Case Of Using Pigging System To Recover Hotpot Sauce

Case Of Using Pigging System To Recover Hotpot Sauce

Table of Contents

Case Study- Teway Food

The Hyperfore Hygienic Pigging System, also known as a product recovery system, has proven to be a game-changer for our Chinese customers-Teway Food, in the hot pot sauce production industry. By optimizing the transfer of sauces and ingredients, it streamlines the production process, significantly increasing productivity.The enhanced efficiency and reduced resource usage enhance the overall competitiveness of our customers in the hot pot sauce market.

Summary

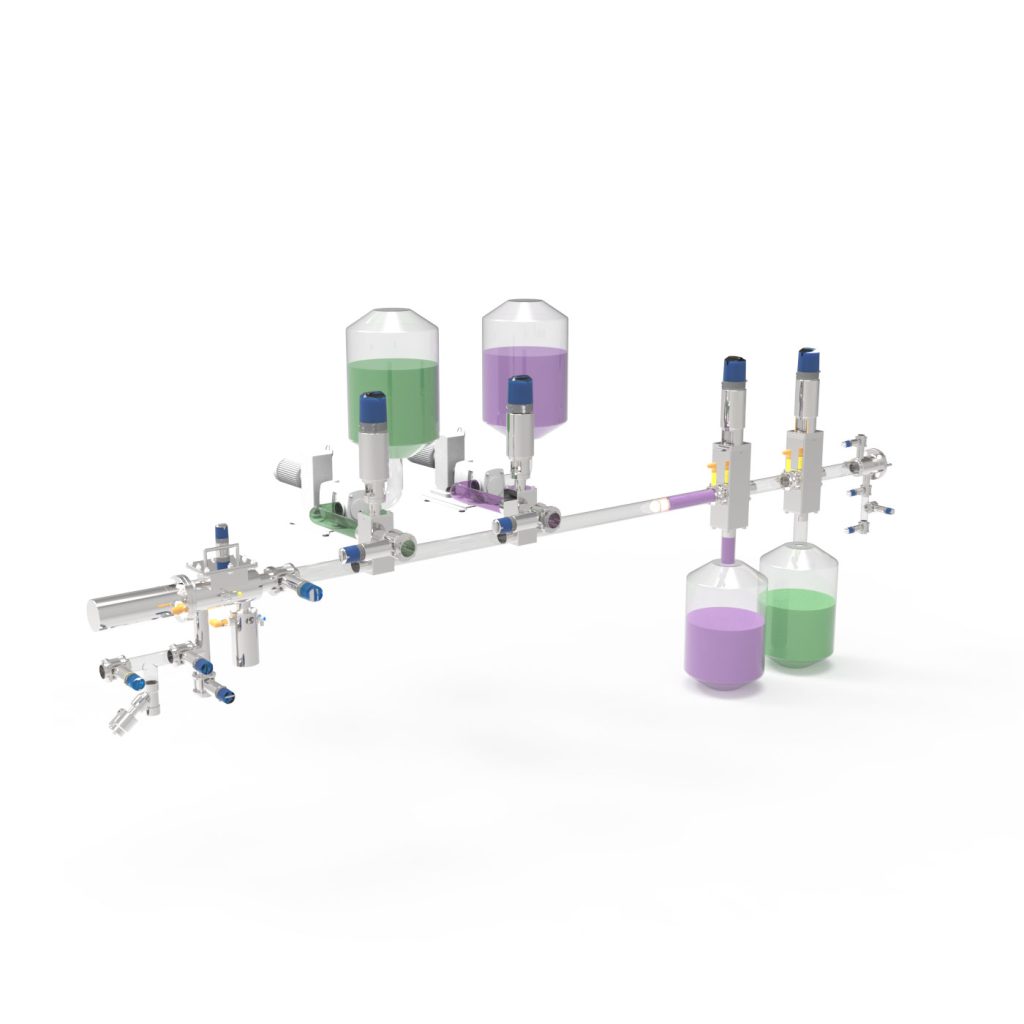

Hyperfore has designed and provided a fully automated 2.0-inch hygienic pigging system for our client, overseeing the installation, commissioning, and offering comprehensive technical support. This innovative pigging solution, known for its high and fast return on investment, effectively reduces sauce wastage, leading to increased production. Moreover, it expedites the transition process on the client’s production line, enhancing operational efficiency. By conserving energy and resources, Hyperfore’s pigging solution actively contributes to the