Automatic Sanitary Pigging System for Efficient Product Recovery

Achieving 99%+ product recovery for food and pharma pipelines

Hyperfore automatic sanitary pigging system offers an effective solution for food, pharmaceutical manufacturers who are struggling with product waste, high production cost, low efficiency, cross-contamination.

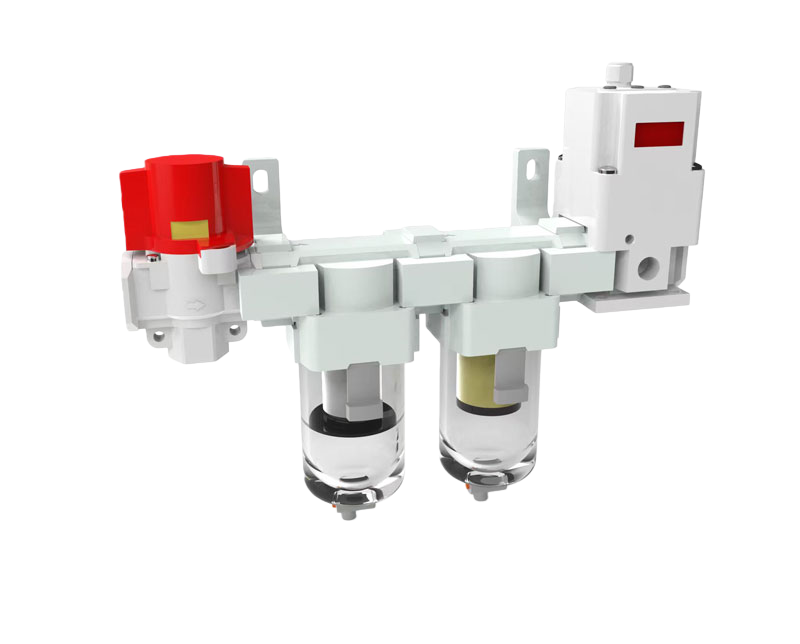

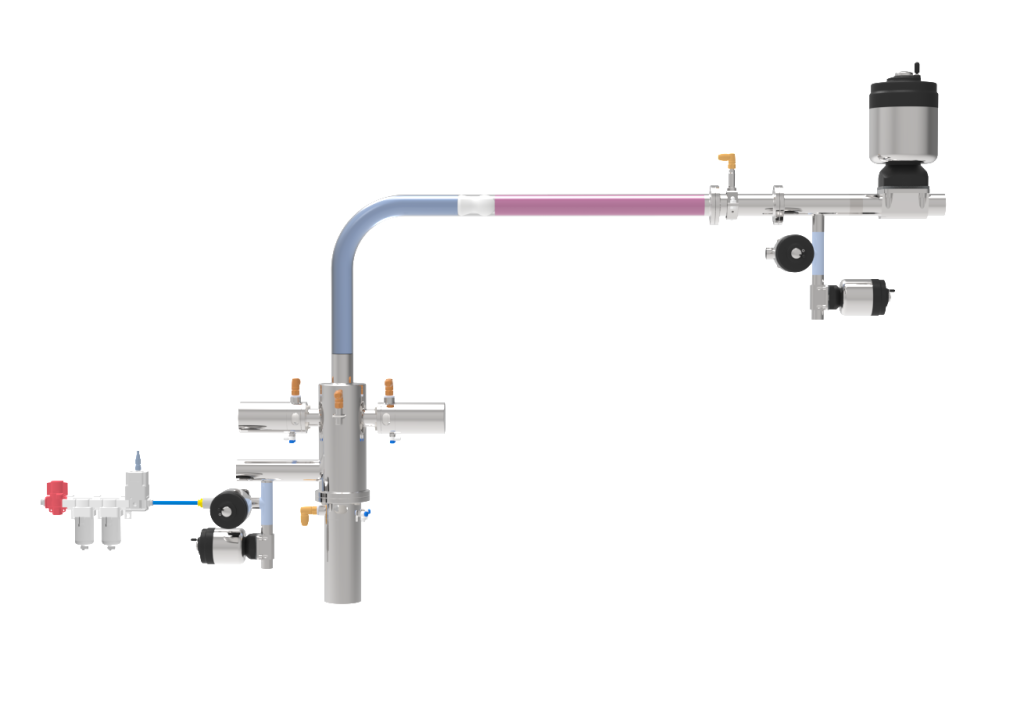

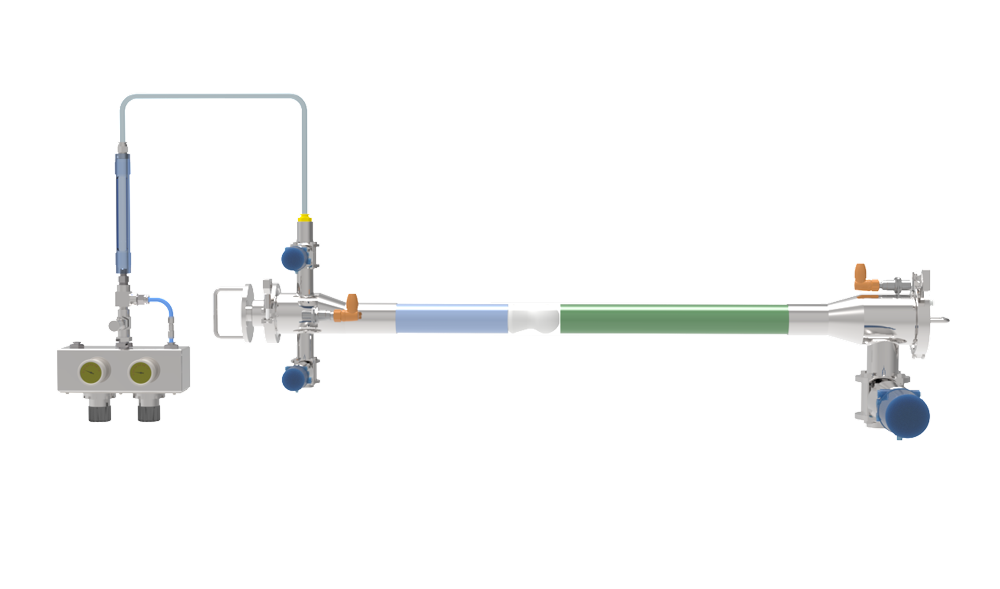

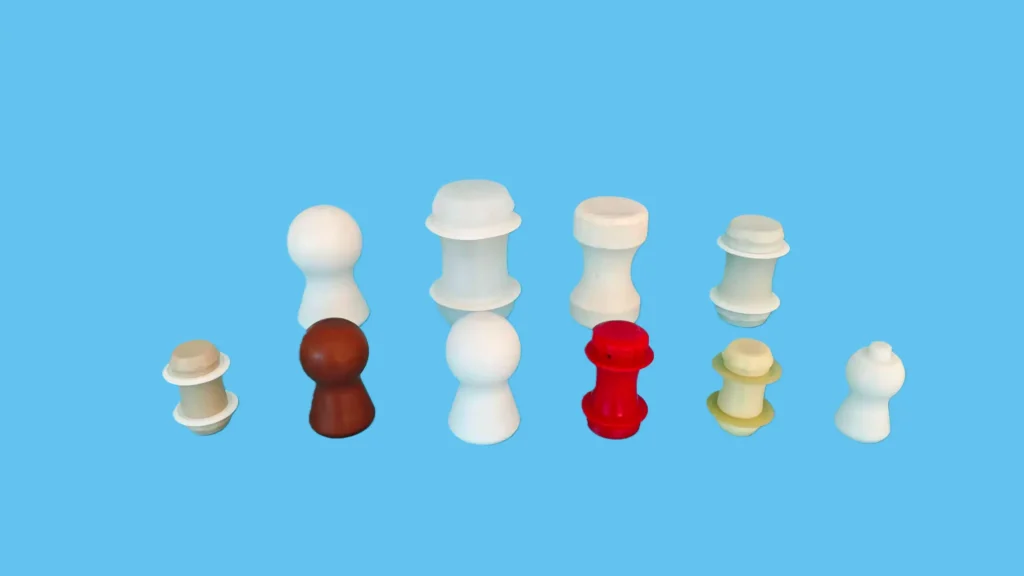

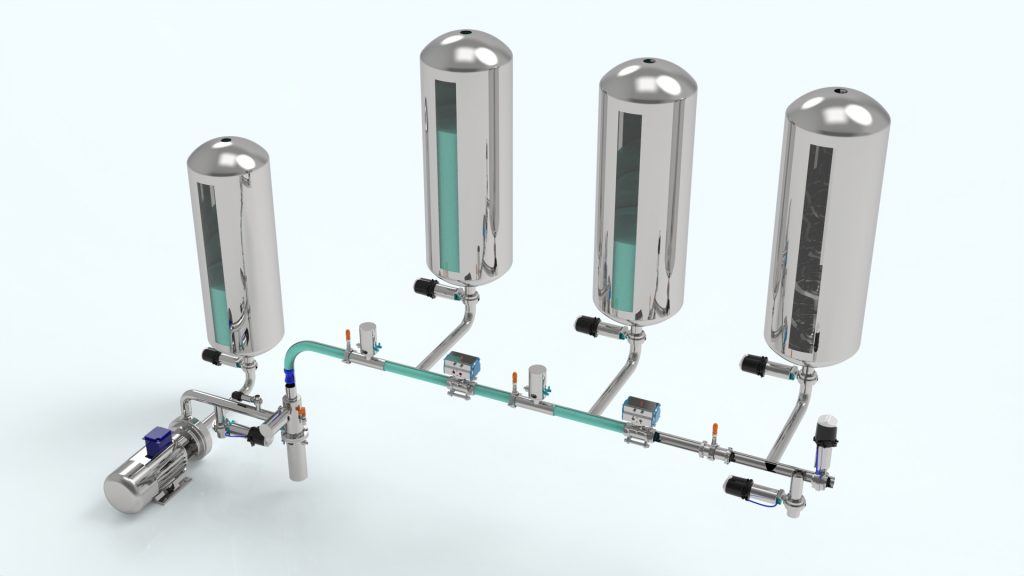

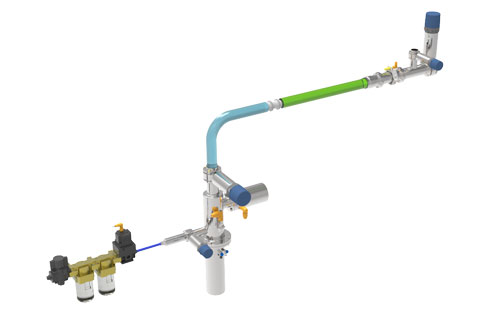

Components

Hyperfore sanitary pigging system includes launching station, pigs(scrapers), pig stopper, receiving station and other components.

Benefits

Sanitary pigging systems help to improve yields, save large amount of water, cleaning agents and reduce the time for CIP.

