HYPERFORE

Pipeline Pigging Process Engineering

HYPERFROE delivers pipeline pigging process engineering not only with regard to pigging system, but the whole production line and the entire production workshop. Depending on our deep understanding of the technological process, we can provide you with professional engineering services.

Experienced

HYPERFORE has accumulated rich experience in industrial and sanitary production process, especially for pipeline pigging process engineering.That is to say, we can implement relevant process engineering design for your product recovery system and other process systems in the plant.

expert

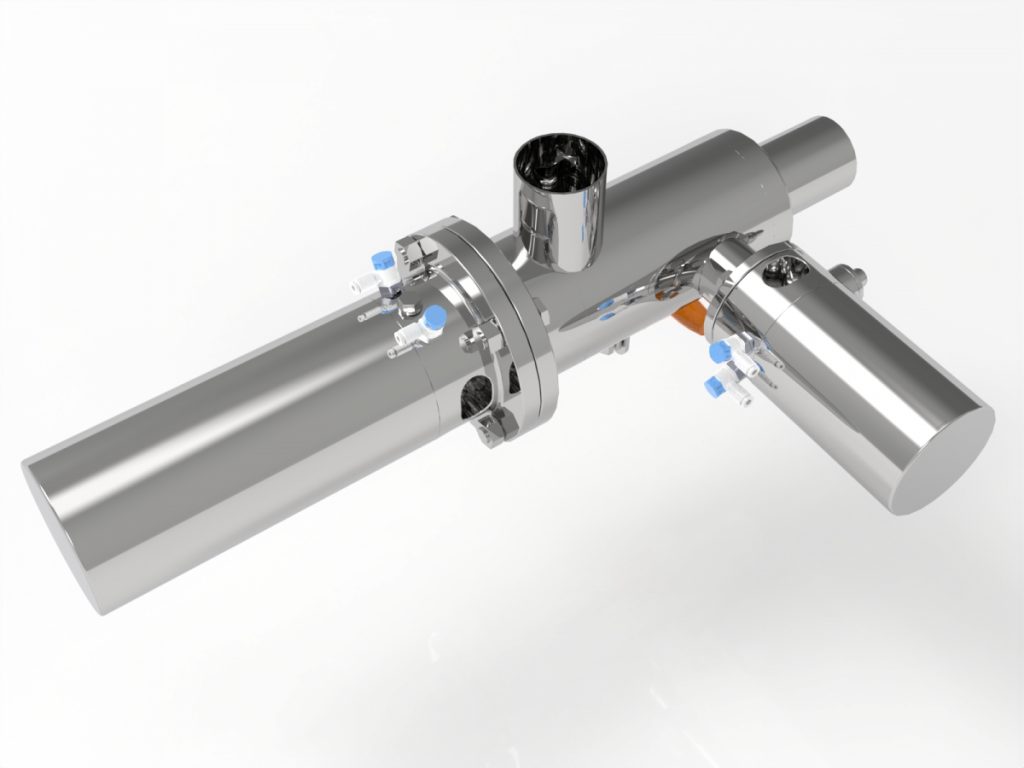

3D pipeline pigging process design service will become very helpful when designing complex valve arrangement or unit system. Before production or installation, 3D pigging system process design can help to visually display the final results, therefore, problems can be found in advance to save implementation costs.

If necessary, HYPERFORE can make 3D drawings for product recovery system and other technological process systems. With 3D drawings it is also easier to integrate our equipment into your pipeline.

HYPERFORE works with the world’s famous process equipment and components suppliers, so that we provide the most suitable equipment and systems. Meanwhile, we can also build new pipelines or upgrade existing systems. Most importantly, we fully understand the customer, and comtribute to the smooth operation and effective production of their factory.

Without doubt, we make safe and efficient solutions at the fastest speed, and deliver turnkey pipeline pigging process engineering to meet your industry application and budget needs.

