Remote Support Pigging Services

In case of any problem or emergency, HYPERFORE can provide remote support and maintenance pigging services based on Internet to guarantee the operation of the plant in the first time.

Authorized personnel can remotely monitor the on-site production, including pigging automation control, through mobile phones, computers, and other equipment at any time. On the other hand, operators are not limited to operating and monitoring on HMI. That is to say, they can use mobile phones or tablets at any time to view the production status, including pigging automation control, greatly reducing the fault rate in the production process. This remote accessibility is more fast and convenient than on-site service support, providing enhanced efficiency and responsiveness in managing operations.

HYPERFORE remote assistance is based on the Internet network. However, users do not need to configure wireless or limited networks separately, so long as they use the 4G card provided by the module to realize Internet connection, without any installation cost.

What Is Remote Pigging System Support Service?

Our Honour

Mobile Phone Touch Screen Monitoring

Users can monitor and operate the touch screen at any time through the mobile phone or tablet after downloading the corresponding App. Additionally, they can monitor and operate the touch screen at any time through the computer after installing related software. This seamless integration of pigging automation control enhances the accessibility and flexibility of the system, allowing users to manage operations efficiently across different devices.

Flexibility Of Remote Support Pigging Services

experience and safe

Hyperfore has 10+ years experience at providing safe, reliable support for HMI, computers and other devices.

Dedicated team

Our team is enegetic and dedicated to taking challenge,they are committed to making our customer more successful.

Spare parts

We’v been committed to providing best customer experience for partners from all trades.

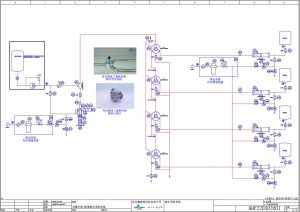

Operating Interface Of Pigging System

Intuitive picture

The process diagram displays the status of the valves and motors, as well as the status and data of the instruments in real time.

The labels of all valves, motors and instruments are convenient for operators and maintenance personnel to quickly find relevant equipment, which can be concealed during production to keep the screen clean and tidy.

The production status, steps, and production time show the current production process.

Powerful operation function

All valves, motors and their PID control can realize manual and automatic functions, which is convenient for operators to handle flexibly during operation.

Operators can flexibly select the production or cleaning mode on the production program screen.

The parameter screen can set the parameter values required according the production process, and modify different parameter values according to different processes.

Try Remote Support Pigging Services Today.

Other Pigging Services

Coming Up With Solutions

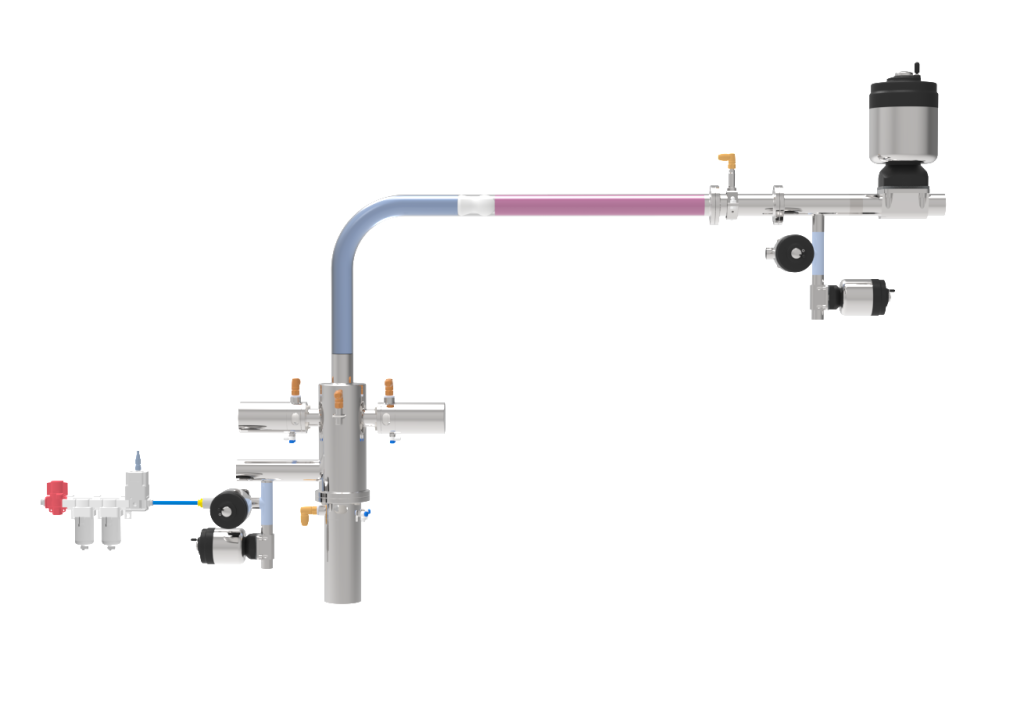

If necessary, HYPERFORE engineer will visit your site to see the actual process condition in your plant and make the most suitable solution.In addition our solution is based on cost control, consideration of safety, reasonablity and solidity.That is to say, it is a commitment to efficient production of your future pigging system.

Maintenance

HYPERFORE works out maintenance plan according to your needs and is special for you. Our engineers will visit your site according to the agreed schedule and perform important maintenance on your pigging equipment. This includes replacing repairable components, recalibrating pig detectors, and ensuring effective operation of the equipment.