company’s competitiveness and its commitment to environmental sustainability. This technology not only cuts costs but also aligns with our client’s green initiatives, promoting a more sustainable approach to hot pot sauce production.

About Teway Food

Sichuan Tianwei Food Group Co., Ltd. was established in 2007 and is a primarily food manufacturing company. With a mission to “create a better life with deliciousness,” since its inception, the company has been dedicated to the research, production, and sale of compound seasonings. It has now evolved into a major producer of compound seasonings, focusing on hotpot seasonings and Chinese cuisine condiments. Its products are exported to various international markets, including Europe and the Americas.

Customer’s Requirements

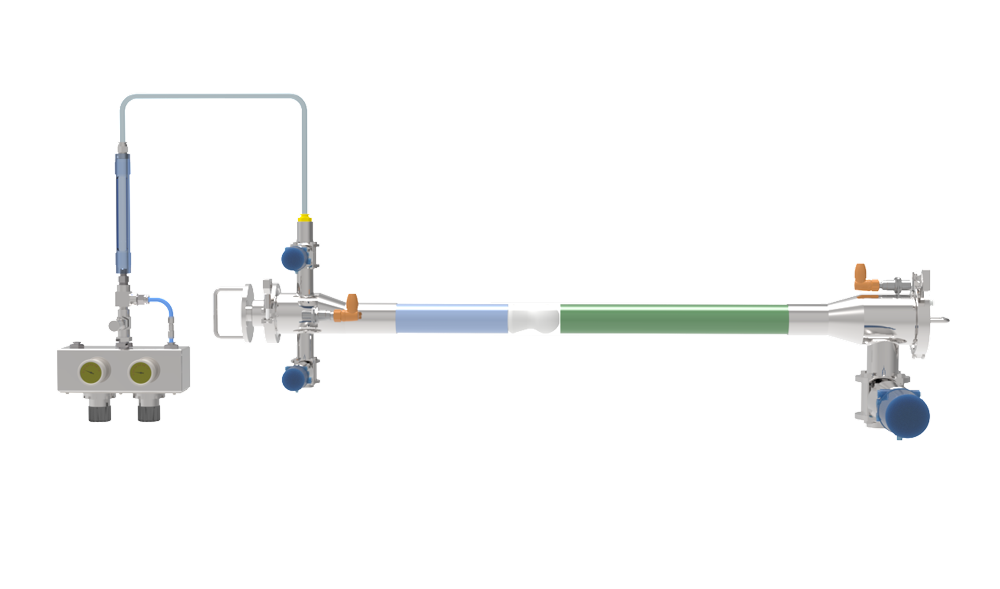

Tianwei Food, proactive in their pursuit of solutions, approached Hyperfore to inquire whether our pigging system could address their current challenges. Following discussions, Hyperfore decided to send engineers to conduct an assessment in Tianwei Food’s production facility. The piping system in their workshop has a 2.0-inch diameter, is intricately routed, and spans over 200 meters.

