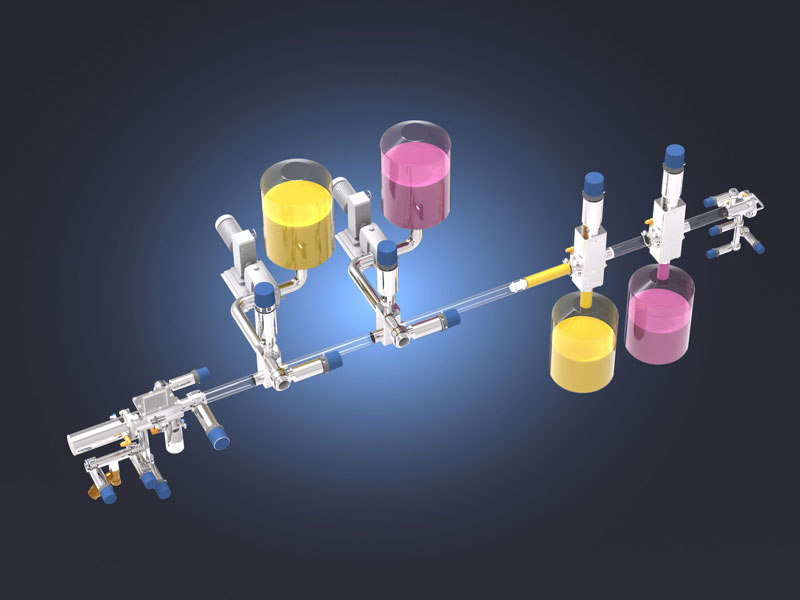

Hyperfore Micro-Residue Pigging System: Optimal Product Recovery and Efficiency

Hyperfore micro-residue pigging system is engineered to achieve a product recovery rate of up to 99.5%. By reducing pipeline residue level to just a few grams per meter, it ensures maximum product purity and effectively preventing cross-contamination.

Micro-Residue VS. Low-Residue Pigging System

Low-residue pigging system and micro-residue pigging system are different primarily in their components and the degree of residue reduction achieved. Users can flexibly combine components to configure different systems tailored to the production requirements. They are both good choices for pigging sensitive products that utilized a shared pipeline, including paints, solvent-based coatings, resins, colorants, special chemicals, adhesives. Micro-residue pigging system is specially designed for minimizing the residue product amount in the pipeline, it utilizes a more sophisticated configuration of launchers, receivers, 3-way diverter valves to minimized pipeline residue, protecting product purity and achieving zero cross-contamination. While low- residue pigging system is constructed for reducing the residue product amount in the pipeline, it offers a cost-effective alternative for standard pigging requirements.Micro-Residue Pigging System advantages

