Essential Auxiliary Pigging Products

We offer a full range of high-quality pigging products

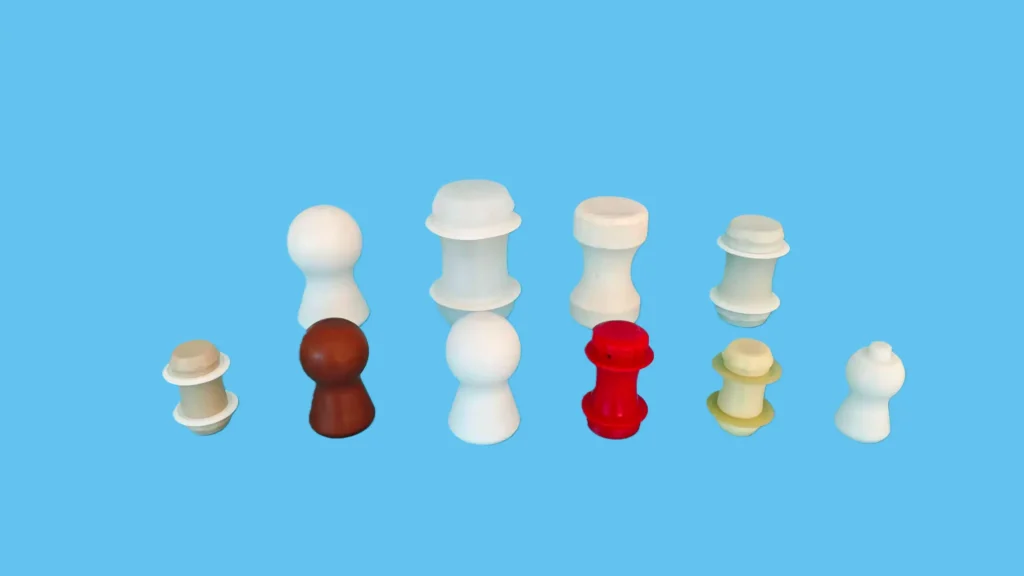

HYPERFORE provides a complete line of auxiliary pigging products for hygienic pigging systems. Our products include: gas-liquid separator, pigging valves, piggable manual swing bend pannel, pipeline pig detector, pig speed controller, back pressure unit, pig stopper, piggable tee, piggable elbows.

These pigging components are suited to dairy, alcohol, beverage, food, pharmaceutical, homecare and household products industries where high level of hygiene are required. Our pigging products are robust, durable and cost-effective.

HYPERFORE pipeline pigging products elevate your pigging system, making it both powerful and perfect. Because they minimize manual intervention, ensuring the pigging operation efficiently and smoothly. By providing customers with a wider array of options to meet the requirements of different processes, these products contribute significantly to reduced product waste, improved production efficiency and enhanced profits.

