Keep Your Plant Competitive

Do you want a clean, orderly and effective plant? Are you looking for a professsional pigging system installation and commissioning team? Just contact HYPERFORE!

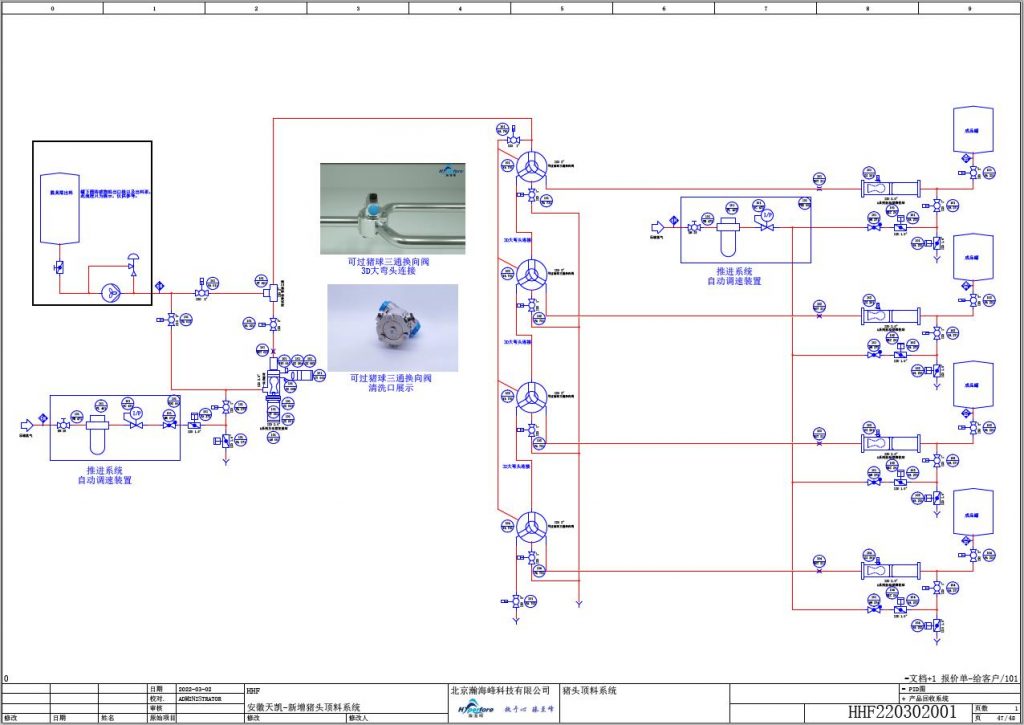

For more than ten years, HYPERFORE has accumulated valuable experience in the field of installation and commissioning, especially for pigging installation. As can be seen, our team has provided high-quality pigging system installation and commissioning services to leading brands manufacturers both home and abroad in many industries.

It is important to realize, professional engineering technique is very important, especially for the pigging system turnkey projects. But HYPERFORE has a good command of the know-how for project implementation, and can avoid common problems from the very beginning. And we offer professional on-site supervision and management.

Pigging Installation Working Process

Our Honor

Experienced and Effecient Pigging Installation Team

In general, our installation work is to seamlessly integrate various unit systems and equipments into customers’ production process. We have delivered many high-quality and cost-effective installation projects, such as pigging installation, and installation for mixing system, filtration system, CIP system, fruit adding system, entire production line and entire production workshop. and partners speak highly of our engineering work.

To upgrade the production line, or do pigging installion work in your new plant?

On-site Commissioning

Certainly, pigging system on-site commissioning needs good organization and management. HYPERFORE provides top quality commissioning services, such as process equipment installation inspection, IO testing, dry testing, water testing, product testing, check and acceptance.Altogether, this is to ensure the good operation of individual equipment and instruments in the system and the efficient coordination between them.Likewise, our experienced engineers deliver you a trouble free pipeline or plant after careful on-site commissioning.

Services and support

In case of any problem or emergency, HYPERFORE provide on-site maintenance or remote support based on internet to ensure that you can be provided with production guarantee in the first time.

customer training

We explain to customers how the whole pipeline or the system works, and how the automation system control the relevent equipment, also the function of each component and how to disassemble and maintain them,etc.

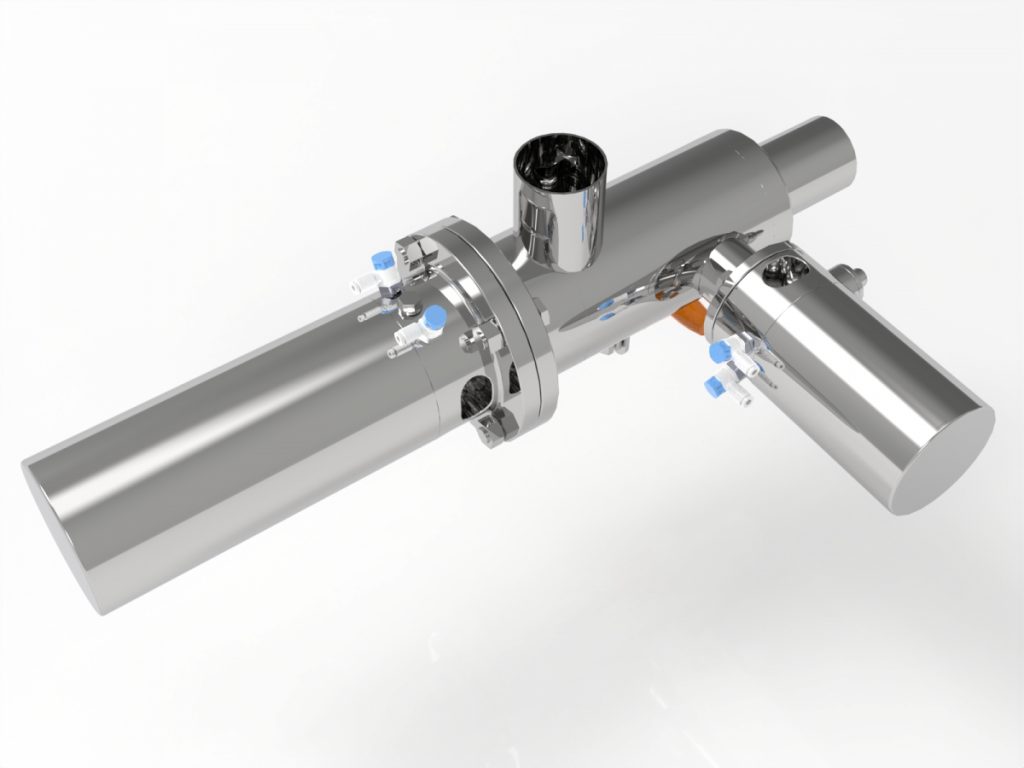

Spare parts

HYPERFORE provide customers with top quality pigging products and spare parts, for instance, pigs, sealing, piggable valves, pipes, bends, piggable elbows, swing bend, pig detectors, sensors, stainless steel special joint and flange joint ,etc.

Efficient, Reliable and Sustainable.

Frequently

Asked

Questions

Many of our customers have a lot of questions concerning the pigging system, automation control, turnkey solutions and so on. If you have similar questions ,please contact us.

Dear partners

we Appreciate your PraiseHYPERFORE successfully delivered turnkey projects to the following partners

Have questions about pigging project or pigging system case? Use the form to reach out and we will get in touch with you as soon as possible.