Case Study : Sauce Plant Used Pigging System To Reduce Product Waste

Sauce Plant Used Pigging System To Reduce Product Waste

Table of Contents

Case Study- Sauce Plant Used Pigging System To Boost Yielding

Hyperfore supplied sanitary pigging system, and a product recovery solution that substantially boosted the efficiency and profitability of Baili- the China Sauce Company. It finally raised yields, minimized water waste and product waste, and improved environmental sustainability.

Summary

Baili is a renowned food manufacturer in China, specializing in the production of sauces such as salad dressing and tomato sauce. To reduce product waste, Hyperfore supplied and installed one automatic pigging system in their production workshop. The pigging system recovered product in the pipeline connected with a storage tank and transfer them to eight target tanks. In addition, Hyperfore also upgraded Baili’s CIP system from manual to automatic operation. Originally, there was only one hot water tank for the CIP system. After our upgrading, we added one caustic water tank and one disinfection water tank. The purpose is to ensure the safety and efficiency of the CIP system. All the engineering work allowed the entire production line to be cleaned more efficiently, resulting in a reduction in product waste and increased productivity.

About Baili

China Baili Food Co., Ltd. is a modern food enterprise specializing in the production of salads, fermented bran, flavor sauces, seasoning powders, tomato paste and other catering, baking and seasoning products. The headquarters is located in Dongguan City, Guangdong Province.