Widely used

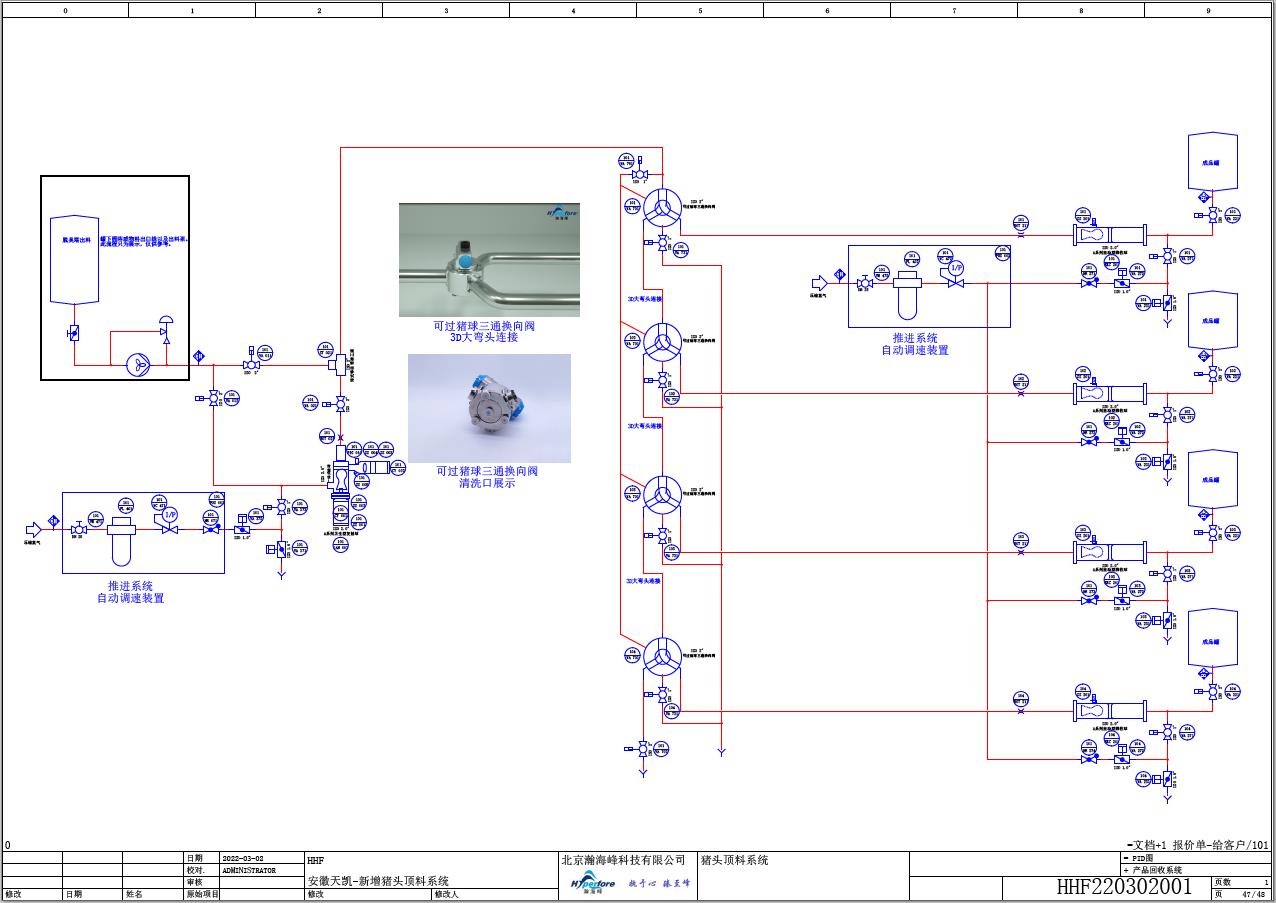

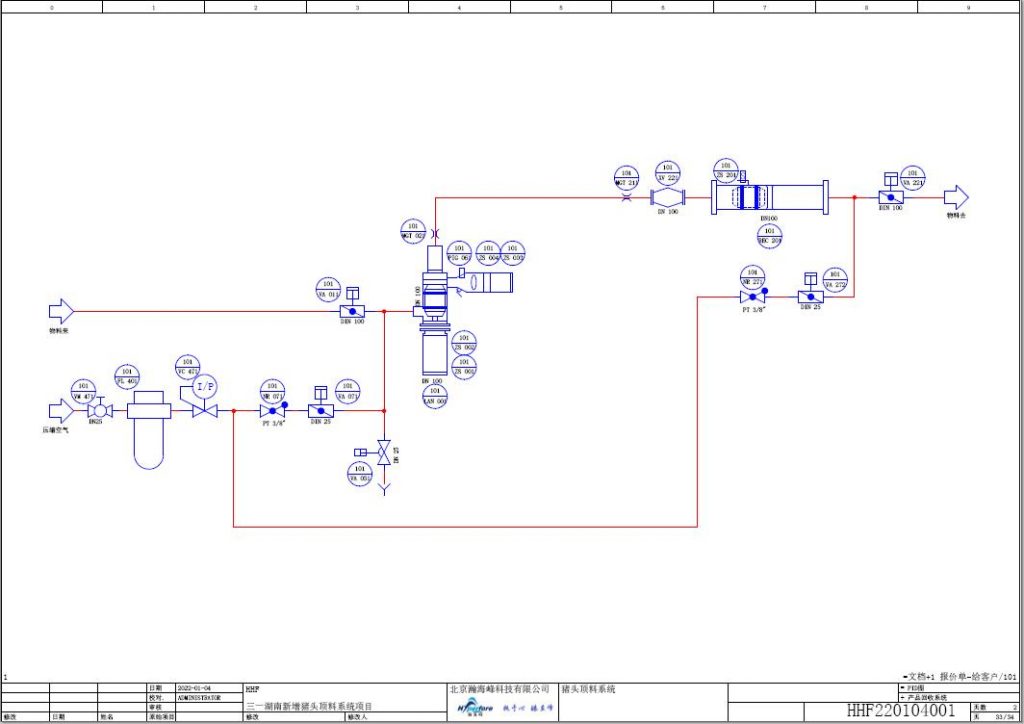

Our pigging system and pipeline pigging process design can serve many industries. For instance, food, dairy, beverage, paint or shampoo, sauce, pet food, lithium battery, and so on. So far, the process systems we designed and delivered include single destination pigging system, multi-destination pigging system, pigging system with valve manifold, etc. Certainly, based on our deep understanding of the process in different industries, and our knowledge and experience, we will design the perfect pigging system for you.

Tell Us Your Special Needs, We Will Provide You With Perfect Pipeline Pigging Process Design

