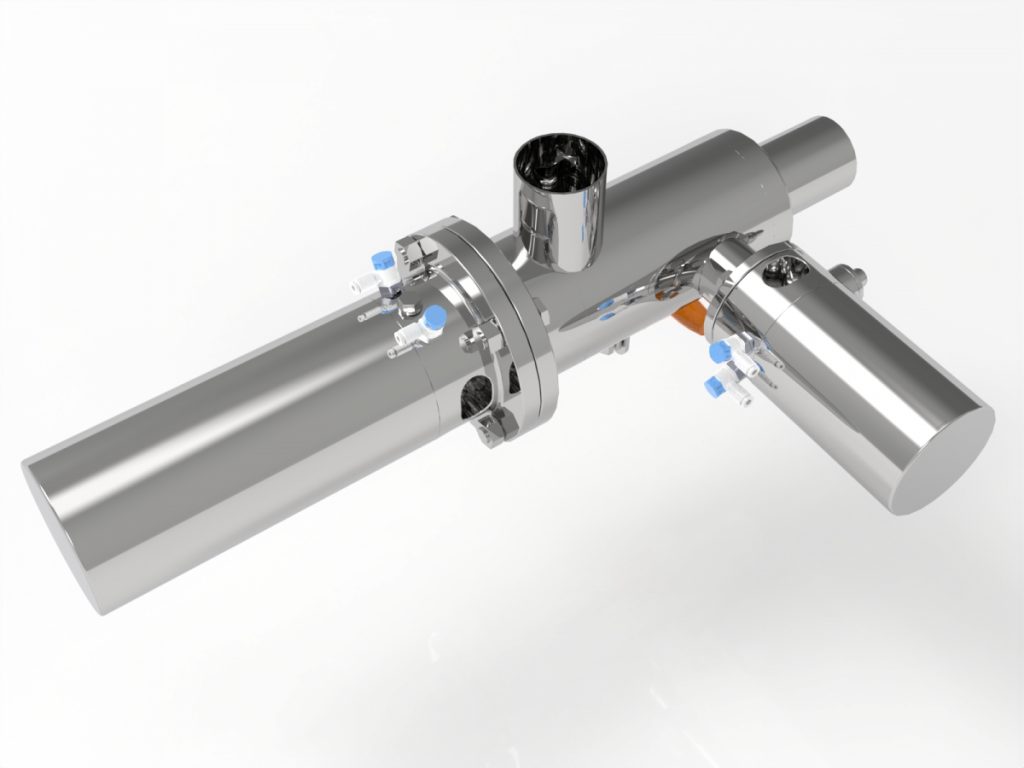

After thorough research and analysis, Young’s Food finally reached out to Hyperfore to understand their specific requirements. According to them, the production tank and pump are located on the second floor, while the receiving tank and filling machine are situated on the first floor. The customer needed a piggable 3-way diverter valve on the loft floor that would allow the pigs to pass through while unqualified products could be dumped through the valve.

In order to address this requirement, Hyperfore proposed an automation system that would include an electric cabinet, automatic pigging system, and remote technical support. Our solution aimed to provide Young’s Food with a more efficient and cost-effective pigging system that would enhance their overall production process. By leveraging our expertise and experience in the food processing industry, we are confident that we can deliver a solution that meets their needs and exceeds their expectations.

In conclusion, Young’s Food’s pigging decision to pig the mayonnaise production line , and seek a better automated pigging system highlights the importance of finding innovative solutions that not only improve efficiency but also reduce operational costs. Hypefore is a reliable and experienced supplier, we can help companies like Young’s Food achieve their goals and thrive in today’s competitive market.

Hyperfore Provided a Tailored Automatic Pigging Solution

As per the design plan, we installed the automatic launching station after the pump outlet. The 3-way diverter valve was then installed on the loft floor, which lies between the first and second floors. The outlet port was connected to a soft pipe to discharge the waste product. Near the receiving tank, we installed the automatic receiving station, and beside the launching station, we placed the pig speed controller. We suggested to our customer that the compressed air source should be located near the pig speed controller for efficient functioning.

During the mechanical and electric installation process, our customer contacted us for remote guidance. We provided them with relevant support via the internet to ensure smooth functioning of the system. We also offered advice on electrical wiring and piggable 3-way valve connections to ensure proper setup and avoid any technical glitches.

By providing an automated pigging system that is cost-effective and efficient, we aim to contribute towards the growth and success of our customers’ businesses. Our commitment to delivering quality solutions at every stage of the project has enabled us to build long-lasting relationships with our clients and gain their trust and confidence.

The Result and Customer Reviews

The pigging system for the mayonnaise pipeline has been performing exceptionally well. It pigs the 3-inch pipeline twice daily, which is approximately 100 meters long. This means that the pigging system for mayonnaise recovery is highly efficient and has already saved around 4000 yuan per day and 120000 yuan per month. Our customer has also praised the automation control system, stating that it is convenient, efficient, and flexible. The operation interface of the pigging system is visually appealing and displays the equipment’s operating status in real-time. In case of any emergencies, the system reacts promptly, ensuring that the production process remains uninterrupted.

Our remote technical support, which is part of our pigging system automation, has also helped overcome communication barriers between our two countries. Customers can monitor the production status from anywhere using their mobile phones or tablets. If they require assistance, we are just a click away, and we respond promptly over the internet. We answer questions, provide installation advice, and offer operational training to ensure that our customers operate the system with ease.

Our customer was highly satisfied with both our products and services. They commented, “We found their ability to be excellent. Hyperfore’s design is correct and cost-effective. Moreover, the pigging automation is user-friendly and reduces human errors. Most importantly, their automated pigging system and service are top-notch.” Overall, we are delighted to have received such positive feedback and look forward to continuing to provide our customers with exceptional solutions.

LEARN MORE

Are you considering to install hygienic pigging system for mayonnaise or food recovery on your productions lines, do you want to save your products, please get in touch with us for detailed information.

Related Articles

Hyperfore have many pigging system cases, pigging solutions cases, such as pigging system for food, pigging system for lithium battery slurry, pigging system for pharmaceuticals, and so on.

Let us know how we can help you!

Hyperfore is a professional pigging system manufacturer and pigging solutions provider. Our pipeline product recovery system is hygienic.They are widely used in food, drinks, dairy, pharmaceutical and other industries. If you are interested in our pigging system case, just contact us.