Project Background

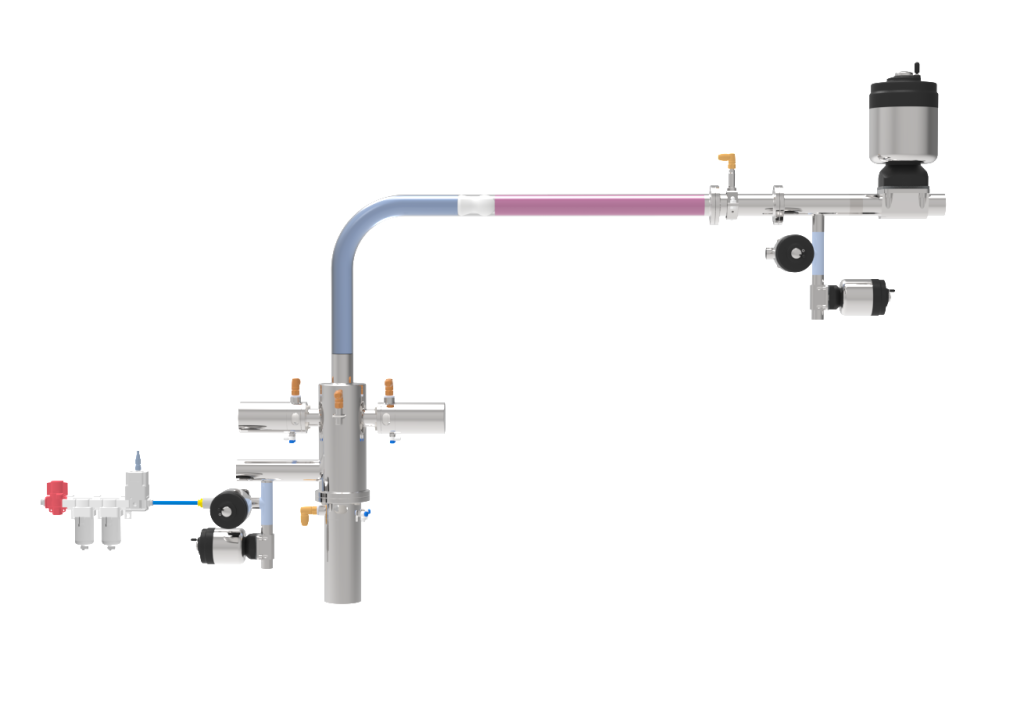

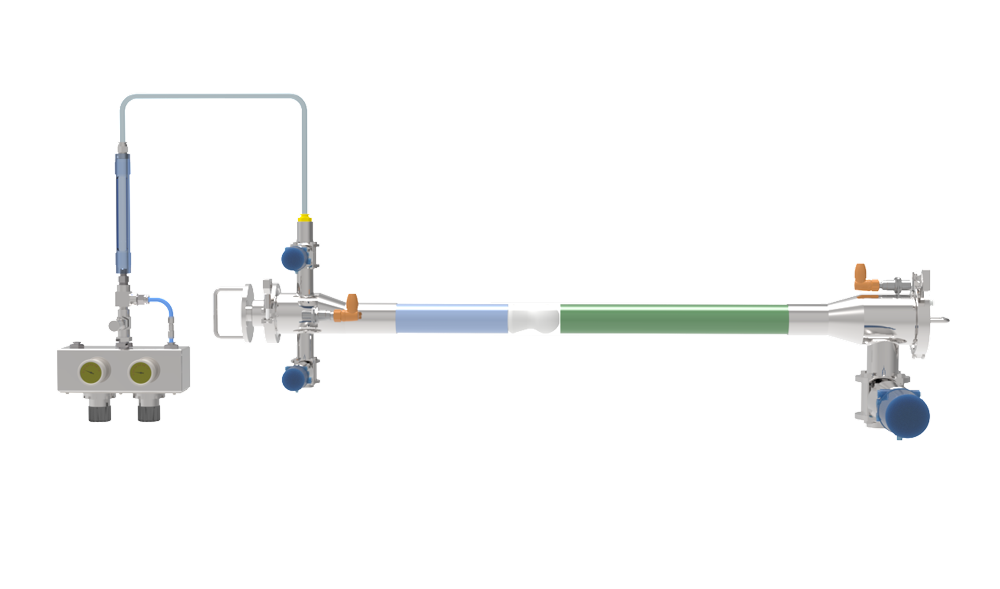

Firstly, there was one pipeline in customer’s workshop that Hyperfore installed pigging system (product recovery system) in. The workshops had a salad sauce production line that is about 50 meters long, with a pipe diameter of 3 inches. The salad sauce was transferred from the storage tank to eight filling machines many times every day. But without any product recovery system in place, a large amount of product was wasted .In addition, the customer also requested an update to their old CIP system in another workshop. The existing manual CIP system was neither efficient enough nor safe enough, so the customer wanted to change it to an automatic system. They chose Hyperfore due to our extensive experience in this field and sought our expertise to provide them with suitable automation solutions.

Hyperfore’s Product Recovery Solutions and Engineering

Pigging System(Product Recovery System)

