What Is Pigging

And How It Works?

What Is Pigging From Hyperfore?

Pigging refers to using a kind of special equipment called pigging system (or product recovery system) to recover valuable food products or powder medium inside the pipelines in the workshop in different liquid processing industries. The industries include: diary, beverage, chocolate, pharmaceuticals, sauce, pet food, meat paste, chemicals, lithium battery slurry, painting, even powder and so on.

Where Is Pigging Applied?

Pigging has been widely applied to many industries, including: diary, beverage, chocolate, pharmaceuticals, sauce, pet food, meat paste, chemicals, lithium battery slurry, painting, even powders and so on. These above are industries Hyperfore pigging system are applied.

Normally in a plant, the liquid transfer process is like the following: the liquid product with high viscosity (such as syrup) is pumped into the pipes by rotor pumps or screw pump, and less sticky liquid product (such as water, milk) is pumped by centrifugal pump. The pump process is to help liquid product move from the original tanks to the destination tanks or the filling machines.

But there are two main reasons that make the pump unable to finish the work independently. First, the liquid at the pump outlet can be pushed when there is a continuous flow of liquid behind it,and when the pump sucks in air, the liquid at the outlet can’t be pushed to move in the pipes further more. Second, some liquid medium or products are very sticky, they may stick on the inner wall of the pipes.

As a result, there always be some liquid products remained inside the pipes, and that is why pigging process is used.

Hyperfore Pigging is used to scrape off the residue liquid product stuck to the pipe walls, and then push it to the corresponding target tanks, reducing waste and enhance productivity.

How Pigging Works?

The Process of Pigging

When the pipeline is transporting liquid medium for production, the pigging system doesn’t work. It starts working after production, and at that time, there are plenty of residue product left in pipe, even stuck to the wall of the pipe.

Pigging system operation can be manually operated or automatedly operated. We recommend automatic operation, because it is more efficient and effective. At the beginning, the pig is in the launching station. It is pushed to move along the pipe by the driving force generated from the compressed air sauce. As the pig is going along the pipe, it scrapes off the residue product stuck on the pipe wall, and it pushes the product to the destination tank for filling or production. When the pig arrives at the receiving station, the product recovery process ends, and the pig can return to the launching station for CIP or next round of pigging operation.

What Are the Benefits of Pigging?

The pigging process provides a lot of benefits to the users and especially the liquid product manufacturers.

Pigging Can Improve Productivity

The pigging process help reduce product waste, recover and gather almost over 95% of the residue liquid along the pipelines, the result definitely can enhance productivity.

Pigging Can Enhance Efficiency

The pigging process is normally conducted by automation system. As we all know, automation operation can raise efficiency, make the product recovery process faster, and because the whole process need no manual operation, less human errors happen, so the production efficiency is improved.

Pigging Process Helps Save Cost

The price of a sanitary pigging system is not very high, yet it can save a lot of money. Before using pigging process, all the residue liquid medium inside the pipelines has to be wasted. Moreover, after one batch of production, the pipes have to be cleaned thoroughly to be ready for another batch of different product. Then the question comes, how to clean the pipes? The answer is using CIP: the manufacturers have to use cleaning detergent and plenty of water to flush the residues product away. The cost of CIP is very high. After pigging process is applied, the residue products remained in the pipes become little, even using CIP, the cost drops significantly.

Pigging Process Reduces Cross-Contamination

Before a different product enter into the pipeline, the pipes have been cleaned thoroughly by pigging process. Using pigging process, the cross-contamination risks are largely reduced. And product quality is well guaranteed.

Pigging Process Is Environmentally Friendly

Sewage discharge is always harmfully for the environment. After the pigging process is applied, less cleaning agent is used, and less polluted waste water is generated, less river and earth is polluted. Meanwhile, water is always precious source for the world, using pigging process, more water is saved. So, the pigging process is eco-friendly.

FAQ About Pigging Process

Hyperfore Pigging Systems Types

Hyperfore Pipeline Pigging Solutions

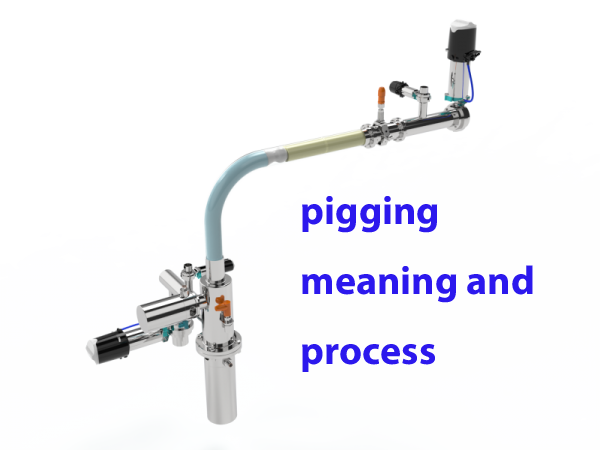

What Components Does a Pigging System Consist of?

A pigging system normally consist of several parts, including a launching station, a receiving station, stopping station, one pig or two pigs, and piggable products.

Launching Station

Also called the launcher, it is used to contain the pig and also the place where the pig is launched like a projectile into the pipe to do the pigging task. Hyperfore launcher is made of stainless steel 316L with cavity structure, it can contact the food product and other similar medium without causing pollution. It is normally installed vertically, and it is usually installed after the outlet of the pump.

