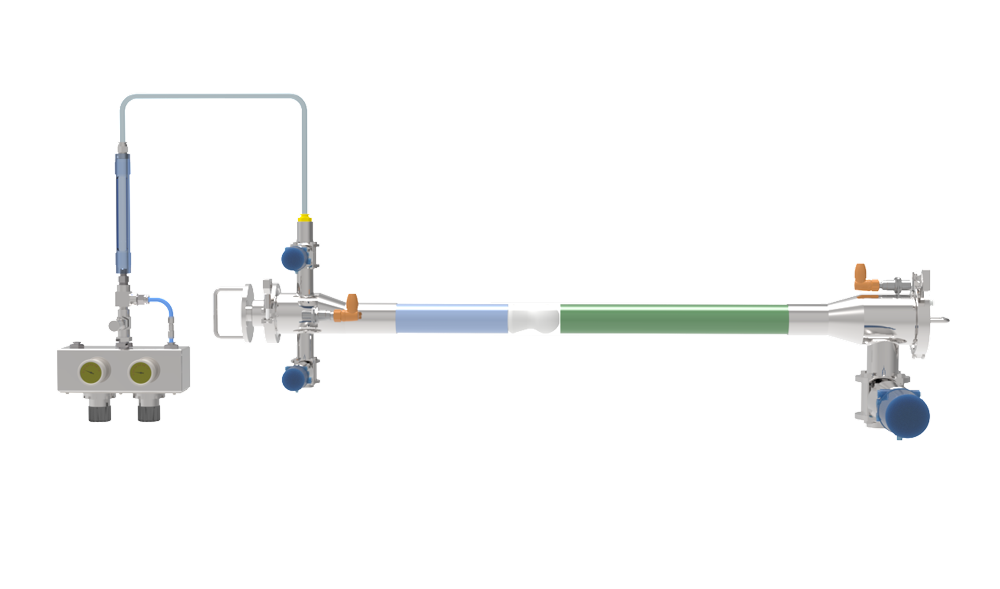

Hyperfore Turnkey Pigging Automation Solutions:

From Design To Commissioning

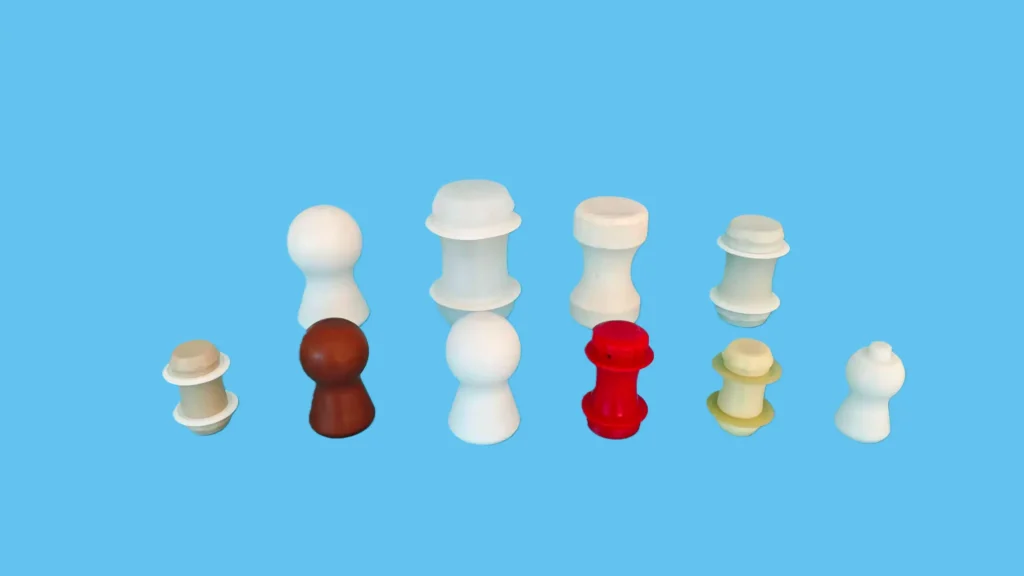

HYPERFORE is an expert in delivering turnkey pigging automation solutions across a diverse range of industries. We have decades of experience in electrical and automation engineering in liquid processing, specializing in Siemens PLC programming, custom electrical design, cabinet manufacturing, and global remote support to maximize your product recovery.

Precision PLC Logic Development

To achieve superior control over automated pigging process, HYPERFORE developed industrial automation solution platform software Iplant IT. This robust platform software can be applied not only to standalone pigging systems, but also to whole plant automation solutions. Beyond software, HYPERFORE also implemented comprehensive turnkey automation and electrical engineering services, ensuring seamless integration of automation systems to existing systems.