Efficiency

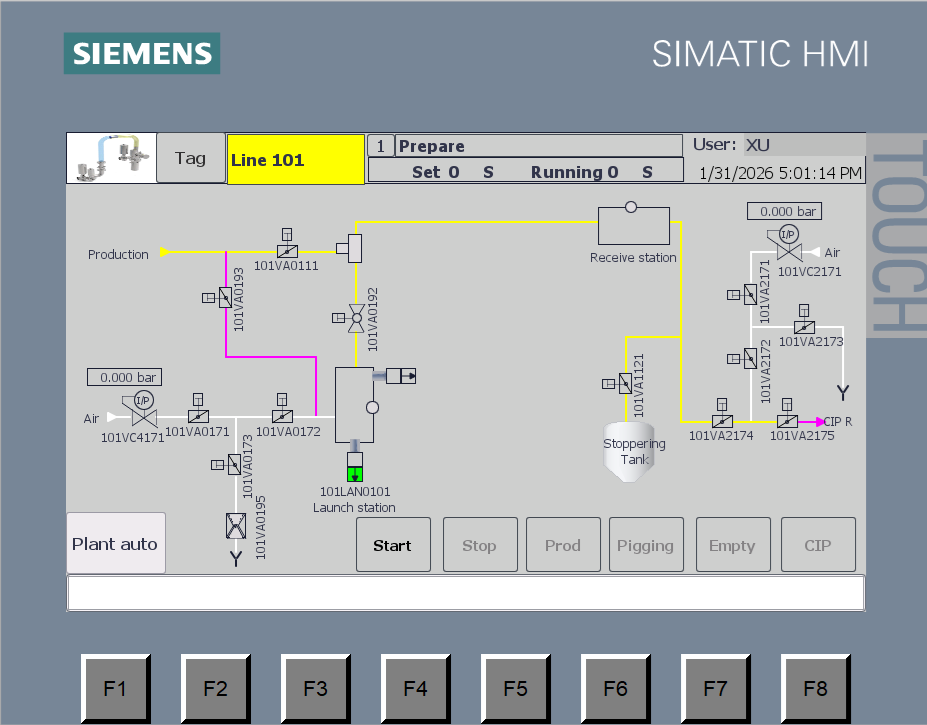

Hyperfore sanitary pigging system is automatic, it can recover more than 99.5% of the valuable liquid product remained in the pipes, largely shorten pipe cleaning time.

Applications

Hyperfore pigging systems are widely used in liquid food products, pharma, cosmetics, pet food, personal care and household, curry sauce industries, and more.

Minimizing Product Loss for Food and Pharma Production

Hyperfore Sanitary Pigging System

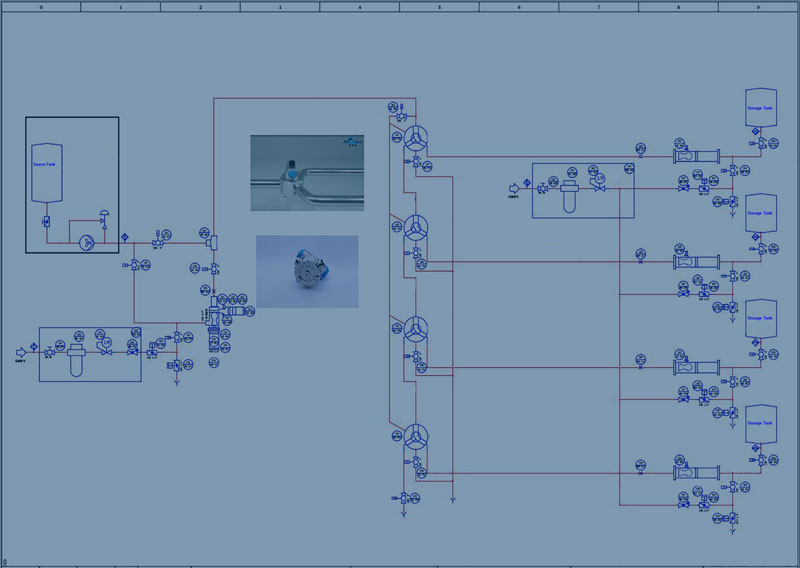

The primary components of Hyperfore sanitary pigging system include: a pig launcher, a receiver, a pig, pig detection unit, pig speed controller, piggable valves. It can significantly improve production, reduce waste and cross contamination. The sanitary pigging system is engineered to achieve a product recovery rate exceeding 99%, significantly reduce product waste and CIP cost. Ideal for: Food, dairy, alcohol, liquid pharma, personal care products and cosmetics. Control mode: Automatic Hygiene level: Food and pharma compliant| Item | Parameter |

|---|---|

| DIN11850 | DN25,DN40,DN50,DN65,DN80,DN100,DN125,DN150 |

| ISO | 1”, 1.25”, 1.5”, 2”, 2.5”, 3”, 3.5”, 4”, 5”, 6” |

| Material | SS304, SS316L for product-contact surfaces |

| Pressure | ≤10bar |

| Polishing | Ra ≤ 0.8μm (product-contact surfaces) |

| Temperature | ≤ 121°C |

| CIP/SIP | Compatible |

| Sealing | EPDM, other materials customizable upon request |

Sanitary Pigging System Cases

Related Products

Pigging System Turnkey Engineering Services

Frequently Asked Questions

Request a Custom ROI Calculation

Use the form to reach out, we will get in touch with you as quickly as possible.