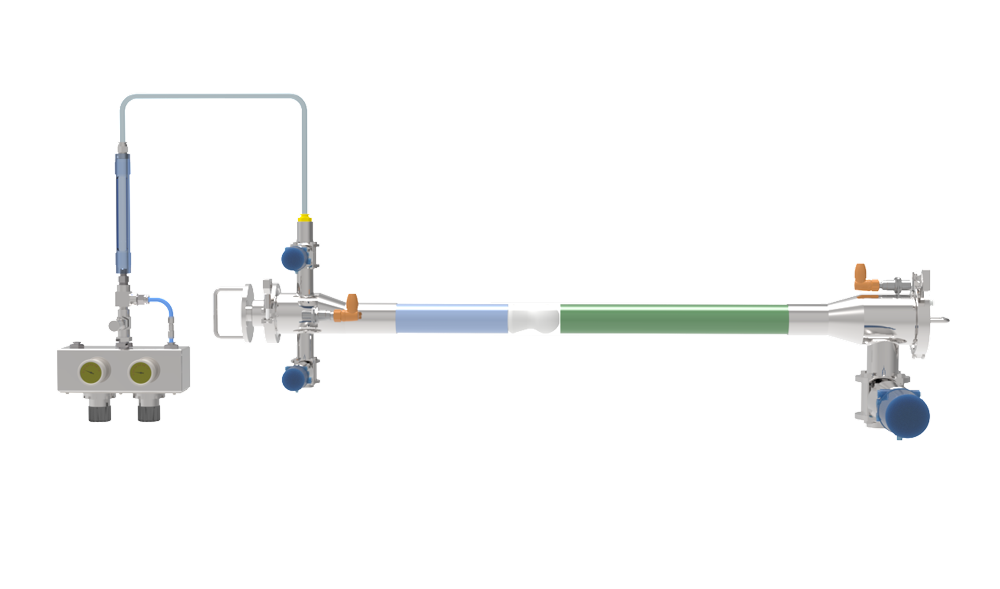

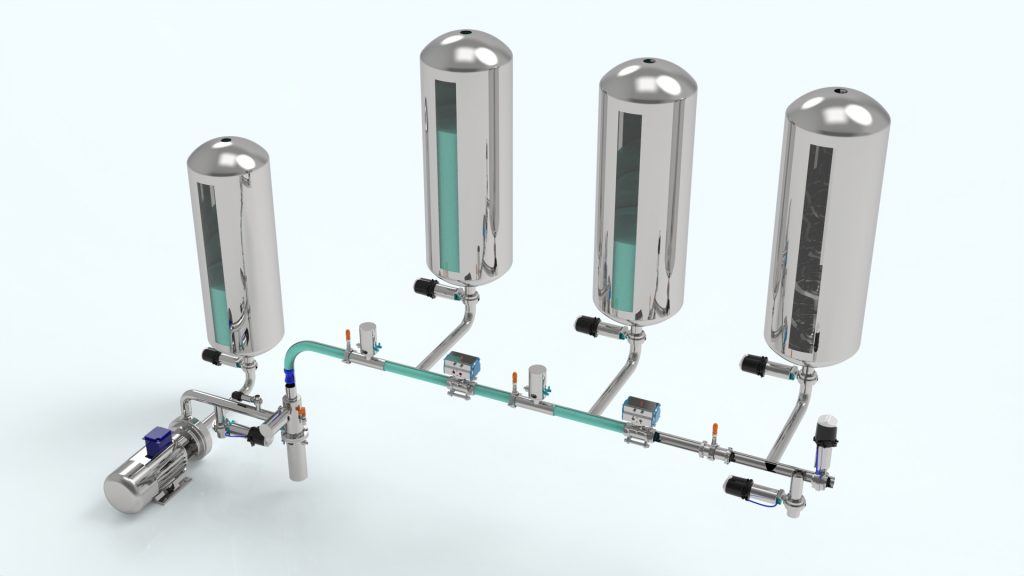

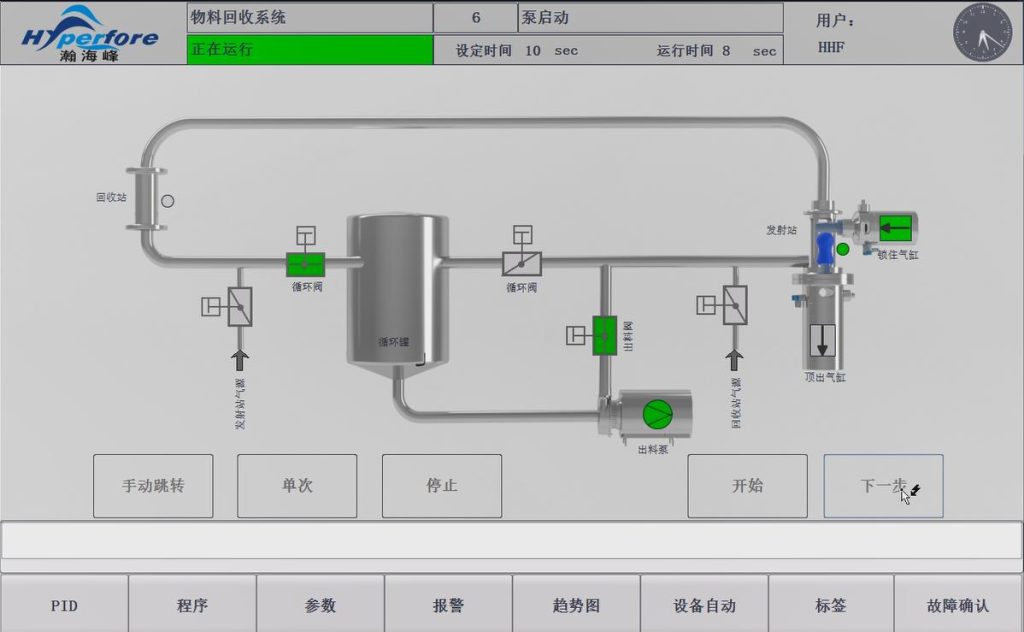

Micro-Residue Pigging System Technical Details and Components

Introduction

Micro-residue pigging system specifications

| Item | Parameter |

|---|---|

| DIN11850 | DN25,DN40,DN50,DN65,DN80,DN100,DN125,DN150 |

| ISO | 1”,1.5”,2”,2.5”,3”,3.5”,4”,5”,6” |

| Material | SS316L for parts contacting products, SS304 for other parts |

| Pressure | 0-1.6MPa |

| Polishing | Ra≤0.8μm (for product-contacting surfaces) |

| Temperature | ≤100°C |

| Sealing | EPDM, FKM, VMQ |

| Pig driving Pressure | less than or equal 0.6MPa |

| Application | Paints, coatings, chemicals and others |

Features

Features

Micro‐residue launcher‐ DIN Series

| Part No. | Size | OD*T |

|---|---|---|

| DHDFFBAD025A | DN25 | Φ29*1.5 |

| DHDFFBAD040A | DN40 | Φ41*1.5 |

| DHDFFBAD050A | DN50 | Φ53*1.5 |

| DHDFFBAD065A | DN65 | Φ70*2.0 |

| DHDFFBAD080A | DN80 | Φ85*2.0 |

| DHDFFBAD100A | DN100 | Φ104*2.0 |

| DHDFFBAD125A | DN125 | Φ129*2.0 |

| DHDFFBAD150A | DN150 | Φ154*2.0 |

Micro‐residue launcher‐ ISO Series

| Part No. | Size | OD*T |

|---|---|---|

| DHDFFBAT025A | 1" | Φ25.4*1.5 |

| DHDFFBAT038A | 1.5" | Φ38.1*1.5 |

| DHDFFBAT051A | 2" | Φ50.8*1.5 |