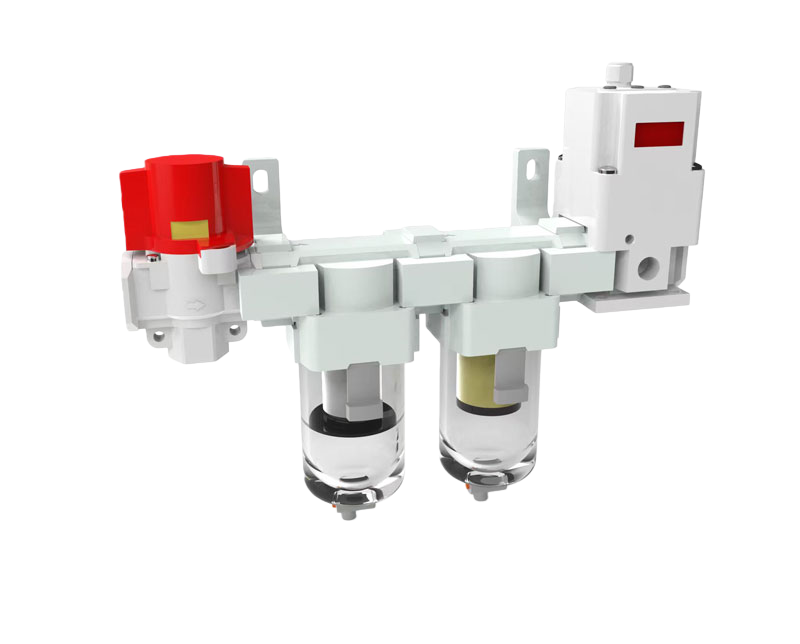

Custom Electrical Design & Panel Fabrication

In cabinet design, building and factory testing, we strive to minimize the possibility of failure. Through a series of management methodologies, we have improved the rationality and accuracy of our design and building processes, ensuring that our electrical cabinets are safe and stable upon delivery.

We deliver high-quality electrical control cabinets manufactured to rigorous international standards, including IP65 and IEC. Utilizing specialized design software for standardized, precise design, HYPERFORE ensures that every panel is built for durability. Our hardware solutions provide a solid foundation for your automated pigging pipelines.

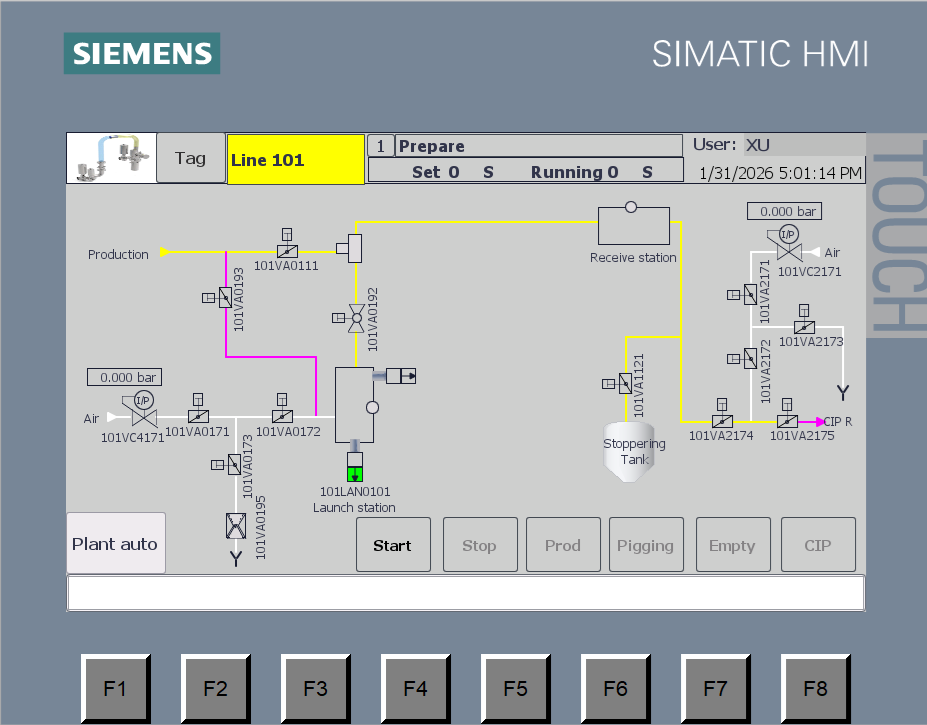

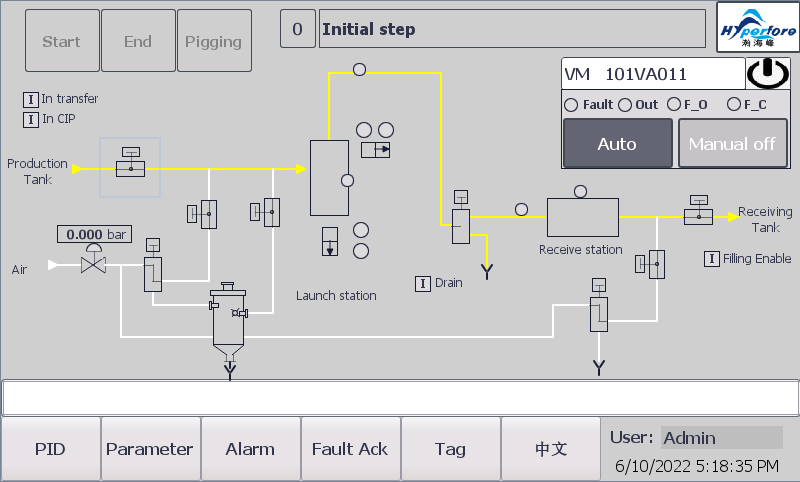

At HYPERFORE, we believe the automation program is only as good as its interface. We developed intuitive HMI/SCADA solutions tailored to your pigging process needs. By integrating the real-time data visualization, trend logging, and comprehensive alarm management, we believe that your team will be absolutely clear about the pig position, production status. And you can react rapidly at the very first moment an issue occurs, minimizing human errors and maximizing uptime.

On-site & Remote Commissioning

Precision in commissioning is the guarantee of the system performance. HYPERFORE provides on-site and remote support, covering everything from process equipment installation inspection, IO testing, to dry testing, water testing, product testing, final check and acceptance.

Our systematic approach is to ensure the good coordination of every equipment and instrument in the system. Combining the expertise of our field engineers with diagnostic tools, we are confident to deliver you a trouble-free pipeline and optimized plant.

Trusted By Global Partners

For Our Turnkey Pigging Automation Solutions

Related Cases

Contact Us

Ready for a custom pigging automation design? Fill in the form to share your project requirements., we will offer you a professional feedback at the very first moment.