Precise Control

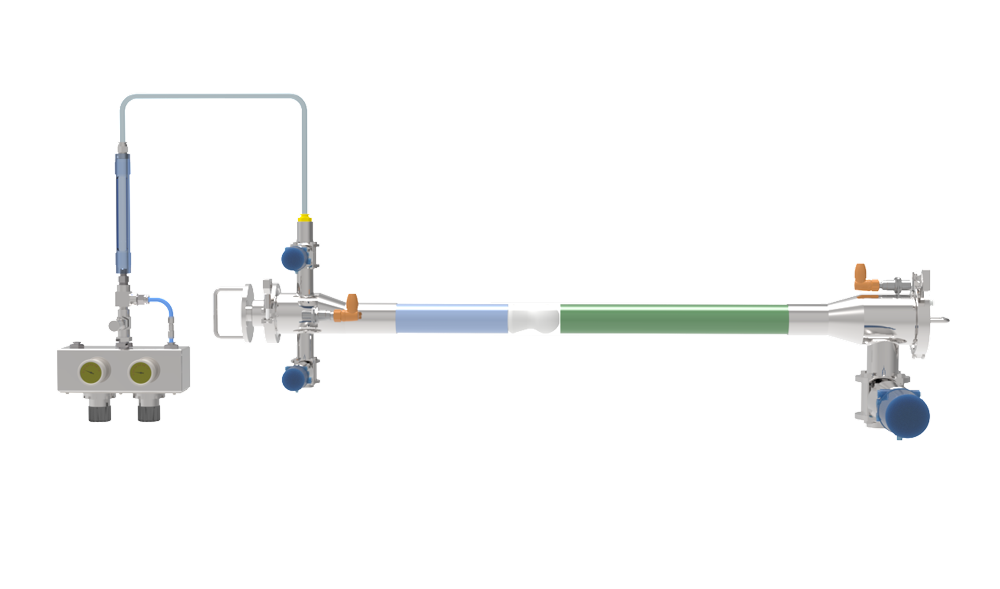

The Hyperfore gas-pressure pig speed controller and mechanical pig speed controller work to maintain constant pig velocity, and ensure steady pipeline pigging process.

Safe Operations

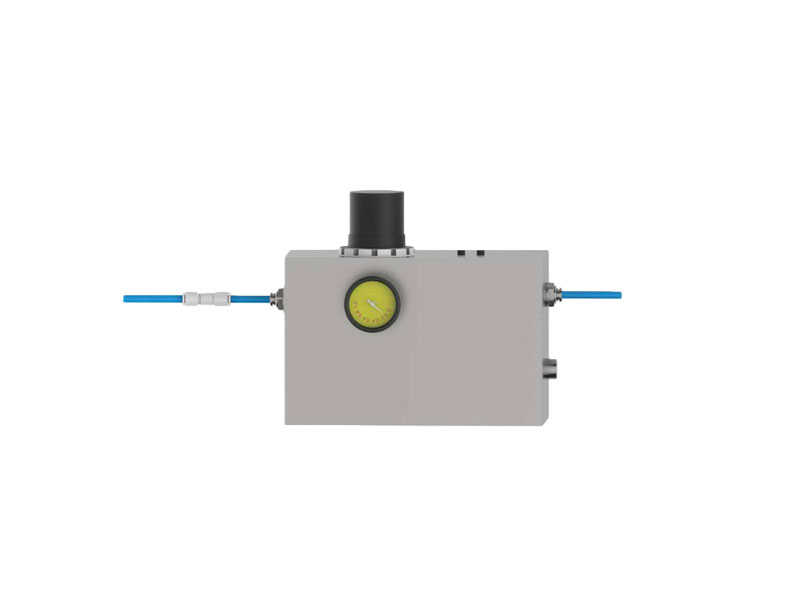

For pressure sensitive pipelines, the Hyperfore back-pressure unit maintains safe pipe pressure level, and the pig detection unit locate the pig position in real-time to prevent pipeline blockage. While our gas-liquid separator ensures safe and hyigienic working environment by preventing dangerous exhaust.

