High-Efficiency Manual Pigging System with Fast ROI

Key features:engineered for highefficiency

High Recovery Rate

Over 99% of the valuable residue products can be recovered

Rapid ROI

The investment can be retrieved within as little as 3-6 months for most applications

Sanitary Design

Manual pigging system is engineered for hygienic pigging process

Ultra-Low Retention

Almost zero liquid residue in the manual stations after pigging operation

CIP Compatible

Manual pigging system is compatible with CIP system(clean in place)

Custom Solution

Fully manual or semi-manual pigging solutions can be tailored upon request

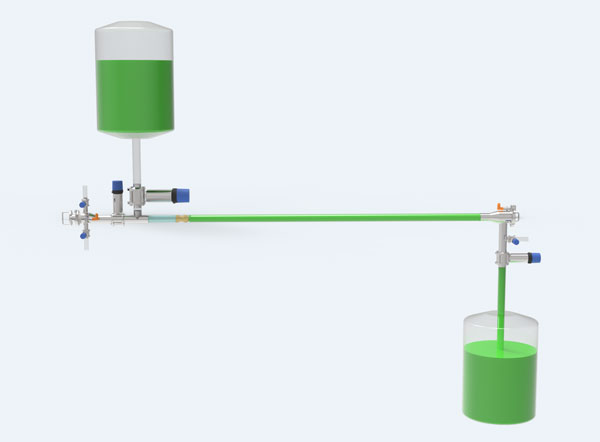

Cost-Effective Solutions With Manual Pigging System

Save 99% Residue Product and Slash Sewage Treatment Expenses with Our Manual Pigging System

