China Product Recovery( Pigging )Case Study : – HSINLKN

HSINLKN Used Pigging System To Recover Laundry Detergent

Case Study- China Huaian HSINLKN

How Hyperfore sanitary pigging system(product recovery system) help Chinese daily chemical products manufacturer improve yielding, reduce waste, and enhance efficiency and profit in mayonnaise production.

Summary

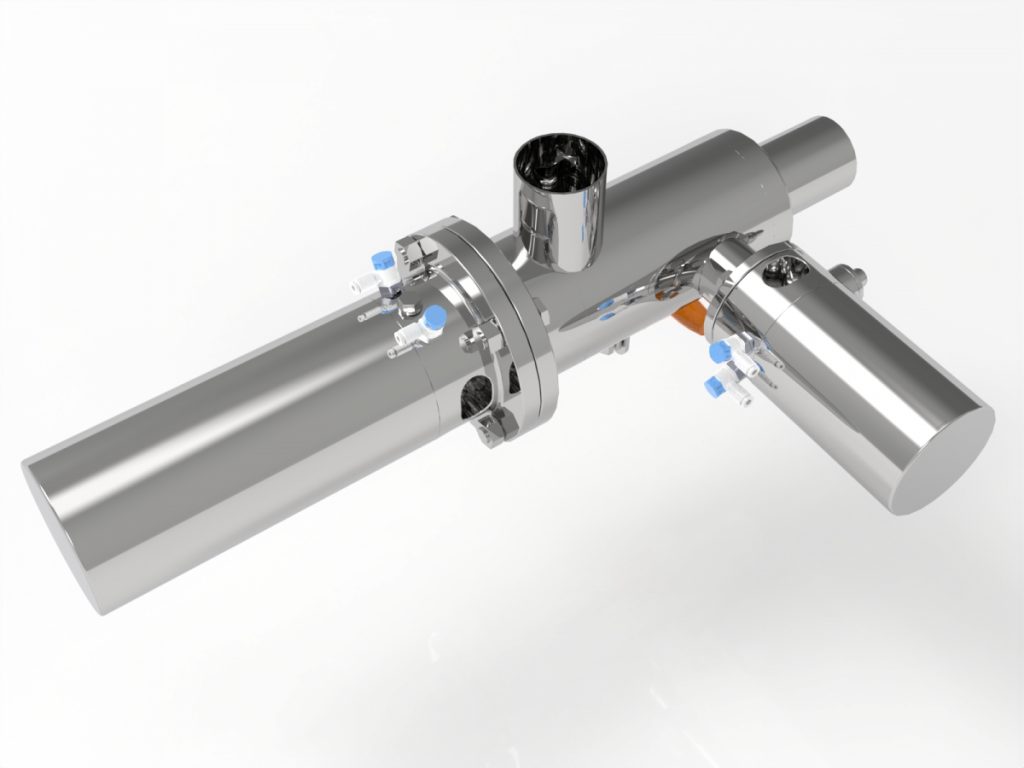

HSINLKN is a Chinese daily chemical products OEM that produces various household cleaning solutions for well-known brands like P&G,BaiMao, etc., products are shampoo, shower gel, laundry detergent, and more. To support their production line, they approached Hyperfore for a turnkey project that included two sets of 2-inch automated sanitary pigging systems, PLC control system, electrical control cabinet, installation service, commissioning service, and technical support and other pigging products .

HSINLKN’s decision to partner with Hyperfore for their detergent production lines was a wise one. Our turnkey project provided them with a robust and reliable solution that helped them to improve their operations and achieve their business goals more effectively. We are proud to have played a part in this success story and look forward to working with HSINLKN again in the future.

About China Huaian HSINLKN

China Huai’an HSINLKN is a daily chemical company with a registered capital of 180 million yuan. The company was established on December 8, 2016 in Huai’an City, Jiangsu Province. Its main business scope includes the production (only physical process), research and development, and sales of synthetic detergents, soaps, cosmetics, toothpaste, oral cleaning products, and other daily chemical products. Huai’an Xin Le Kang Daily Chemical Co., Ltd. is a large-scale and competitive daily chemical company with a wide range of business scope and strong R&D capabilities. The company has a good operating status and has certain technical strength and consulting services capabilities in the field of chemical technology. At the same time, the company also pays attention to the protection of intellectual property rights and owns several registered trademarks.

Hyperfore’s Solution: Upgrading Pipeline and Implementation Of an Pigging System

China Huai’an HSINLKN had previously installed pigging systems from another domestic brand. However, the customer felt that the price was a bit high and was concerned about the return on investment (ROI) of the pigging system. We informed them that Hyperfore’s ROI for pigging systems is typically quick, within 3-6 months. The biggest issue was related to engineering, as their previous design had some problems with the pipe size connecting the filling machine not being sufficient. As a result, the product speed was slow, and the filling machine always had to wait.

The customer approached us because they wanted to update their problematic old system and install a new automatic pigging system for cleaner pipelines. Each pipe was over 100 meters long and connected several source tanks, with a filling machine at the end of the line.

The Problems and How Hyperfore Solved Them

The biggest challenge was related to engineering, as their previous design had some problems with the pipe size connecting the filling machine not being sufficient, resulting in slow product speed and the filling machine always having to wait. However, the customer came to us seeking an upgrade, wanting to install new automatic pigging systems for cleaner pipelines. Each pipe was over 100 meters long and connected with several source tanks, with a filling machine at the end of the line. This project involved the installation of a pigging system for a cleaner project with multiple sources and one destination. To achieve this, we used a swing-bend to switch different source tanks and connect them with the main pipe. Hyperfore was responsible for the pigging automation , equipment, installation, and commissioning of the system. We designed and delivered a standalone electric control panel with HMI (human-machine interface), and an independent PLC program was connected to the customer’s system via Ethernet. All equipment, pipes, and fittings were properly installed, and the site was organized. The installation took around two weeks, and one week for site commissioning. The turnkey project was successful, and to this day, the customer’s production has been running very well. The pigging ROI was quick, normally within six months.

Customer Reviews

As end users, they often struggle with finding suitable suppliers, especially when it comes to engineering projects. It can be a time-consuming and tedious task to search for the right engineering company and equipment or product supplier. However, the price of a project or product cannot guarantee its quality. Instead, experience, professionalism, and successful case studies can provide assurance.

Hyperfore is highly experienced in implementing turnkey pigging solutions. Since our foundation in 2005, we have been providing comprehensive solutions and engineering services to the liquid food industry. Our clients come from various industries such as dairy, alcohol, pharmaceuticals, seasonings, sauces, household detergents, paints and coatings, among others. Our partners who have worked with us usually have a very positive impression of us. They describe our cooperation as pleasurable after enduring the laborious process of searching for the right supplier. Many of them become our returning customers and are willing to recommend Hyperfore to others. As a result, we have established a strong reputation in the industry.

“We regard Hyperfore as a reliable partner. They are professional, and their automation engineering and installation services are excellent. We would like to recommend them to our friends or partners,” said an equipment manager of Huai’an HSINLKN. Working with Hyperfore can provide significant advantages to people looking for reliable and professional partners in the engineering industry.

Are you considering to install hygienic pigging systems on your productions lines, do you want to save your products, please get in touch with us for detailed information.

Related Articles

Hyperfore have many pigging system cases, pigging solutions cases, such as pigging system for food, pigging system for lithium battery slurry, pigging system for pharmaceuticals, and so on.

Have questions about product recovery system roi? Or what is pigging? Or choose pigging system? Use the form to reach out and we will reply to you as quickly as possible.