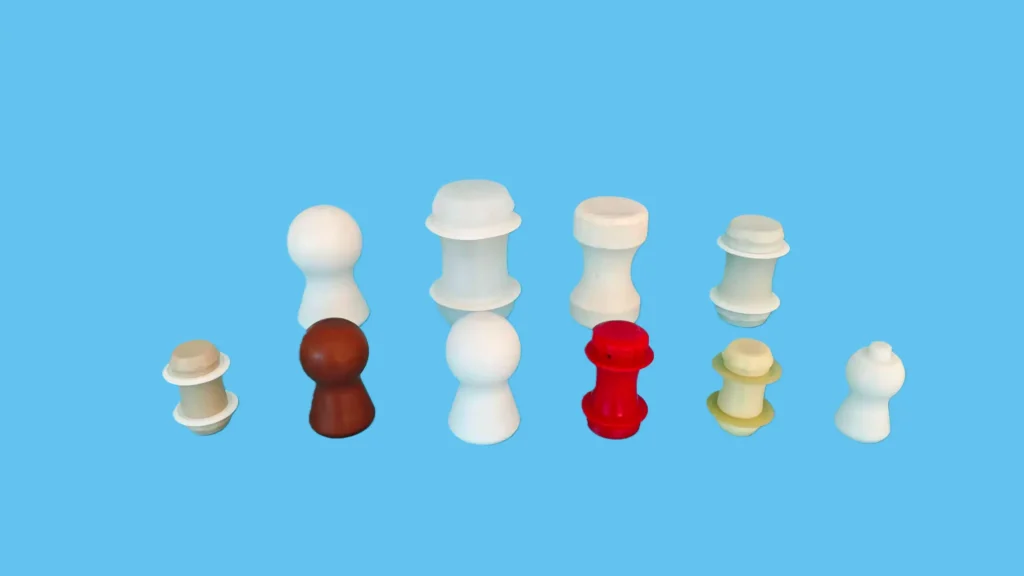

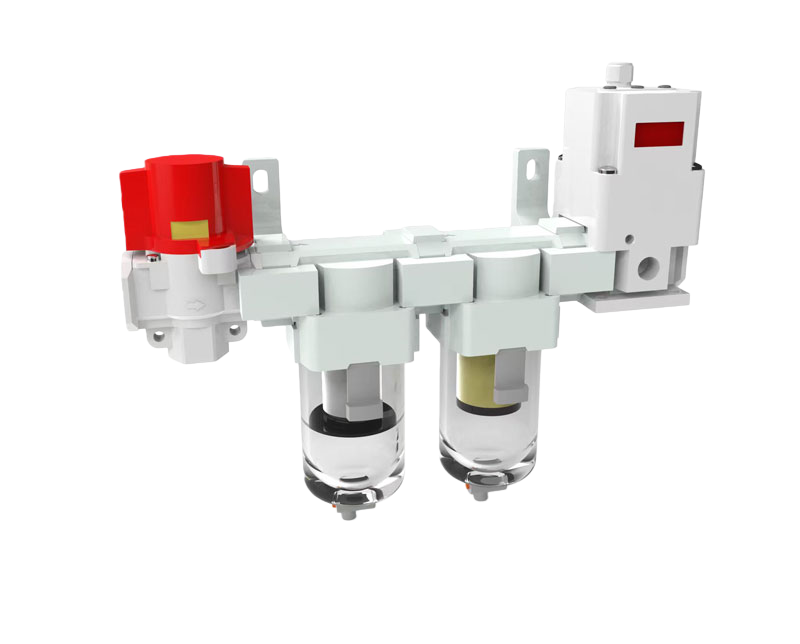

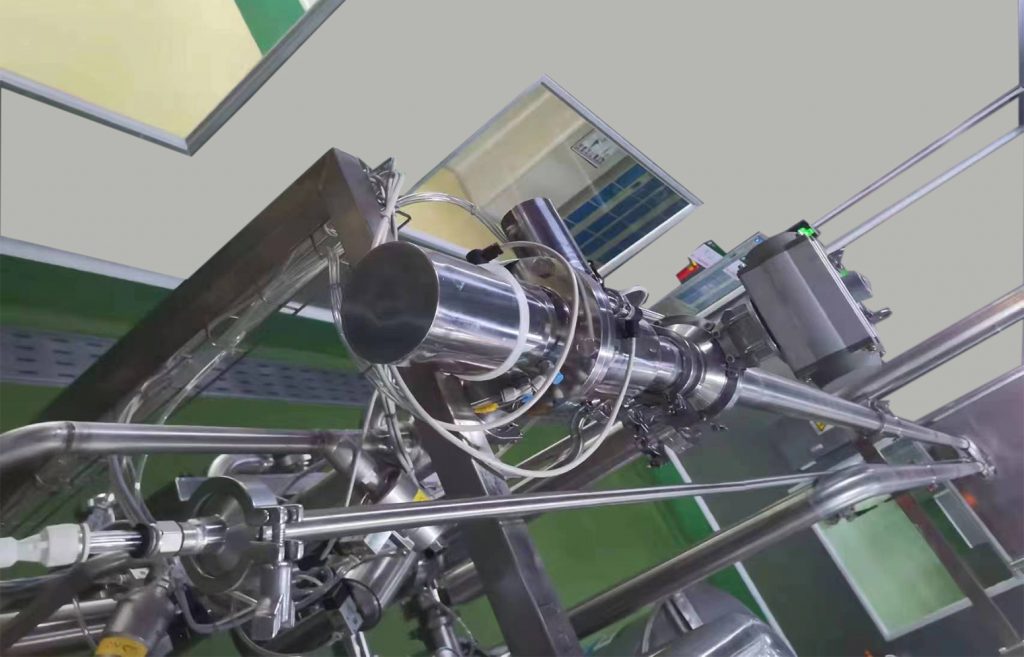

We provided an automatic pigging system for the production line to improve product recovery efficiency and reduce human errors. The system included a launcher and a receiver , a pig, a pig speed controller, cyclone separator, and sterile air filtration to ensure the sanitation safety of pipes and equipment. And these factors would affect salad quality. We also supplied a standalone electrical control panel and an independent PLC system to efficiently control the equipment. Before each separate tank in the branch pipeline, we installed a pig detecting unit, and this will ensure the product will be precisely recovered into target tank.

CIP System

We also updated the old CIP system. The CIP procedure followed the pigging process, that over 99% of the product could be recovered. After pigging, only a thin film of product remained on the inner wall of the pig pipe. The CIP system was designed to remove any remaining product to prevent cross contamination. Another function of CIP system is to sterilize equipment. A tubular heat exchanger was installed to effectively heat the caustic water in the tank, making the CIP system more effective. The pig pipes and devices were thoroughly cleaned during the CIP process. The CIP system upgrading took about two weeks to complete, and the commissioning process took one week, and we made every effort to minimize downtime. Overall, our solution not only improved the efficiency of the production line but also enhanced the quality of the salad products.

Aseptic Air Filtering System

According to customer’s requirement, the propellant media is aseptic air. By filling the compressed air, we can obtain aseptic air. Every 7 to 15 days, the aseptic air filtering system is sterilized by aseptic steam. The system ensured the food safety and hygiene, as a result, it prevented the salad to be contaminated by bacteria.

Customer Feedback