| DHDFFBAT064A | 2.5" | Φ63.5*2.0 |

| DHDFFBAT076A | 3" | Φ76.1*2.0 |

| DHDFFBAT089A | 3.5" | Φ88.9*2.0 |

| DHDFFBAT102A | 4" | Φ101.6*2.0 |

| DHDFFBAT127A | 5" | Φ127.0*2.0 |

| DHDFFBAT152A | 6" | Φ152.4*2.0 |

Micro‐residue receiver‐ DIN Series

| Part No. | Size | OD*T |

|---|---|---|

| DHDHFBAD025A | DN25 | Φ29*1.5 |

| DHDHFBAD040A | DN40 | Φ41*1.5 |

| DHDHFBAD050A | DN50 | Φ53*1.5 |

| DHDHFBAD065A | DN65 | Φ70*2.0 |

| DHDHFBAD080A | DN80 | Φ85*2.0 |

| DHDHFBAD100A | DN100 | Φ104*2.0 |

| DHDHFBAD125A | DN125 | Φ129*2.0 |

| DHDHFBAD150A | DN150 | Φ154*2.0 |

Micro‐residue receiver‐ ISO Series

| Part No. | Size | OD*T |

|---|---|---|

| DHDHFBAT025A | 1" | Φ25.4*1.5 |

| DHDHFBAT038A | 1.5" | Φ38.1*1.5 |

| DHDHFBAT064A | 2" | Φ50.8*1.5 |

| DHDHFBAT064A | 2.5" | Φ63.5*2.0 |

| DHDHFBAT076A | 3" | Φ76.1*2.0 |

| DHDHFBAT089A | 3.5" | Φ88.9*2.0 |

| DHDHFBAT102A | 4" | Φ101.6*2.0 |

| DHDHFBAT127A | 5" | Φ127.0*2.0 |

| DHDHFBAT152A | 6" | Φ152.4*2.0 |

What Products Is This System For?

Related Products

Related Articles

Ready to Maximize Your Recovery?

Have questions about micro-residue pigging systems? Use the form to contact us, our senior engineers will offer a custom solutions.

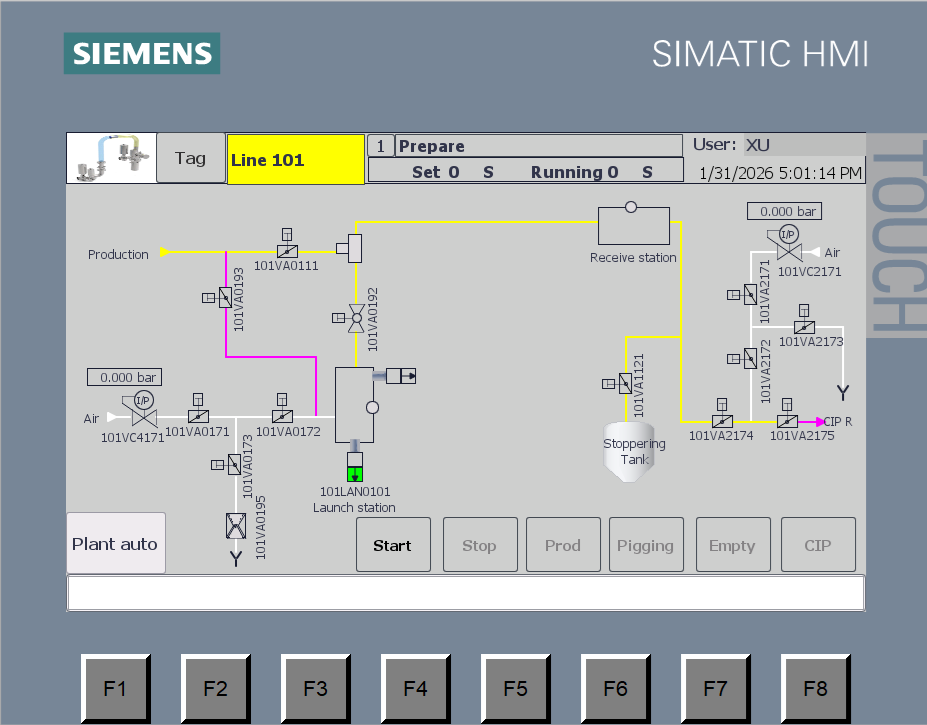

.16-1024x768.jpg)

.3-1024x684.png)

.2.jpg)