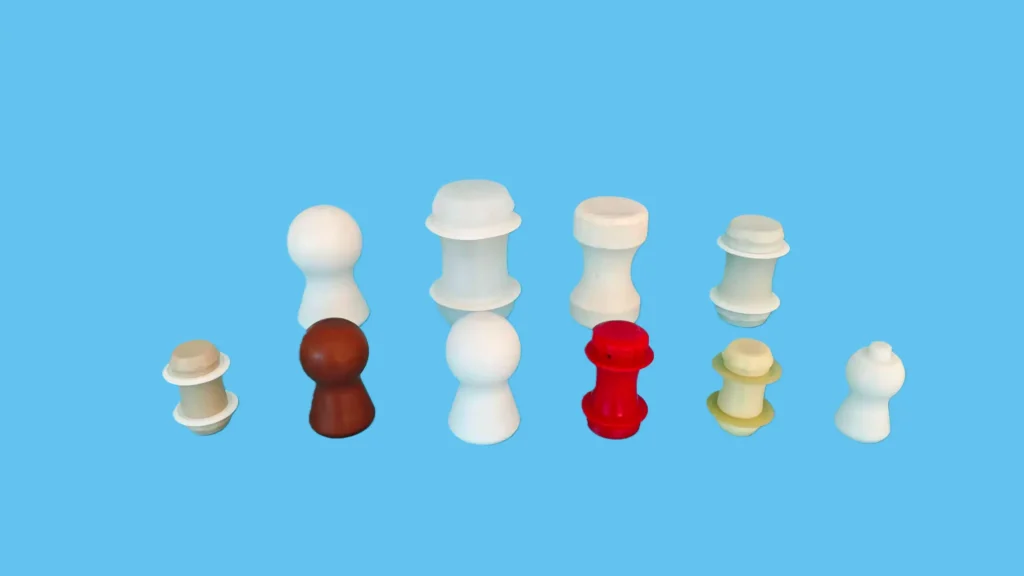

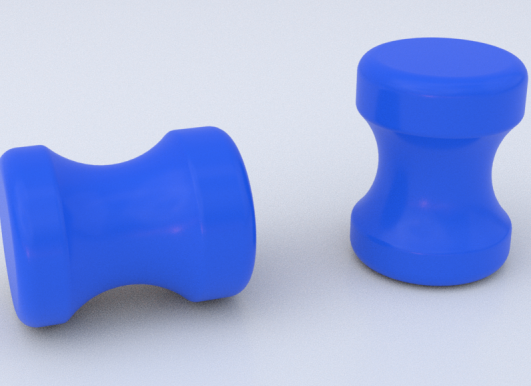

Pigging is a process used to recover residual products from pipelines, increasing efficiency and reducing waste. The bi-directional pipeline pig, a specialized device, moves through the pipelines, pushing out remaining product. This process is particularly valuable in industries like food production, where product loss and contamination are concerns.

Within the Tianwei Food production facility, the distribution of pipelines is complex, with a considerable distance between the production area and the canning area. Due to the high fat content in their products, extensive process and hot water washing is required for pig pipe cleaning. The wastewater generated from these cleaning processes necessitates multiple treatments to meet local government standards for wastewater discharge. This adds a significant cost burden. Therefore, the leadership at Tianwei Food hoped that our pigging system would alleviate the pressure they face in wastewater treatment.

