A Case Study Of Using Pigging System To Recover Food Oil

A Case Study Of Using Pigging System To Recover Food Oil

Table of Contents

Case Study- China TianKai

How Hyperfore pigging engineering team and our sanitary pigging system and solutions help China DHA oil manufacturer reduce waste, enhance productivity and profits, and maintaining sustainability

Summary

Hyperfore implemented an automation pigging system for Anhui Tiankai Biotechnology Company. And the customer manufactured ingredients oil for DHA production. It is an typical one sauce to multiple targeting tanks project . Our pigging system and solutions allow for the transfer of remaining materials inside the pipes from one production workshop to five outdoor target tanks. The entire project was very cost-effective, and our engineering and pigging service quality were excellent, The customers were very satisfied.

About China Anhui Tiankai

Tiankai Biotech Company was founded in 2007 in Nanjing, China. It is one of the early Chinese enterprises engaged in the production of polyunsaturated fatty acids through biotechnology. Its main products include DHA, ARA, OPO, functional whey protein, probiotics, and allose, among others. These products are widely used in various sectors of the food industry.

Project Background

Our customer was a manufacturer who produced ingredient oil for DHA, which is also a kind of food oil. The production procedure was that the oil came out of the deodorization tower, and then the oil was conveyed through five pipelines to five destination tanks outside the workshop.This was an one by one procedure, not all at the same time. When one tank was filled and this pipeline was closed, then the oil was transferred to anther tank, and so and so until all the five tanks outside the workshop were filled. If the production line was not updated, all the oil in the branch pipeline would have to be wasted. This would be a loss. Meanwhile, the oil remained in the pipeline would deteriorate, also contaminate the all the other product. And this was a risk. In order to avoid ingredient oil waste and product contamination, the customers made up their mind to install a pigging system, after comparing the professionalism and experience of the suppliers, they decided to choose Hyperfore.

Our Solution and Project Implementation

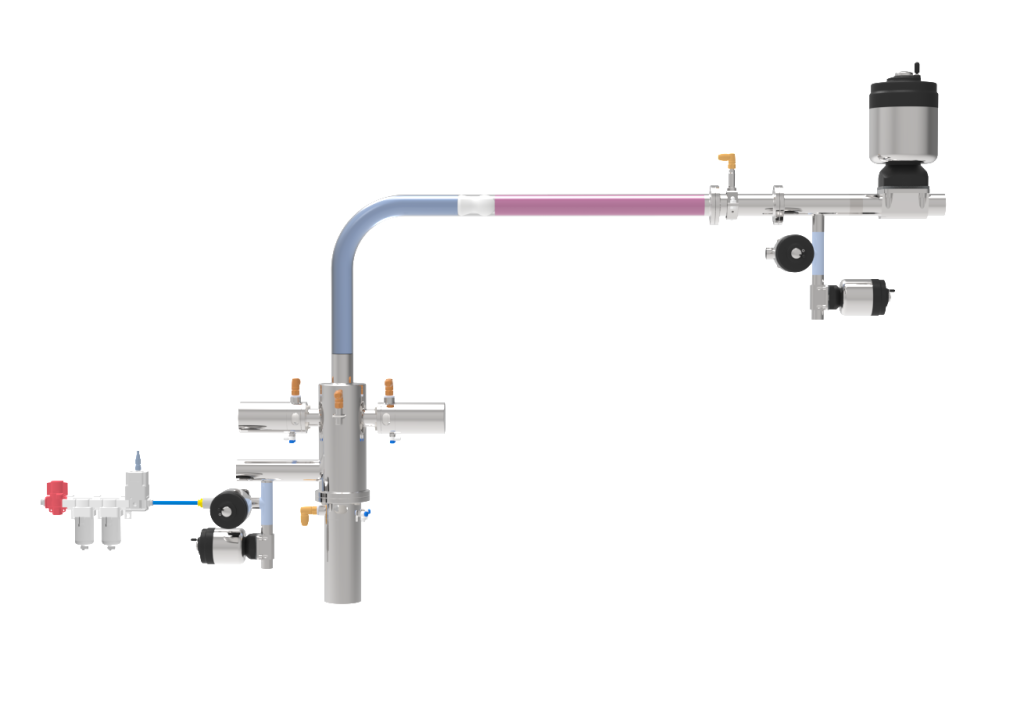

If we used five launching station, the ingredient oil within the pipe which was before the launcher would be wasted. So we chose the 3-way diverter valves to replace the launching stations. This was a pigging project that product was transferred from one source to multiple targeting tanks. In order to save cost for the customers, at the same time, recovering product as much as we could, we recommended the following equipment: one launching station, five receiving stations, four piggable three-way diverter valves, 3D elbows. The distance from the launcher and receivers was about 100meters ,and the pipeline inner diameter was 2 inch, considering the long distance, we recommended two sets of pig speed controllers.

Features Of the Process

During production, the product do not pass the launcher, avoiding the remain of residue oil in the cavity of launcher. This helped to reduce the customers concerns. Because the customer worried that the launcher could not be cleaned thoroughly if there was a lot of oil. The Functions of the 3-way diverter valves: when one pipeline was conveying oil, the others were closed, reducing the possibility of product loss. Secondly, comparing with the hand-operated diverter panel, the piggable diverter valves were more flexible and efficient.They were automated control, do not need human interference, the odds for human error were minimized, too. The valve had a self-cleaning function, do not require disassembly.