Maximum Recovery

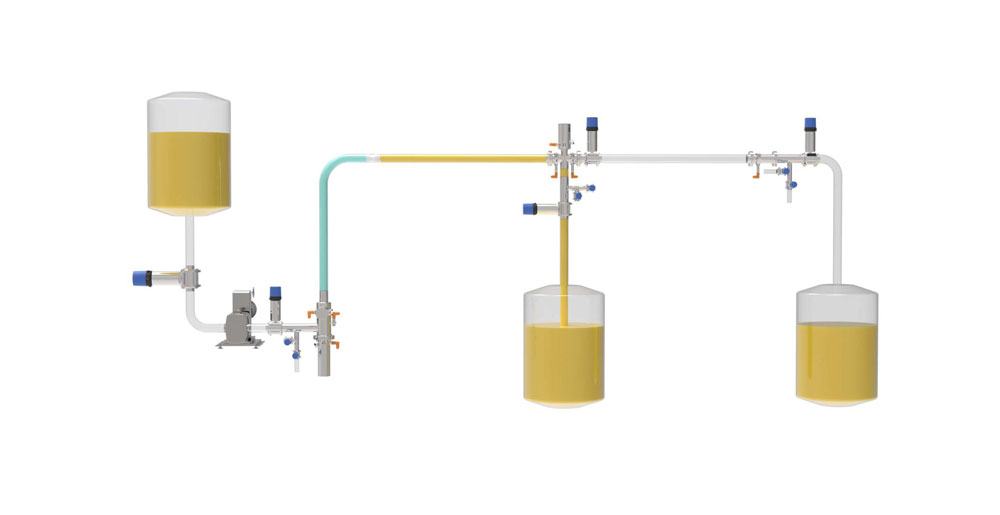

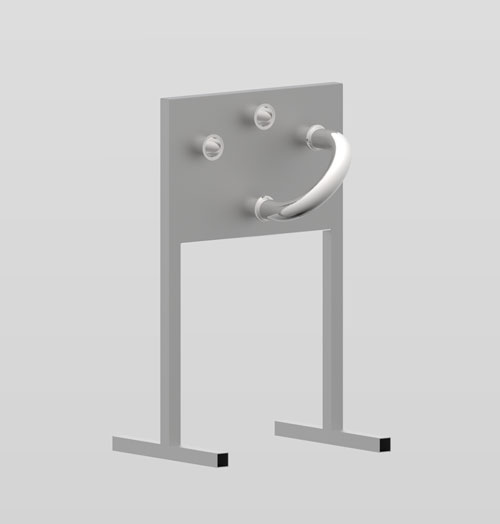

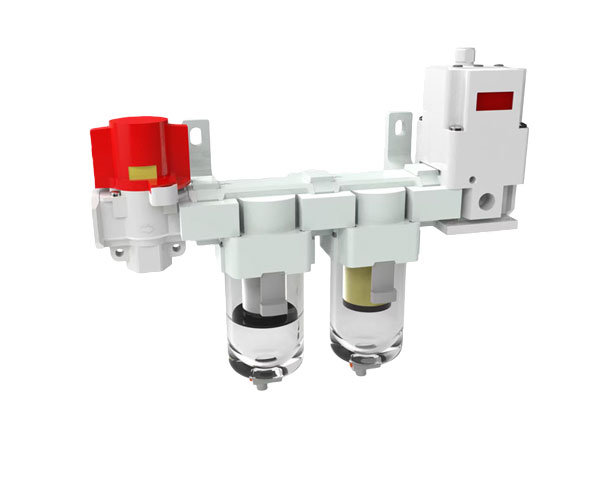

The Hyperfore piggable manual swing bend panel can be seamlessly integrated into the existing pipelines, and allows for multiple source to multiple destination product transfer.

Satisfying Your Specific Pigging Needs

Hyperfore pigging products portfolio for your tailored pigging solution.

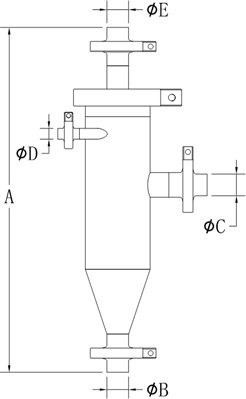

Gas-liquid separator

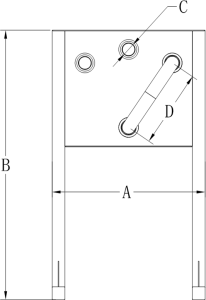

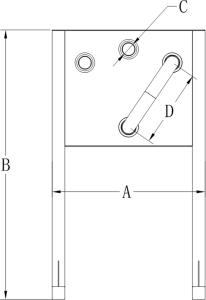

Manual swing bend panel

Mechanical pig speed controller

Pig detection unit

Back pressure unit

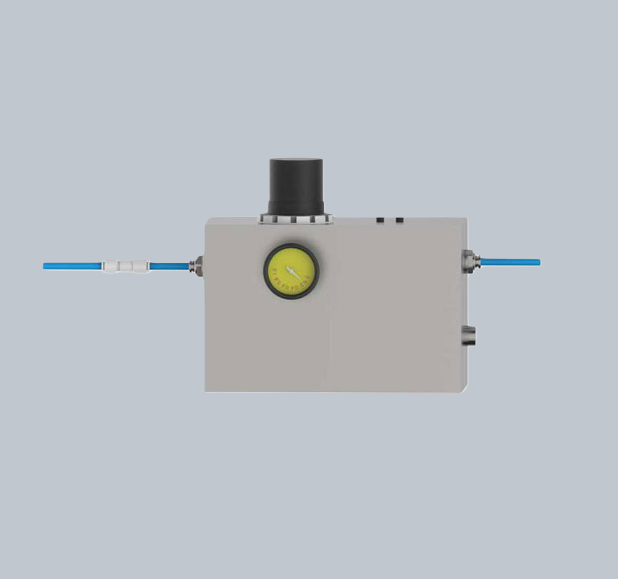

Automatic pig speed controller

Auxiliary Pigging Products Overview

What is the function of a gas liquid separator?