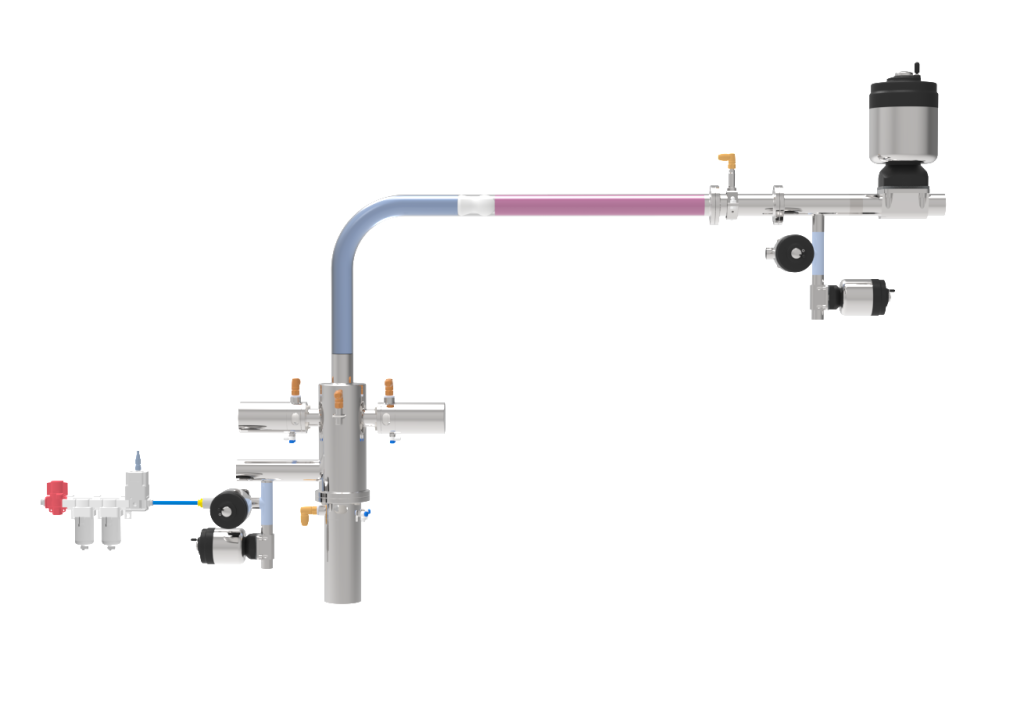

To address these challenges, Hyperfore will need to design a tailored solution that considers the complex pipeline network and the specific requirements of Tianwei Food’s production process. This customized approach aims to not only reduce waste and improve productivity but also minimize the environmental impact by conserving water resources and lowering wastewater treatment costs. The integration of the pigging system with the packaging machinery will be crucial to ensure a seamless and efficient production process.

Choosing the right pigging system involves considering factors such as pig pipe size, product characteristics, and process requirements. Hyperfore is committed to providing Tianwei Food with an innovative solution that aligns with their mission to create a better life with deliciousness while promoting sustainability and cost-efficiency in their operations.

Hyperfore’s Hygienic Automated Pigging System Solutions

Hyperfore has designed and provided a fully automated 2.0-inch hygienic pigging system for our client, as seen in the case of a pigging system for food recovery. According to the design, we have installed a speed controller within the pigging system to precisely regulate the pig‘s velocity within the pipelines. This control ensures that the product discharge rate aligns seamlessly with the packaging machine’s packaging speed.

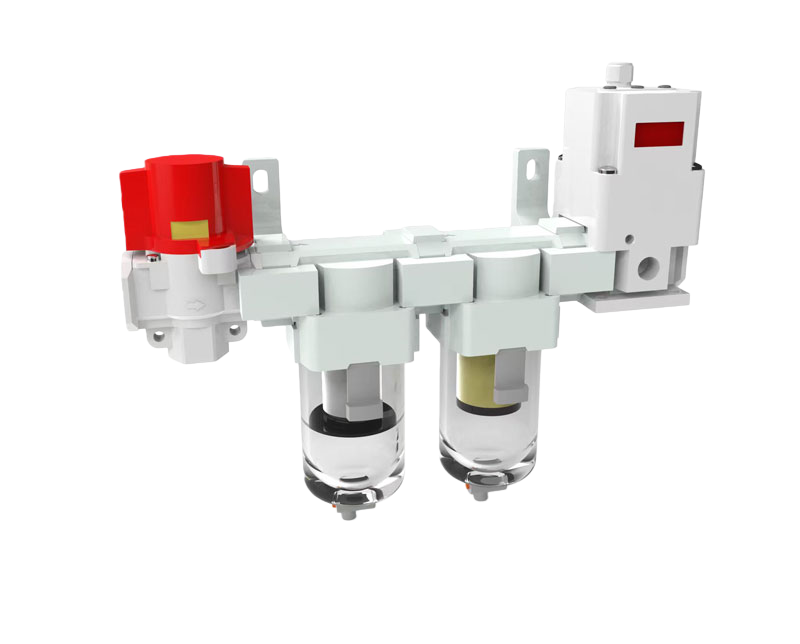

Furthermore, at the sanitary pigging system’s discharge end, we have incorporated a Cleaning-in-Place (CIP) cleaning medium input port. This feature facilitates the cleansing of residual fats adhering to the inner walls of the pipelines using process water and high-temperature steam. Taking into consideration the need for periodic cleaning of the launch device and the pig, the pigging system employs food-grade materials and can withstand temperatures as high as 120°C.