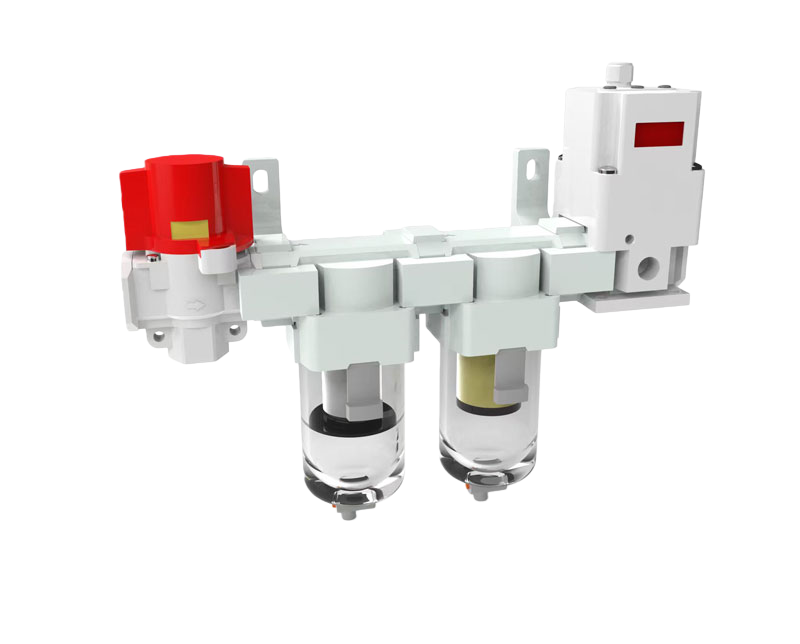

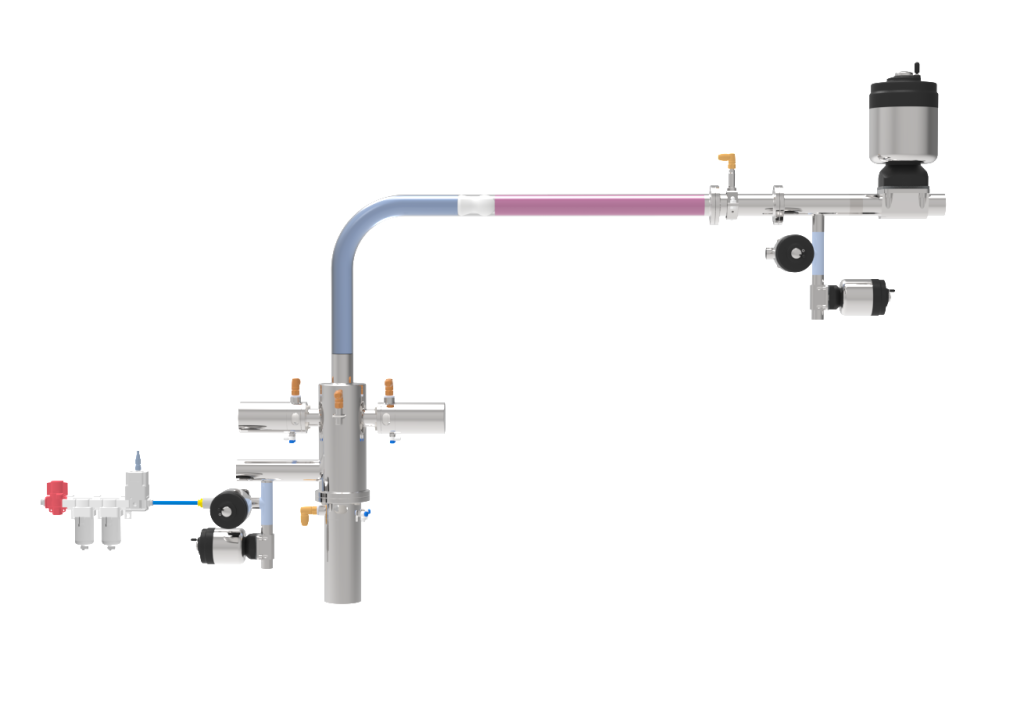

HYPERFORE manual pigging system is an economical and hygienic pipeline product recovery equipment. The core components includes a manual launcher, a manual receiver and a pig. The system is specifically constructed for food, household liquids, cosmetics, personal care products and pet food industries. Given the fast payback period and high cost-efficiency, the manual pigging system is ideal for manual or semi-manual production lines, or liquid transfer processes where pigging operation is not required on a frequent basis.

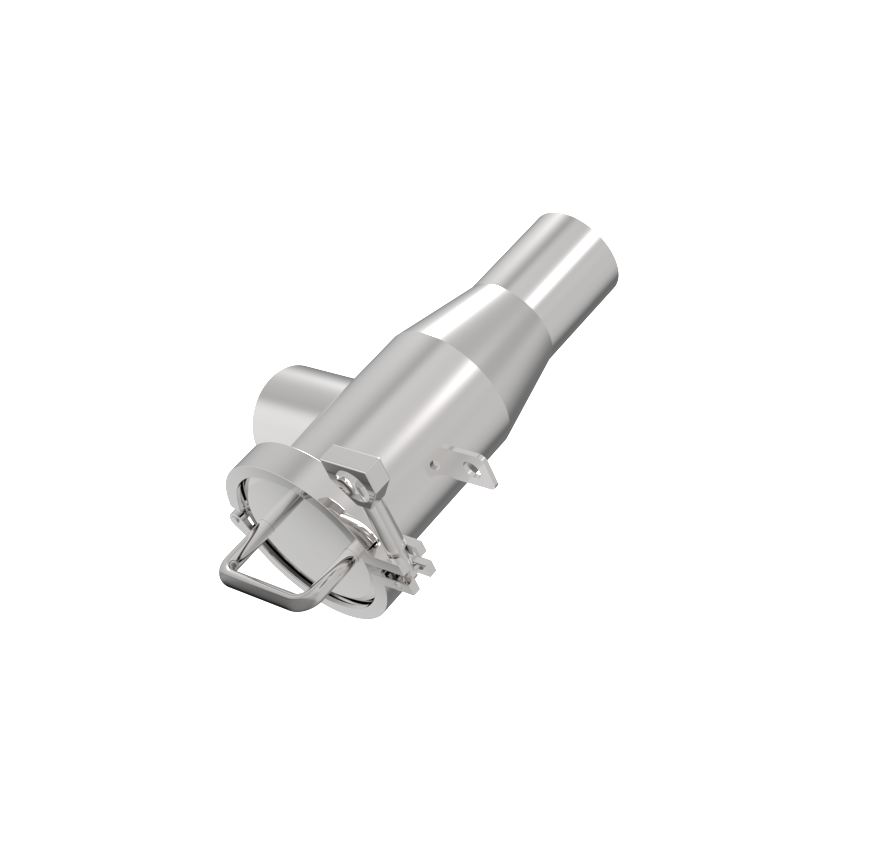

Manual launcher introduction

A manual pig launcher is a device designed to introduce a pig into the pipeline, so that the pig can move forward along the pipes to execute pigging operations, such as pipeline cleaning and residual product recovery. The launcher can also function as a housing for the pig, where it can be cleaned as part of the overall the pigging system.