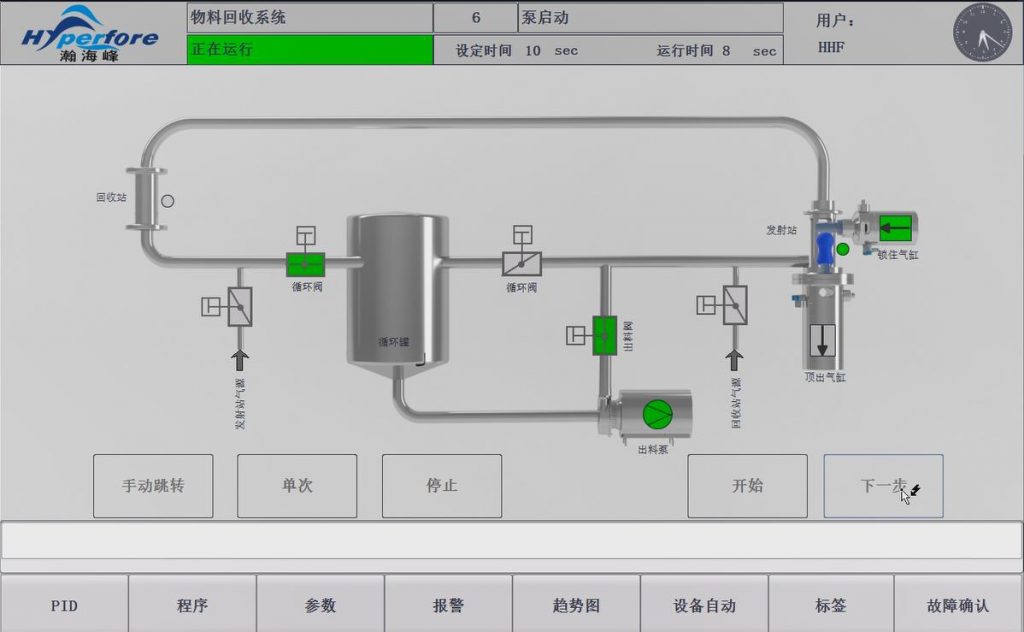

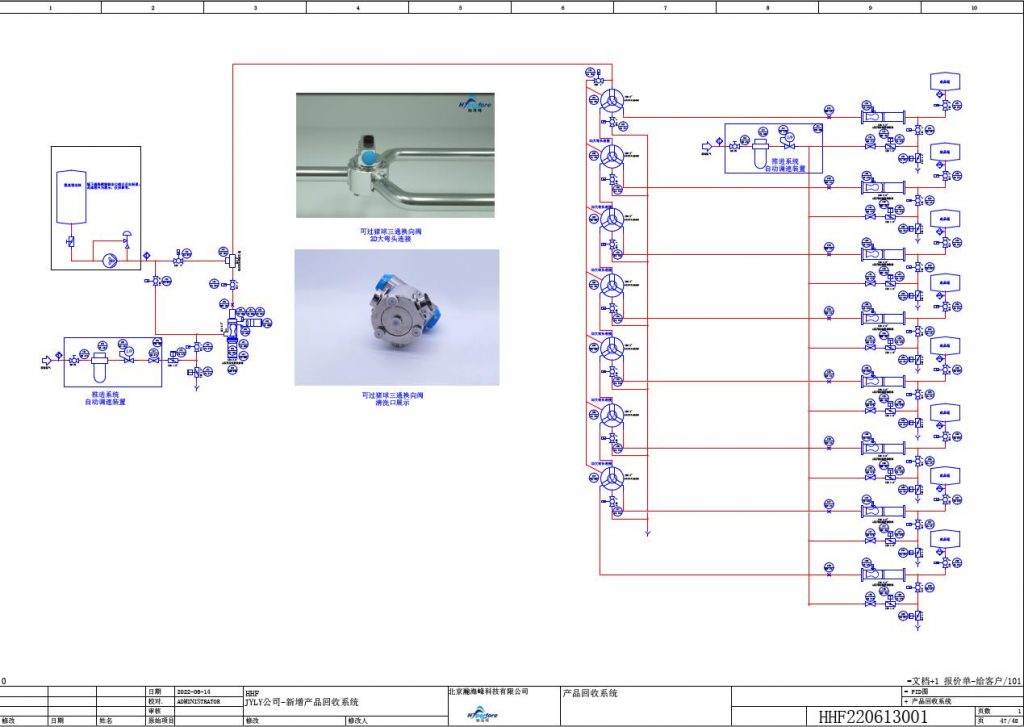

The pigging system from single source to single destination can be applied to almost every industry. Check the design sketch below to understand our basic system configuration. You can customize the system by changing components to meet your specific application needs.

How Does It Work?

After production, there is some residue product in the pipeline. Driven by the sanitary compressed gas, the pig starts from launching station to the receiving station to complete the product recovery process.

After the sanitary pig arrives at the launching station, CIP cleaning starts. It cleans the launching station and pipeline at the same time. Afterwards, the waste water is drained when the process ends.