Installation Instruction On Site

The customer’s installation team had no experience about pigging system installation. At the beginning, they made some mistakes. The pipes were not welded very well, causing unevenness and misalignment at the interface of the welding. Our engineer guided workers to re-weld the main pipelines, especially those that the pig would pass by. The second thing was that they planned to put the launching station on the second floor of the workshop, the place was not appropriate. After on site investigation, we persuade the customer to change their mind, and install the launcher on the first floor. Because our launcher had to be installed vertically, the pig had to run upwards at the beginning.

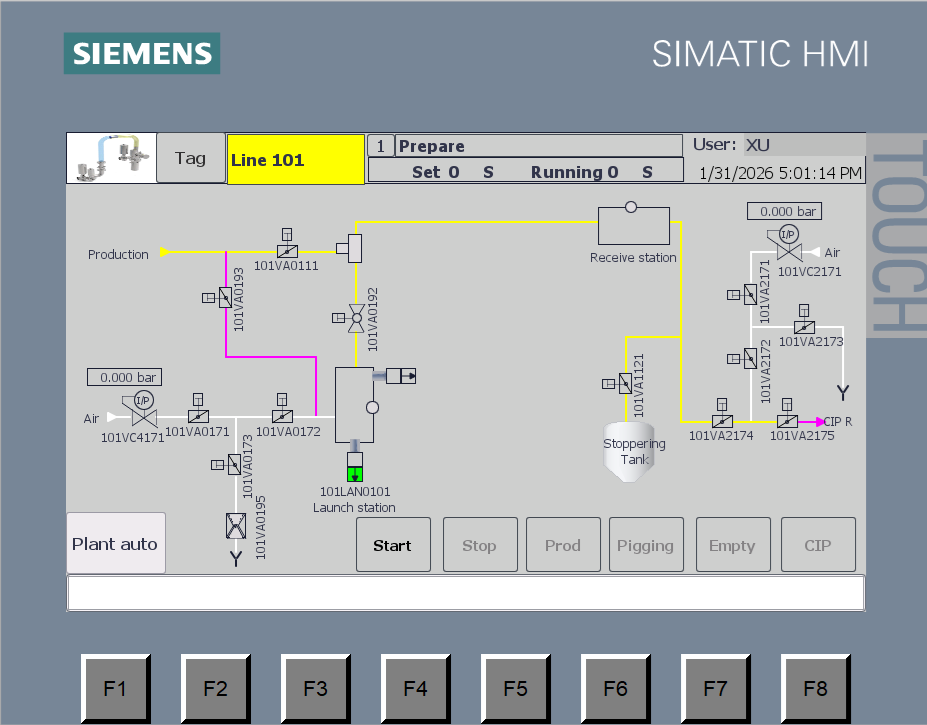

Automation Commissioning and Training

Hyperfore automation engineer came to the site for connection of signal lines with equipment , and signal lines with the electrical cabinet. Afterwards, they conducted the IO test. When IO test was Ok, the production was filled with water for production simulation test. At last, the production test was done. After the commissioning was successfully completed, we trained the customer operators for using the whole pigging system on the HMI. We also handed out an instruction manual with SOP and pigging system process inside for their reference. All the operators were able to use the pigging system in the end.

The Project Result

Throughout the product recovery system project, Hyperfore’s team consistently demonstrated a high level of professionalism and good service attitude. The internal capacity of the one hundred meter pipeline is 0.18 cubic meters, which is approximately 162 kilograms. The pipeline produced two batches each day, which is about 324 kilograms.The is to say, 324 kilograms of ingredient oil was saved after using our sanitary pigging system. Before and after implementing our pigging solution, there are several points to consider for comparison. The production was largely improved, the product waste was reduced, the cleaning of the pipes became easier. And less CIP detergent was used, sewage treatment volume was significantly cut, as a result, the environment was protected. The customer was very satisfied with the project result.

FAQS

Related Articles

Hyperfore introduces relative information about pigging technology from a professional perspective. For instance, we tell the readers about the benefits of hygienic pigging system, the industries that they are applied to, and how they can help manufacturers to gain savings in the shortest possible time.

Related Products

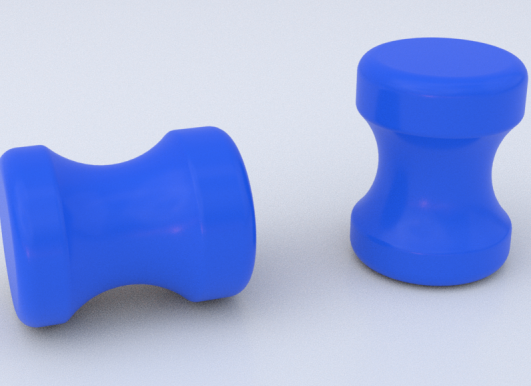

Hyperfore supply automated pigging system, manual pigging system, launching station, receiving station, bi-directional pipeline pigs, pigging products, pigging system process design, pigging system automation control, pigging system services, etc..

Related Cases

Hyperfore has supplied pigging solutions and implemented many pigging systems for a diverse industries of customers, such as pigging system case for food, pigging system case for lithium battery slurry, pigging system case for Chinese medicine (pharmaceuticals),and so on.