Pigging System in Paint Industry

Paint production and its challenges

Paint is typically made up of several main components: pigments, binders, solvents and additives

Solvents refer to liquids that are used to dissolve or disperse the other components of paint, such as pigments, additives.

Solvents include several types:

Binders used in paint production are generally liquid or in a state that can be made liquid. Binders include the following types:

- Acrylic binders:

- Alkyd binders (oil-based):

- Epoxy and Polyurethane binders:

- Natural binders:

In the paint manufacturing, the solvents play a very important role, they act as the medium to dissolve or disperse pigments, additives, or some binders. The solvents are pumped and sent in pipes to finish the tasks. Once all the components are properly dissolved and dispersed, they are blended with the binders, and the final liquid mixture-paint is pumped and transferred via pipes to the dedicated storage area for quality inspection and filling.

During the paint and solvent transfer process, a significant amount of residue product inevitably remains in the pipes, it is viscous and hard to be cleaned. Moreover, without proper recovery method, the leftover is normally treated as waste, flushed away with a lot of water and cleaning agents. The traditional method of residue product treatment and pipeline cleaning is inefficient, leading to considerable product waste and high water and agents consumption.

What is a pigging system and the benefits of using it?

A pigging system is a set of equipment that can clean the liquid transfer pipeline and at the same time recover the residue product in the pipelines. Essentially, if a liquid can be pumped, it can also be pigged.

Pigging systems emerge as effective tools for addressing the problems of liquid transfer pipeline cleaning and product recovering, including paints and coatings. They not only recover the residue paints in the pipelines, but also thoroughly clean the pipes. The pigging process brings benefits like industrial paint pipeline cleaning, minimal paint waste, enhanced paint yield, lower water consumption, improved operation efficiency, working safety and environmental sustainability.

How to reduce solvent waste in paint manufacturing

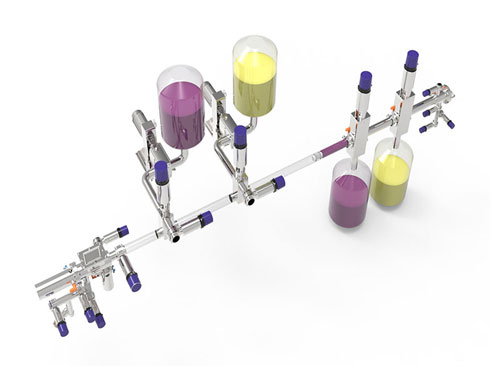

Hyperfore offer customized pigging solutions to address the product waste issues in paint manufacturing. Our pigging solutions include single-pig system, double-pig system, pigging system with piggable diverter valves and piggable manifold, our pigging system in paint industry caters for your unique needs.

In the simplest form, a Hyperfore pigging system is composed of 3 parts: a launcher, a receiver and a pipeline pig. Our pipeline pigs are robust and efficient; the materials have excellent chemical compatibility with the solvents and paints conveyed in the pipelines. The design of our launcher and receiver features low retention, especially suitable for paint application, where preventing cross-contamination between different colors in the same pipeline is very important.

Hyperfore pigging system in paint industy can recover over 99% of the products in the pipes by maximum, minimizing solvent and paint waste, and considerably enhanced yield, The results are manufacturers can largely increase profits, as the financial benefits from recovering valuable paints and solvents are certainly considerable.

Automatic pigging for multi-color paint lines

In paint manufacturing, the task for paint pipeline cleaning could be time consuming and costly.

The downtime caused by waiting for the batch changeovers is very long, paints of multiple colors may share the same pipeline every day, while traditional method for pipe cleaning could prolong the changeover time, largely reduce the production cycles.

This is why pigging system is a game-changer. The implementation of pigging system in paint industry achieves the recovery of over 95% of the residue product in the pipelines, leaving only a little leftover to be cleaned by water and agents. The task of pipeline cleaning is simplified and much more cost is saved. Since less time is consumed for cleaning, overall plant uptime is boosted. The time for cleaning pipes between different paint batches or colors is also dramatically reduced, leading to more production cycles.

Ultimately, by using piggable paint supply system, manufacturers can save human labor and resources like water, powder and cleaning agents, pipeline cleaning becomes easier, and the overall efficiency is boosted.

Improved paint product quality

The paint production pigging helps to achieve thorough cleaning of pipelines. The risk of mixing of different colors or types of paints can be prevented, as a result, the paint manufacturers can get purer products, and each batch of paint produced can meet quality requirements without undesirable residues from the former batches.

Enhanced environmental sustainability

The application of pigging system in paint manufacturing significant decrease water usage for pipeline cleaning, reduce the burden on wastewater treatment. Pigging system also reduces the reliance on harsh chemical usage, creating a green production process.

Improved safety

The implementation of piggable paint supply system also reduces the chances of manual cleaning of the pipelines, and allowing less exposure to chemicals, harmful cleaning agents.

Automatic operation of the piggable paint supply system guarantees the safety and efficiency of the manufacturing process.

Conclusion

Integrating pigging systems into paint manufacturing offers many advantages: reducing solvent waste, reducing paints waste, enhancing paints yield, guarantee product quantity, saving cost and reducing environmental impact.

Ultimately, paint production pigging is a valuable investment for modern paints production plants.

Related Cases

Every month, saving several hundreds of kilograms of product, including sauce, oil, shampoo, chemicals and so on.