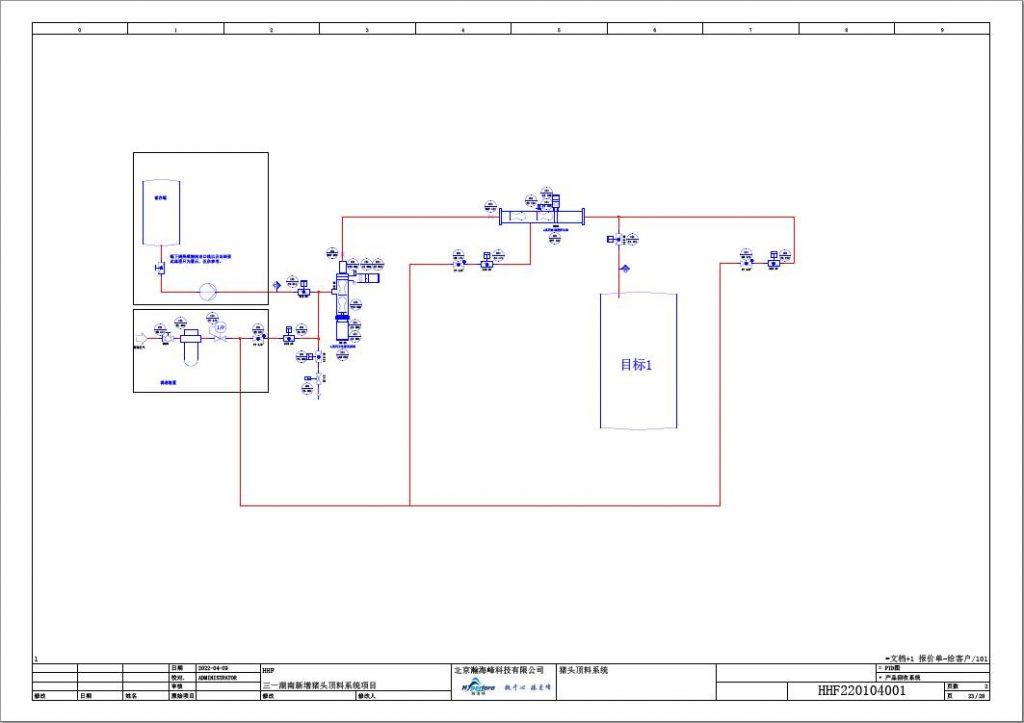

How Does It Work?

At first, the pig starts from the launching station, and arrives at the receiving station with the help of the driving medium.Then, the pig passes multiple targets, and the product can enter any designated target. Because the product line is installed with piggable 3-way diverter valves that the pig can pass smoothly. At last, CIP cleaning starts after the pig goes back to the launching station. Another key point, Hyperfore multi-source to multi-destination pigging system can be talored to requirements.The postion or the quantity of 3-way diverter valves varies according the actual process condition.

How Does a Double Pig Pigging System Work?

Application 1: A double pig pigging system is usually used for recovering products that can’t contact air. At first, one pipeline pig goes towards the receiving station to clear away the air in the pipeline.The driven medium is just the product, when this step ends, the second pig enters the pipeline to recover the product. Finnally, two pigs travels back to the launching station for CIP.

Application 2: between the first pig and the second pig, there can be some cleaning agent, for example, disinfectant or organic solvents, and they can clean the pipeline inner wall.

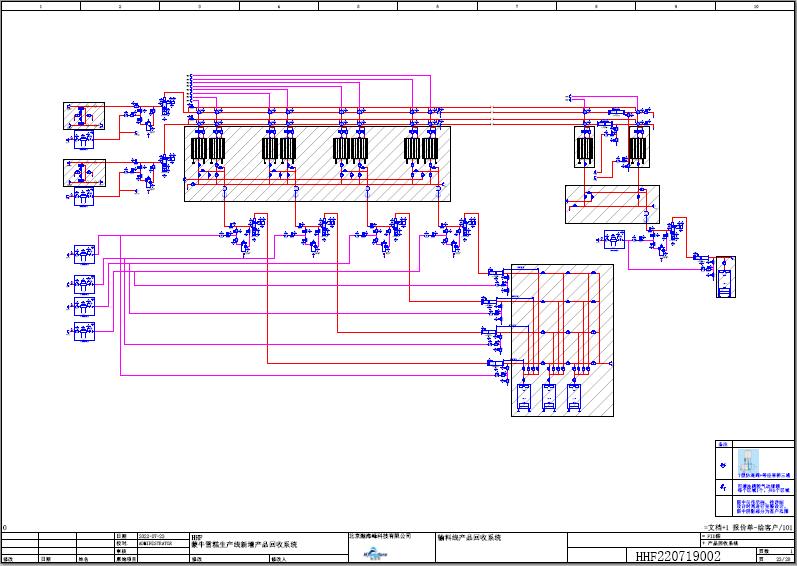

Hyperfore piggable mixproof valve manifolds system is for recovering liquid product transfering from multiple souces to a single target, or from multiple souces to multiple targets. Compared with manual swingbend, the piggable manifold is more efficient and flexible.

Features

Related Articles

Related Products

Download

- pigging system

Contact Us

Have questions about pipeline pigging process or pigging system design? Use the form to reach out and we will be in touch with you as quickly as possible.