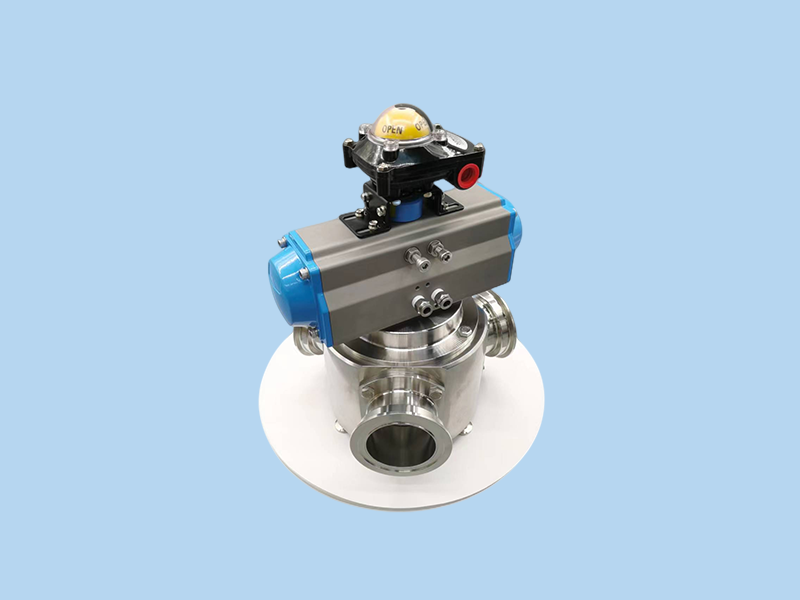

Piggable 3-Way Diverter Valve, 120° Sanitary Switch Solution

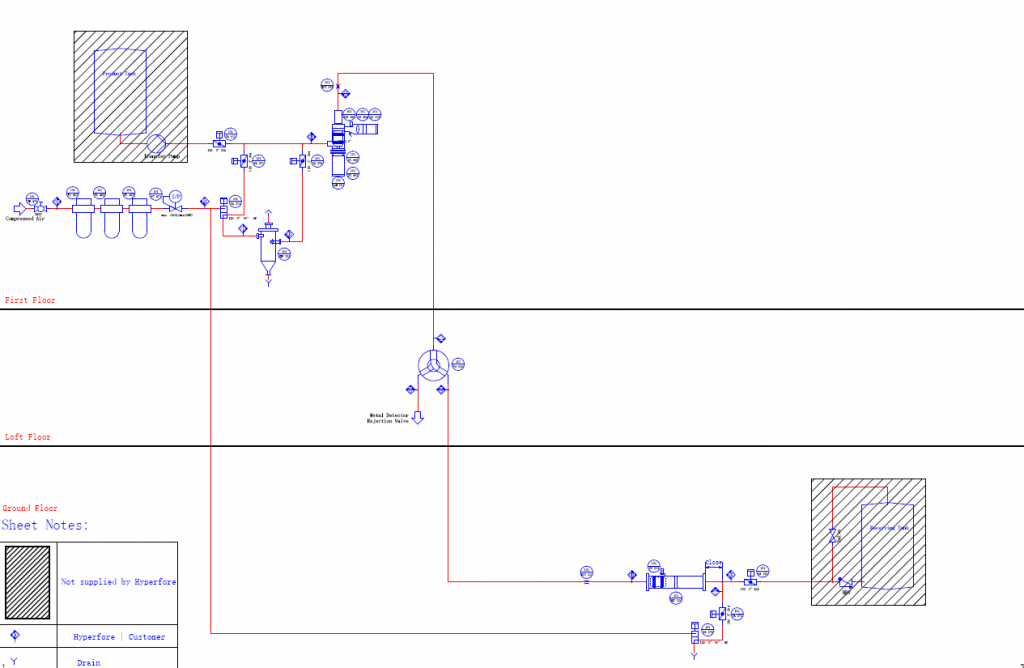

HYPERFOER piggable 3-way diverter valve features a sanitary design, seamlessly integration into pigging and product transfer from single source to multiple destinations and vice versa.