When the pig is returning to the pig launcher from the receiver, a mixture of gas and liquid will be discharged out of the pipeline. This expulsion typically causes splashing, leading to environmental pollution. A gas-liquid separator is utilized to prevent the splashing. With the separator, the gas will be vented from the upper outlet, and the liquid will flow out from the bottom outlet, thereby, eliminating the splashing.

Advantages

Specifications

| Part Nr. | Size | B | C | D | E |

|---|---|---|---|---|---|

| DGLSKAAT013A | 1″-2.5″ | φ25.4*1.5 | φ25.4*1.5 | φ12.7*1.5 | φ25.4*1.5 |

| DGLSKAAT025A | 3″-4″ | φ38.1*1.5 | φ25.4*1.5 | φ25.4*1.5 | φ38.1*1.5 |

| DGLSKAAT050A | 5″-6″ | \ | \ | \ | \ |

| DGLSKAAD015A | DN25-DN65 | φ29*1.5 | φ29*1.5 | φ19*1.5 | φ29*1.5 |

| DGLSKAAD025A | DN80-DN100 | φ41*1.5 | φ29*1.5 | φ29*1.5 | φ41*1.5 |

| DGLSKAAD050A | DN125-DN150 | \ | \ | \ | \ |

Features

Specifications

| Part Nr. | Size | C | D |

|---|---|---|---|

| DMSBKBAD025A | DN25 | Φ29*1.5 | 150 |

| DMSBKBAD040A | DN40 | Φ41*1.5 | 240 |

| DMSBKBAD050A | DN50 | Φ53*1.5 | 300 |

| DMSBKBAD065A | DN65 | Φ70*2.0 | 390 |

| DMSBKBAD080A | DN80 | Φ85*2.0 | 480 |

| DMSBKBAD100A | DN100 | Φ104*2.0 | 600 |

| DMSBKBAD125A | DN25 | Φ129*2.0 | 750 |

| DMSBKBAD150A | DN50 | Φ154*2.0 | 900 |

| Part Nr. | Size | C | D |

|---|---|---|---|

| DMSBKBAT025A | 1″ | Φ25.4*1.5 | 152.4 |

| DMSBKBAT032A | 1.25″ | Φ31.8*1.5 | 190.8 |

| DMSBKBAT038A | 1.5″ | Φ38.1*1.5 | 228.6 |

| DMSBKBAT051A | 2″ | Φ50.8*1.5 | 304.8 |

| DMSBKBAT064A | 2.5″ | Φ63.5*2.0 | 381 |

| DMSBKBAT076A | 3″ | Φ76.1*2.0 | 456.6 |

| DMSBKBAT089A | 3.5″ | Φ88.9*2.0 | 533.4 |

| DMSBKBAT102A | 4″ | Φ101.6*2.0 | 609.6 |

| DMSBKBAT127A | 5″ | Φ127*2.0 | 762 |

| DMSBKBAT152A | 6″ | Φ152.4*2.0 | 914.4 |

Features

Specifications

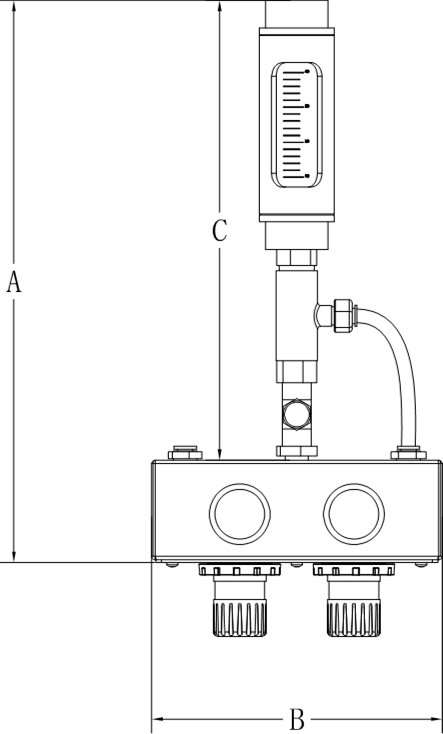

| Part Nr. | Size (L/min) | A | B | C |

|---|---|---|---|---|

| DPSCLAXX100A | 10-100L/min | 430 | 210 | 350 |

| DPSCLAXX200A | 20-200L/min | 430 | 210 | 350 |

| DPSCLAXX400A | 40-400L/min | 430 | 210 | 350 |

| DPSCLAXX01KA | 100-1000L/min | \ | \ | \ |

| DPSCLAXX02KA | 200-2000L/min | \ | \ | \ |