This comprehensive approach not only streamlines the production process but also enhances the hygiene and efficiency of the system, as demonstrated in the case of a pigging system for food recovery. The incorporation of a bi-directional pig speed controller ensures precise control over product discharge, preventing any bottlenecks in the production line. The CIP cleaning feature aids in maintaining optimal cleanliness within the pipelines and tanks, further promoting food safety and product quality. The use of high-quality materials and the ability to withstand high temperatures showcase our commitment to ensuring a robust and dependable solution for our client.

With the implementation of this hygienic system, our client can effectively manage their production processes, reduce waste, and improve overall productivity, aligning with their mission to create a better life through deliciousness. Hyperfore is dedicated to delivering tailored solutions that contribute to our client’s success and their commitment to producing high-quality food products.

The Project Result and Customer’s Feedback

After more than half a month of diligent work, the installation team has successfully completed the installation and commissioning of the pigging system. The pigging system is now fully operational and running smoothly. Typically, the factory operates the pigging system once a day, which means the frequency of sauce recovery is about 20 times per month.

This pigging system has proven to be a game-changer in terms of how pigging system helps savings. Thanks to our innovative solution, the factory saves approximately 0.5 ton of product every week, resulting in a daily cost savings of around 30,000 yuan and a monthly savings of 120,000 yuan. Additionally, the recovered pipelines significantly reduce the expenses and pressures associated with pipeline cleaning and wastewater treatment. The installation costs for the pigging system can be recouped within just three to six months.

Upon project completion, Manager Lv, the client, expressed, “Overall, this project has been highly successful! Hyperfore’s designed pigging system not only recovers sauce from the pipelines but also greatly reduces pipeline cleaning time. This has enabled us to have delivery times roughly half that of our competitors, meeting our business needs effectively. Moreover, Hyperfore offers remote technical support for the system, ensuring that any potential issues are swiftly addressed and allowing us to adapt flexibly to future changes.”

In essence, this project showcases how the pigging system has not only enhanced efficiency and cost savings but has also improved the competitive edge of the client. Hyperfore’s dedication to providing innovative solutions and responsive technical support has led to a successful partnership and an optimally functioning production process. The pigging system stands as a testament to how cutting-edge technology can bring about substantial financial benefits while reducing environmental impact, aligning with sustainable business practices.

Hello,

I’m Richard Gan, General Manager at Beijing Hyperfore Technology Company Ltd.

Since our founding in 2005, we have accumulated almost 10 years of focused experience in the Chinese market, specializing in the design and delivery of advanced sanitary pigging systems and integrated solutions.

If you have any questions, please feel free to contact us. We are pleased to provide you best products and services.

Email: wenbo.gan@hyperfore.cn WeChat: hyperfore2005

WhatsApp: +86 18910216756

Related Products

Hyperfore supply sanitary pigging system, manual pigging system, launching station, receiving station, pipeline pigs, pigging products, pigging system automation, pigging system installation, pigging system services, etc..

Related Articles

Hyperfore supply sanitary pigging system, manual pigging system, launching station, receiving station, bi-directional pipeline pigs, pigging products, pigging system automation, pigging system installation, pigging system services, etc..

Related Cases

Hyperfore have many pigging system cases, pigging solutions case, such as pigging system case for food, pigging system case for lithium battery slurry, pigging system case for Chinese medicine (pharmaceuticals), and so on.