Features:

Technical Specifications

Manual Launcher-DIN Pipe

| PART NR. | SIZE | OD*T | |

| DMSSKBAD025A | DN25 | Φ29*1.5 | |

| DMSSKBAD040A | DN40 | Φ41*1.5 | |

| DMSSKBAD050A | DN50 | Φ53*1.5 | |

| DMSSKBAD065A | DN65 | Φ70*2.0 | |

| DMSSKBAD080A | DN80 | Φ85*2.0 | |

| DMSSKBAD100A | DN100 | Φ104*2.0 | |

| DMSSKBAD125A | DN125 | Φ129*2.0 | |

| DMSSKBAD150A | DN150 | Φ154*2.0 |

Manual Launcher-ISO Pipe

| PART NR. | SIZE | OD*T | |

| DMSSKBAT025A | 1″ | Φ25.4*1.5 | |

| DMSSKBAT032A | 1.25″ | Φ31.8*1.5 | |

| DMSSKBAT038A | 1.5″ | Φ38.1*1.5 | |

| DMSSKBAT051A | 2″ | Φ50.8*1.5 | |

| DMSSKBAT064A | 2.5″ | Φ63.5*2.0 | |

| DMSSKBAT076A | 3″ | Φ76.1*2.0 | |

| DMSSKBAT089A | 3.5″ | Φ88.9*2.0 | |

| DMSSKBAT102A | 4″ | Φ101.6*2.0 | |

| DMSSKBAT127A | 5″ | Φ127.0*2.0 | |

| DMSSKBAT152A | 6″ | Φ152.4*2.0 |

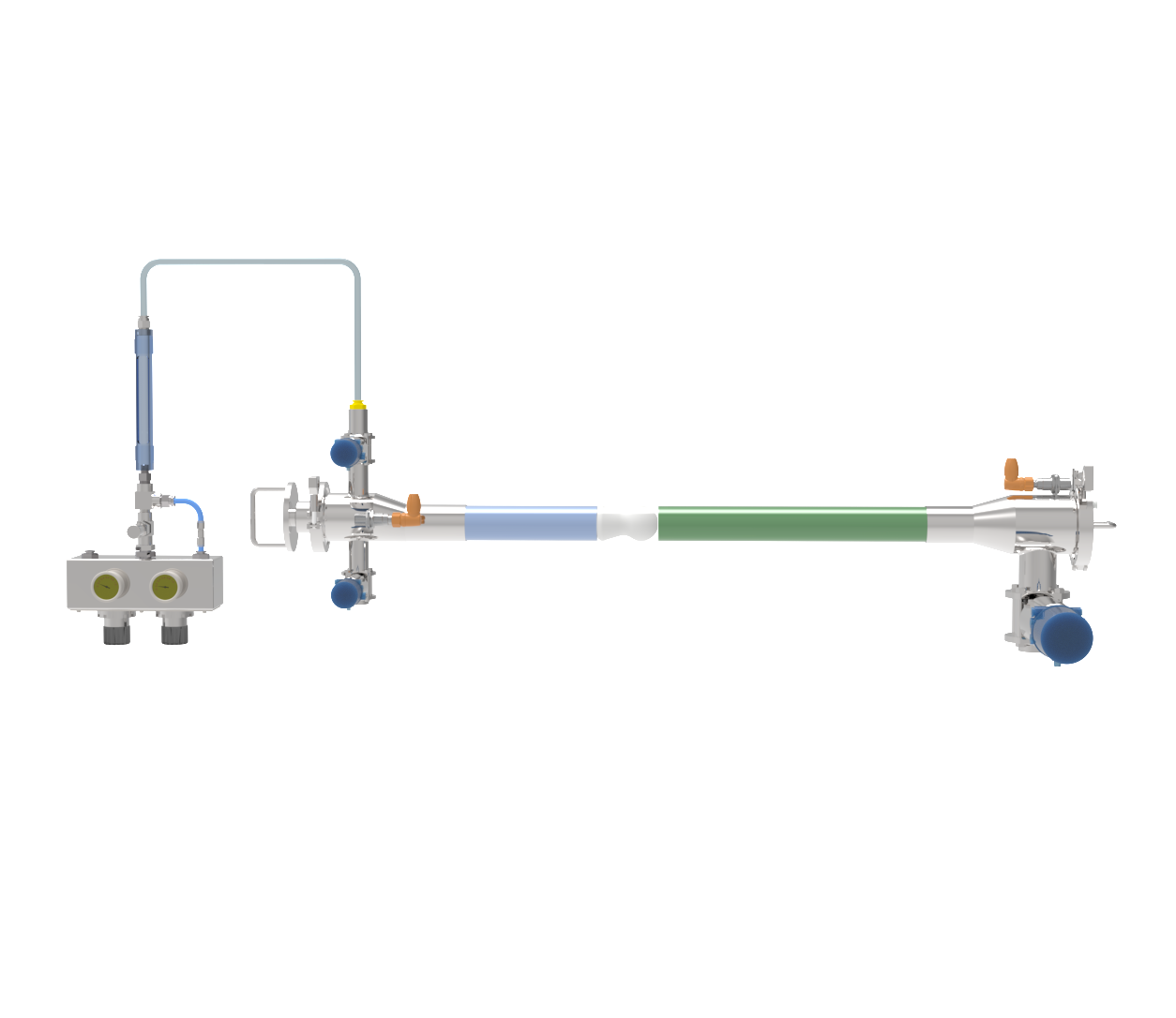

Manual Receiver introduction

A pig receiver is a device to intercept and secure a pig once it has completed its operation. Its primary functions are to stop the pig when it has cleaned the pipe and recovered residual products, or to provide an access point from where the pig is removed from the line without interrupting the fluid product transportation.

Features:

Technical Specifications

Manual Receiver Type A-DIN Pipe

| PART NR. | SIZE | OD*T |

| DMRSKBAD025A | DN25 | Φ29*1.5 |

| DMRSKBAD040A | DN40 | Φ41*1.5 |

| DMRSKBAD050A | DN50 | Φ53*1.5 |

| DMRSKBAD065A | DN65 | Φ70*2.0 |

| DMRSKBAD080A | DN80 | Φ85*2.0 |

| DMRSKBAD100A | DN100 | Φ104*2.0 |