Process Pipeline Test

Firstly, we test existing process and pipelines to confirm their suitability for pigging system. Secondly, we test all pipe joints, elbows, welding to identify any problem areas. Then,we record each irregularity. At last, all the defective sections of the pipeline can be replaced systematically.

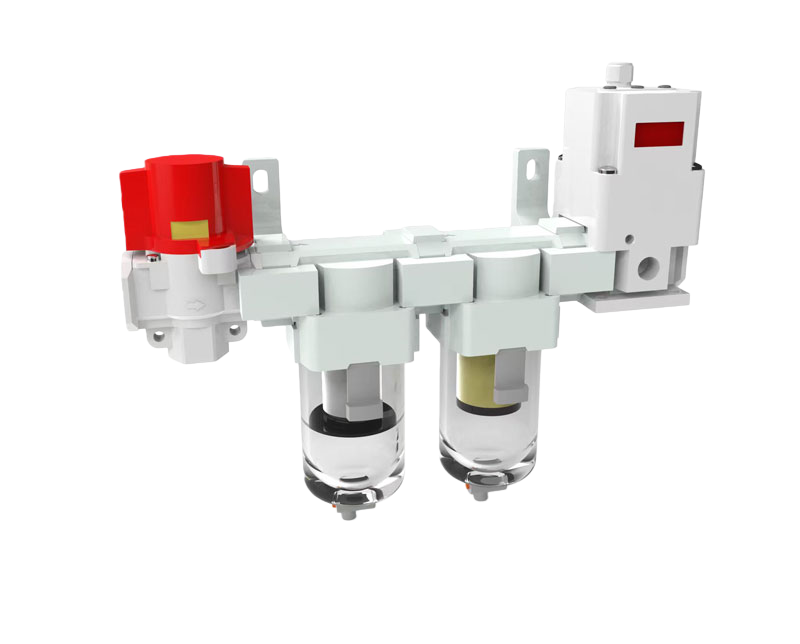

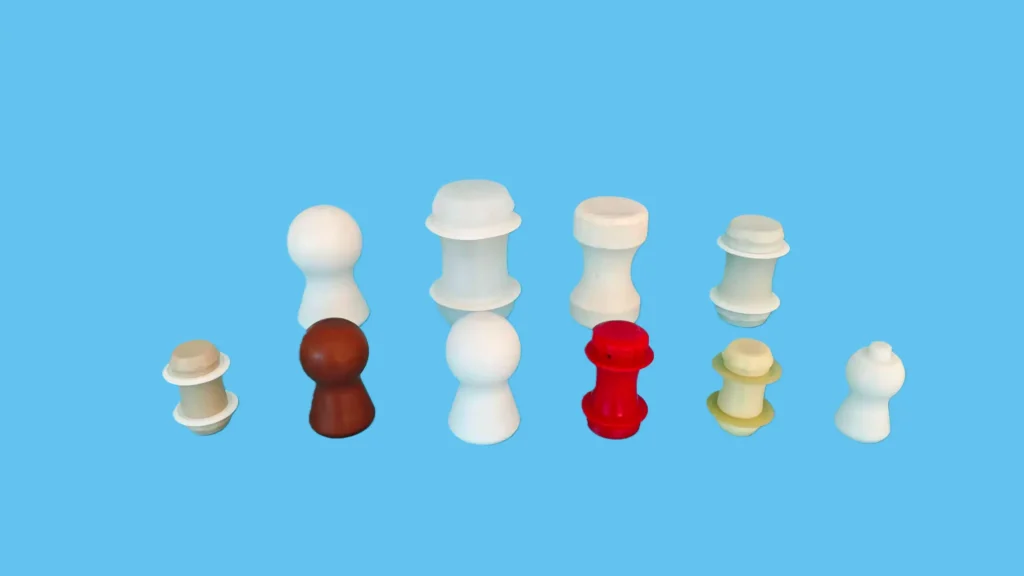

Spare Parts

Our spare parts of pigging system include several equipment .Such as launching station, receiving station, pig stopper, pigs, 3-way diverter valves, pig speed controller, pig detector, aseptic filtration equipment, cylone seperator, piggable tee, piggable elbows, etc.

Pigging System Training

Pigging system project training include the traing according to User Manual. Teaching the operator to be familiar with working principal of the system.How to open and close the relative valves through the PLC touch panel. Also train them how to adjust the propelling air pressure to the maintain the pig to travel at a constant speed along the pipeline, how to do the pipeline CIP after pigging, and so on.

Pigging Installation Guidance

Pigging installation guidance can be two choices. One is that our engineers can go to the project site. Or the guidance can be completed remotely via video call.To ensure the product recovery system can be operated well, we train the installation workers how to lay the pipeline in good order. We also tell them the proper position to install the electric panel, the correct pipe welding method, the right installation direction of the launcher and receiver, and how to choose the process connectors and sealing.

Related Products

Related Services

Related Articles

Hyperfore have many pigging system cases, pigging solutions cases, such as pigging system for food, pigging system for lithium battery slurry, pigging system for pharmaceuticals, and so on.

Contact Us

Have questions about pigging solutions? Use the form to reach out and we will be in touch with you as quickly as possible.