Hygienic Design

The 3-way diverter valve is hygienic without cleaning dead spots, it is compatible with CIP

Efficient and Safe

It is a substitude for manual piggable diverter panel, reducing human laber and errors, improving efficiency

Suitable for Pigging

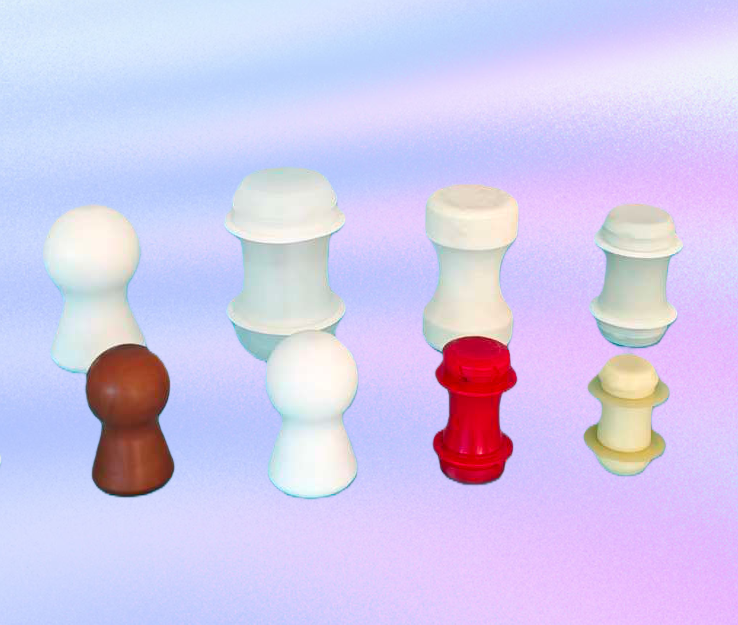

Hyperfore120° 3-way diverter valve is piggable, a pig can pass through the valve smoothly and safely

120° Piggable 3-Way Diverter Valve

Specifically engineered for smooth pigging transitions, this 120° valve prevents the pig from being stuck of jammed with standard 90° Tees.

The 3 ports of the diverter valve are evenly positioned at 120 degree angles. As a result, pigging can start from one starting point to the other two destinations. The product can be transferred smoothly. Its sanitary design makes no cleaning blind spots, both its inner passage and outer shell can be cleaned thoroughly via CIP, it can be seamlessly integrated into pigging manifold solutions.Hyperfore 3-way diverter valve is robust and effective, and maintenance frequency is very low, it is automatic and more efficient than a pigging diverter panel. The 3-way diverter valve is contributed to reduced launching stations, it is suitable for single source to multiple destinations, or multiple source to multiple destinations applications. The piggable valve can be applied across diverse industries, include food, beverage, sauce, syrup, cleaning agent, chemicals, paints, lithium battery slurry.

Typical Applications

Why can this valve replace the manual diverter panels?

Features:

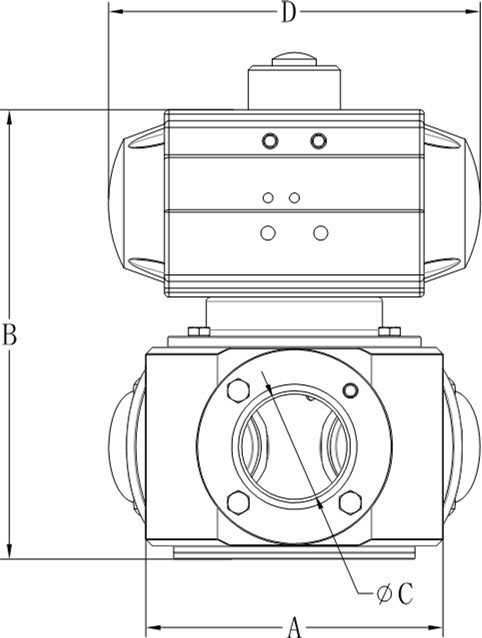

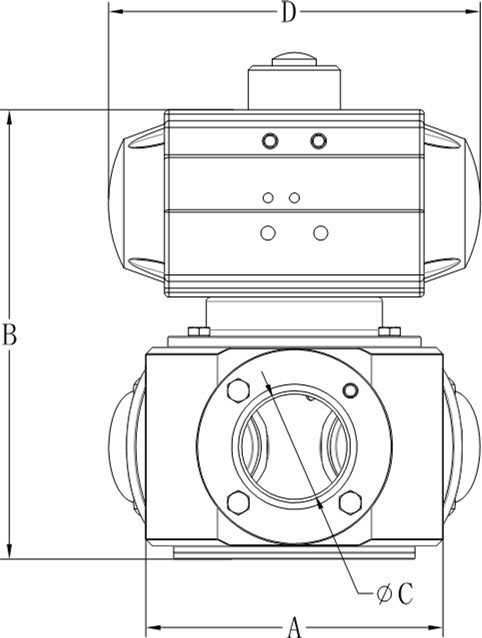

Specifications

| Part No. | Size | C |

|---|---|---|

| VPPTXBAD025A | DN25 | Φ29*1.5 |

| VPPTXBAD032A | DN32 | Φ35*1.5 |

| VPPTXBAD040A | DN40 | Φ41*1.5 |

| VPPTXBAD050A | DN50 | Φ53*2.0 |

| VPPTXBAD065A | DN65 | Φ70*2.0 |

| VPPTXBAD080A | DN80 | Φ85*2.0 |

| VPPTXBAD100A | DN100 | Φ104*2.0 |

| VPPTXBAD125A | DN125 | Φ129*2.0 |

| VPPTXBAD150A | DN150 | Φ154*2.0 |

| Part No. | Size | C |

|---|---|---|

| VPPTXBAT025A | 1″ | Φ25.4*1.5 |

| VPPTXBAT032A | 1.25″ | Φ31.8*1.5 |

| VPPTXBAT038A | 1.5″ | Φ38.1*1.5 |

| VPPTXBAT051A | 2″ | Φ50.8*1.5 |

| VPPTXBAT064A | 2.5″ | Φ63.5*2.0 |

| VPPTXBAT076A | 3″ | Φ76.1*2.0 |

| VPPTXBAT089A | 3.5″ | Φ88.9*2.0 |

| VPPTXBAT102A | 4″ | Φ101.6*2.0 |

| VPPTXBAT127A | 5″ | Φ127*2.0 |

| VPPTXBAT152A | 6″ | Φ152.4*2.0 |

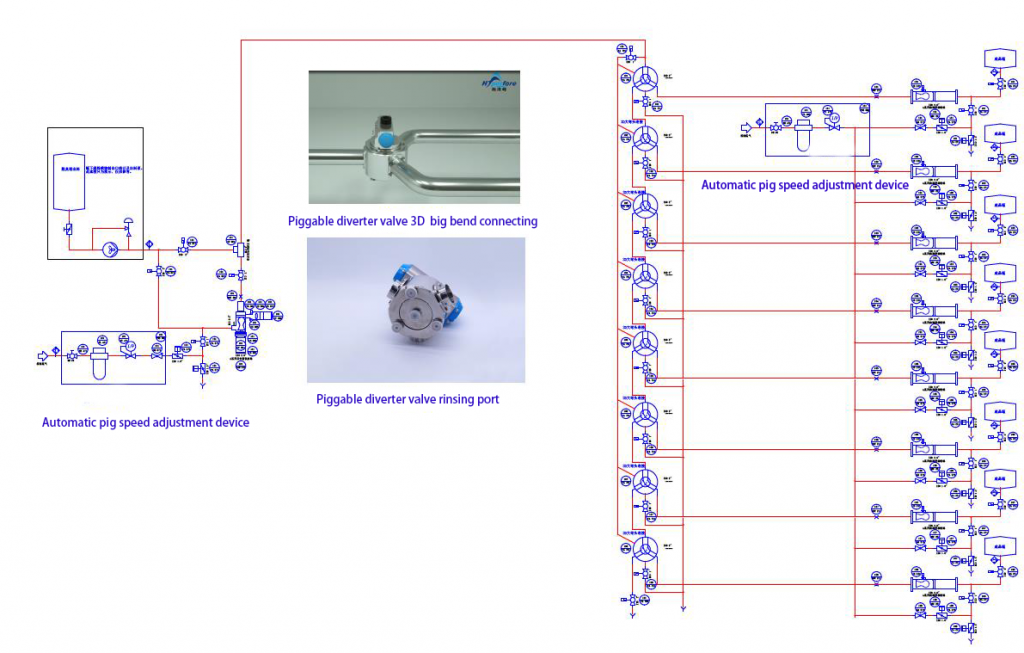

Case Study

This highly efficient recovery process was consistently repeated for all remaining pipelines. As a result, more than 99.5% of the residued toothpaste was saved. Our pigging solution significantly improved yields, reduced waste and enhanced efficiency.

Case Study

Case Studies

The piggable 3-way diverter valve is a key component in our Automatic Pigging Systems.

Frequently Asked Questions

Contact Us

Have questions about piggable valves? Use the form to reach out and we will offer you a custom solution.