HYPERFORE

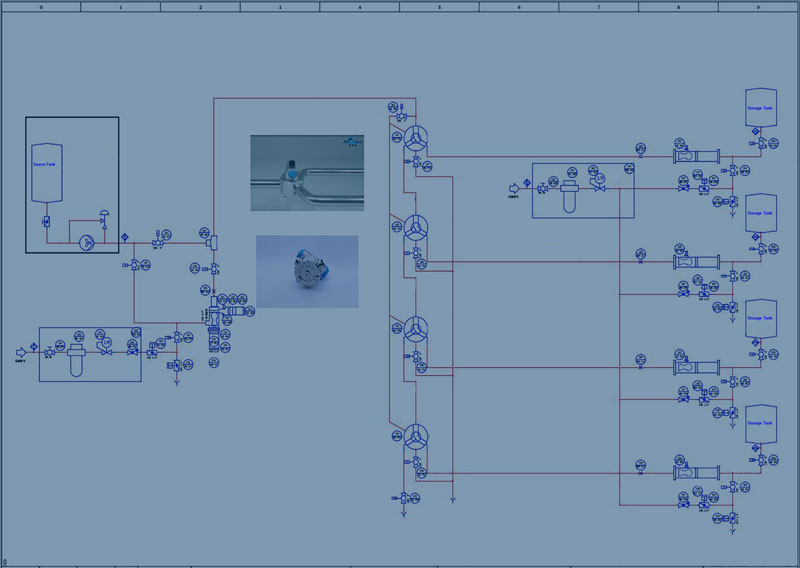

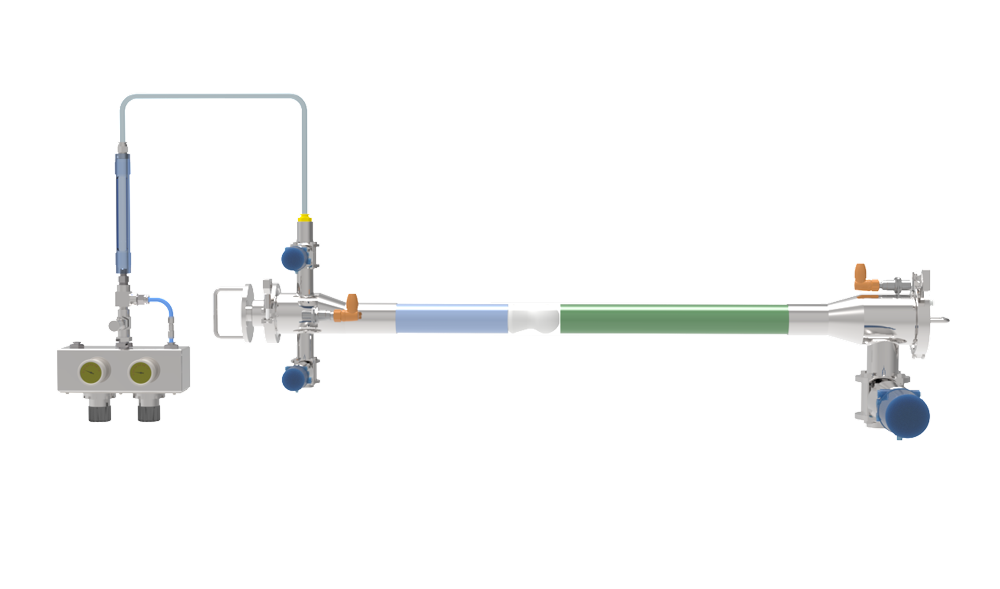

Turnkey Pigging System Installation

Hyperfore provides seamless integration of electrical and mechanical pigging installation strictly compliant with hygienic industrial standards. From on-site supervision to final acceptance testing, our team offer full-scale services to ensure the excellent operation of your plant.

For more than a decade, HYPERFORE has accumulated valuable experience in the field of installation and commissioning, especially for pigging installation. Our team has provided high-quality pigging system installation and commissioning services to leading brands manufacturers both home and abroad in many industries.

It is important to realize, professional engineering technique is very important, especially for the pigging system turnkey projects. HYPERFORE has a good command of the know-how for project implementation, and can avoid common problems from the very beginning. And we offer professional on-site supervision and management.

Electrical and Mechanical Installation

Engineering Management

- On-site Supervision: Our senior engineers provide professional supervision to ensure the working process strictly complies with P&ID, hygiene and safety protocols.

- Project Management: From quality to scheduling, our team ensures the pigging installation project is delivered on time and with high quality.

- Acceptance & Testing: Final delivery is only complete after our stringent Site Acceptance Test, we don’t leave after the installation, we stay until the system can perform to your standards.

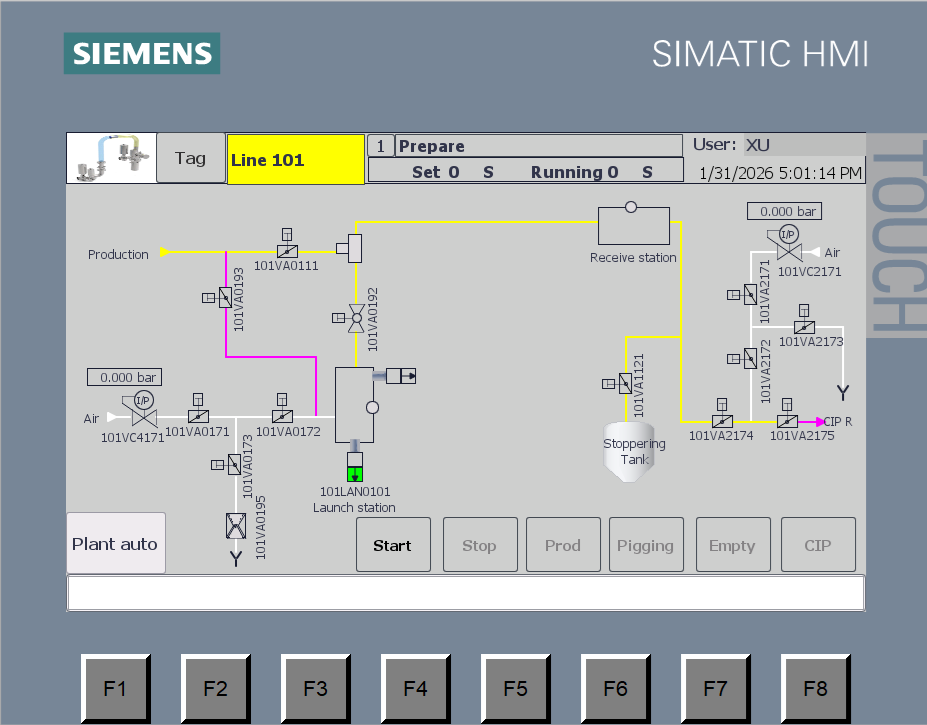

Remote Pigging Installation Guidance

We supply remote pigging installation guidance for global customers to ensure seamless electrical and mechanical integration. Utilizing real-time video meetings, our expert engineers guide your local team step by step, guaranteeing your system performs effectively and safely to your standards.

Related Cases

Pigging system cases of different industries are as below.

Dear partners

we Appreciate your PraiseHYPERFORE successfully delivered turnkey projects to the following partners

Frequently

Asked

Questions

Many of our customers have questions concerning the pigging system, automation control, and turnkey solutions. If you have similar questions ,please contact us.

Have questions about pigging system installation?Use the form to reach out and we will get in touch with you as soon as possible.