Pig detection unit introduction

The pig is invisible as it travels through the pipeline, so a pig detector is utilized to accurately detect the pig’s position. The stainless steel bolt assembly securely fastens the male and female parts of the clamp around the pipeline.

The magnetic sensor is fixed on the clamp male part and locked by the self-contained nut piece to prevent vibration and detachment.

Pig detection unit – type A specifications

| Part Nr. | Size | Range(mm) |

|---|---|---|

| DPDULOXT025A | 1″ | 60 |

| DPDULOXT032A | 1.25″ | 60 |

| DPDULOXT038A | 1.5″ | 60 |

| DPDULOXT051A | 2″ | 60 |

| DPDULOXT064A | 2.5″ | 60 |

| DPDULOXT076A | 3″ | 60 |

| DPDULOXT089A | 3.5″ | 60 |

| DPDULOXT102A | 4″ | 100 |

| DPDULOXT127A | 5“ | 100 |

| DPDULOXT152A | 6” | 100 |

| Part Nr. | Size | Range(mm) |

|---|---|---|

| DPDULOXD025A | DN25 | 60 |

| DPDULOXD040A | DN40 | 60 |

| DPDULOXD050A | DN50 | 60 |

| DPDULOXD065A | DN65 | 60 |

| DPDULOXD080A | DN80 | 60 |

| DPDULOXD100A | DN100 | 100 |

| DPDULOXD125A | DN125 | 100 |

| DPDULOXD150A | DN150 | 100 |

Pig detection unit – type B specifications

| Part Nr. | Size | Range(mm) |

|---|---|---|

| DPDVLOXT025A | 1″ | 60 |

| DPDVLOXT032A | 1.25″ | 60 |

| DPDVLOXT038A | 1.5″ | 60 |

| DPDVLOXT051A | 2″ | 60 |

| DPDVLOXT064A | 2.5″ | 60 |

| DPDVLOXT076A | 3″ | 60 |

| DPDVLOXT089A | 3.5″ | 60 |

| DPDVLOXT102A | 4″ | 100 |

| DPDVLOXT127A | 5“ | 100 |

| DPDVLOXT152A | 6” | 100 |

| Part Nr. | Size | Range(mm) |

|---|---|---|

| DPDVLOXD025A | DN25 | 60 |

| DPDVLOXD040A | DN40 | 60 |

| DPDVLOXD050A | DN50 | 60 |

| DPDVLOXD065A | DN65 | 60 |

| DPDVLOXD080A | DN80 | 60 |

| DPDVLOXD100A | DN100 | 100 |

| DPDVLOXD125A | DN125 | 100 |

| DPDVLOXD150A | DN150 | 100 |

Features

Specifications

| Part Nr. | Size |

|---|---|

| DPOROOOT025A | 1″ |

| DPOROOOD025A | DN25 |

| DPOROOOT025B | 1″ |

| DPOROOOD025B | DN25 |

Features

Specifications

| Part Nr. | Flow Rate |

|---|---|

| DWFDXOXO450A | 40‐450 L/min |

| DWFDXOXO01KA | 100‐1200 L/min |

Related Articles

FAQ

Contact Us

Have questions regarding pigging products? Use the form to reach out, we will contact you as quickly as possible.