| DMRSKBAD125A | DN125 | Φ129*2.0 |

| DMRSKBAD150A | DN150 | Φ154*2.0 |

Manual Receiver Type A-ISO Pipe

| PART NR. | SIZE | OD*T |

| DMRSKBAT025A | 1″ | Φ25.4*1.5 |

| DMRSKBAT032A | 1.25″ | Φ31.8*1.5 |

| DMRSKBAT038A | 1.5″ | Φ38.1*1.5 |

| DMRSKBAT051A | 2″ | Φ50.8*1.5 |

| DMRSKBAT064A | 2.5″ | Φ63.5*2.0 |

| DMRSKBAT076A | 3″ | Φ76.1*2.0 |

| DMRSKBAT089A | 3.5″ | Φ88.9*2.0 |

| DMRSKBAT102A | 4″ | Φ101.6*2.0 |

| DMRSKBAT127A | 5″ | Φ127.0*2.0 |

| DMRSKBAT152A | 6″ | Φ152.4*2.0 |

Manual Receiver Type B-DIN Pipe

| PART NR. | SIZE | OD*T |

| DMRSKBAD025B | DN25 | Φ29*1.5 |

| DMRSKBAD040B | DN40 | Φ41*1.5 |

| DMRSKBAD050B | DN50 | Φ53*1.5 |

| DMRSKBAD065B | DN65 | Φ70*2.0 |

| DMRSKBAD080B | DN80 | Φ85*2.0 |

| DMRSKBAD100B | DN100 | Φ104*2.0 |

| DMRSKBAD125B | DN125 | Φ129*2.0 |

| DMRSKBAD150B | DN150 | Φ154*2.0 |

Manual Receiver Type B-ISO Pipe

| PART NR. | SIZE | OD*T |

| DMRSKBAT025B | 1″ | Φ25.4*1.5 |

| DMRSKBAT032B | 1.25″ | Φ31.8*1.5 |

| DMRSKBAT038B | 1.5″ | Φ38.1*1.5 |

| DMRSKBAT051B | 2″ | Φ50.8*1.5 |

| DMRSKBAT064B | 2.5″ | Φ63.5*2.0 |

| DMRSKBAT076B | 3″ | Φ76.1*2.0 |

| DMRSKBAT089B | 3.5″ | Φ88.9*2.0 |

| DMRSKBAT102B | 4″ | Φ101.6*2.0 |

| DMRSKBAT127B | 5″ | Φ127.0*2.0 |

| DMRSKBAT152B | 6″ | Φ152.4*2.0 |

Try Our Calculator: Estimate Your Payback Period and Potential Savings

Investment Recovery Calculator

Calculate Your Personalized Payback Period Based on Your Specific Data

Related Products

Case Studies

Frequently Asked Questions

Contact us with your pipe diameter and product type for a custom quote!