“If we were to rate Hyperfore on a scale of one to five stars, we would give it a rating of 4.5 stars. since we used Hyperfore’s pigging system, we have been able to save 230kg salad sauce every time, and we save approximately 700 dollars every day, which translates to 17.5 thousand dollars per month. The performance of the team was satisfactory. They delivered a high-quality project on time, and the engineers were able to address some emergencies that we faced. We have also made a pact with them to provide timely support whenever we encounter technical problems.” said the Production Manager

“We highly recommend their pigging system for food recovery as it has proven to be very effective in improving the efficiency of our production line.” Hyperfore pigging system can recover over 99% of the product, which can help customer significantly reduce waste and increase productivity. Additionally, our standalone electrical control panel and independent PLC system make customer efficiently control the equipment and minimize downtime. In conclusion, the customer was very satisfied with the results that we has provided them with.

LEARN MORE aBOUT PIGGING SYSTEM PROJECTS

Are you in need of installing hygienic pigging systems to recover sauce, food, drinks, and other liquids? Are you interested in calculating the pigging return on investment (pigging roi)? Do you also hope to update your production process? If so, please do not hesitate to contact us for more information.

Reliable Pigging Products and Quality Pigging Service For Your Project, We Do It All!

RESPONSIBILITY

We oversee the day-to-day activities on site and ensure that project is developed on demand and to a budget.

EXPERT

We coordinate the efforts of various other professionals to ensure we work together to achieve a common goal.

HIGH STANDARD

Our entire team have the same goal of top quality, high standards for health, safety, and good performance.

Related Articles

Hyperfore have many pigging system cases, pigging solutions cases, such as pigging system for mayonnaise recovery, pigging system for lithium battery slurry, pigging system for pharmaceuticals, and so on.

Get In Touch

Have questions about sanitary pigging system or pigging solutions? Hyperfore is proficient in this field. Use the form to reach out and we can tell you more successful pigging system cases.