Receiving Station

Hyperfore receiving station is made of SS316L, a kind of material that can be in direct contact with the food and pharmaceuticals product. The receiving station is a device that can capture the pig when it finishes the pigging process. It is normally installed before the destination tank or filling machine. And from the receiver, the pig can return to the launcher again.

Stopping Station

Same as the literal meaning, Hyperfore stopping station is to stop the pig when it finishes the pigging task. The receiver and the stopping station is different. When the pig arrives at the receiver, it can’t go forward any more. But, when the pig arrives at the stopping station, it can either stop, or move forward to the next destination. Hyperfore stopping stations are normally installed along the main pigging pipeline, where there are several tanks on the bypass pipelines,so that the product can be recovered to each individual tank accordingly.

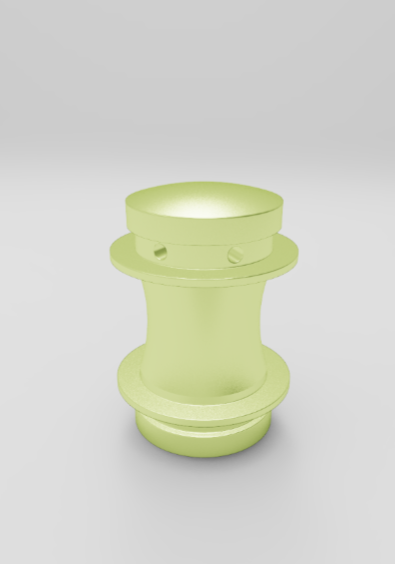

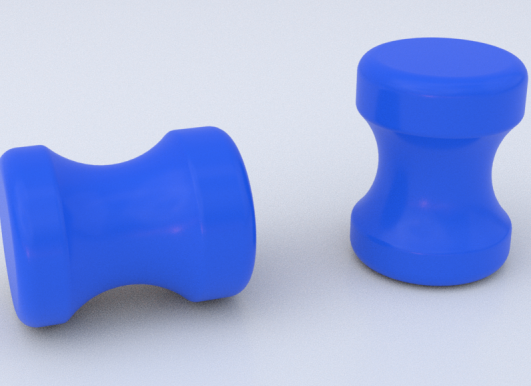

Pig or Scraper

The pipeline pigs are most important components of the pigging system. Hyperfore sanitary pig is a small elastic projectile made of food grade material, like VMQ, EPDM, FKM, etc. We have several kinds of pigs, such as one-piece pig and lip-pig, applicable to different products and industries.

Pig Speed Controller

It is very important for the pig (Hyperfore pig is bi-directional pigs.)to be running at an even speed along the pipe. If the pig speed is too fast, it may hit on the gear lever of the receiving station or some point of the pipe wall, and cause self-damage. Hyperfore pig speed controller is designed to control the pig speed by regulating the air pressure or air flow volume that drives the pig to move in the pipeline.

PLC and Electrical Panel

For an automated pigging system, the system is controlled by automation software and HMI, so the PLC system and electrical control cabinet are necessary.

Piggable Products

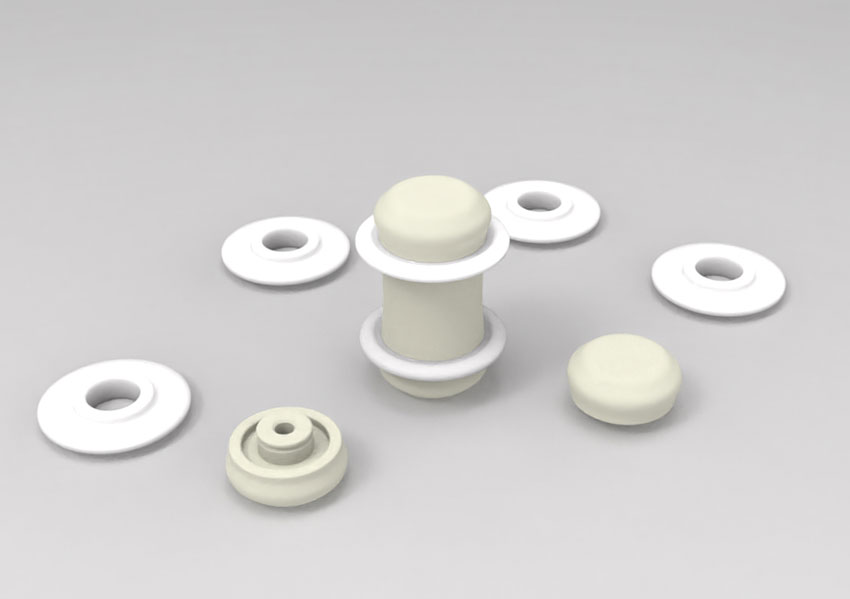

These piggable products include the piggable Tee, piggable elbows, piggable clamp, piggable flange and so on.

Pigging System Case Study

Every month, saving several hundreds of kilograms of product, including sauce, oil, shampoo, chemicals and so on.

Hello, customers

My name is Richard Gan, I am the general manager of Beijing Hyperfore Technology Company Ltd..Our Company was founded in 2005, and we have been engaged in sanitary pigging system and solutions for almost 10 years in China.

If you have any questions, please feel free to contact us. We are pleased to provide you best products and services.

Email: wenbo.gan@hyperfore.cn WeChat: hyperfore2005

WhatsApp: +86 18911747459