Hygienic (Sanitary) Pigs

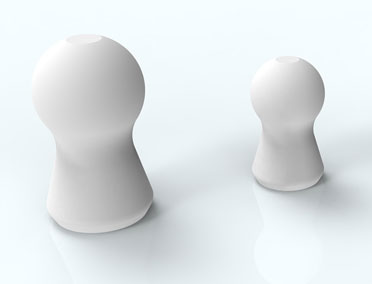

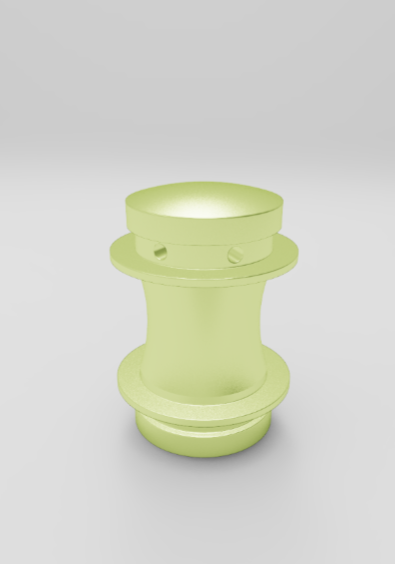

HYPERFORE sanitary pigs: one-piece pigs, lip pigs, and turbo jet pigs (pigs for powder recovery) stands out as the top choice for effectively recovering a diverse array of liquid and powder products, all of them are food grade pigs .

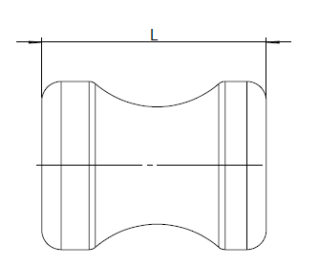

The HYPERFORE pigging products, bi-directional pigs for hygienic pipes, including the hygienic one-piece pig, are constructed from durable, wear-resistant elastic materials and have obtained FAD certification as well as a plasticizer-free certificate, ensuring they meet stringent hygiene and safety standards. The unique design of these pigging products incorporates a 360-degree fully encased aluminum alloy internal permanent magnet, providing an added layer of protection against potential accidents that might otherwise damage the magnet and cause contamination. Moreover, the one-piece pig can be easily detected using a dedicated detector.

The dimensions of the one-piece pig are slightly larger than those of the pipeline, allowing for a snug fit against the inner pipe wall, thereby achieving optimal scraping results,as demonstrated in the pigging case for dairy recovery This close conformity ensures that over 99.5% of the product can be effectively recovered during the pigging process. Additionally, the one-piece pig is designed to successfully pass through piggable equal tees, offering versatility in various pipeline configurations.

In summary, the HYPERFORE hygienic one-piece pig combines wear resistance, hygiene certification, and innovative magnet protection. Its precise fit to pipeline walls and ability to pass through equal tees make it a highly efficient solution for product recovery in hygienic applications. Furthermore, it is an environmentally responsible choice, minimizing the risk of pollution due to its robust design.

General Specifications

| PART NO. | SIZE | OD*T | WEIGHT(G) |

|---|---|---|---|

| DCPMB00D025A | DN25 | Φ29*1.5 | 28 |

| DCPMB00D040A | DN40 | Φ41*1.5 | 84.4 |

| DCPMB00D050A | DN50 | Φ53*1.5 | 184.8 |

| DCPMB00D065A | DN65 | Φ70*2.0 | 394.7 |

| DCPMB00D080A | DN80 | Φ85*2.0 | 695 |

| DCPMB00D100A | DN100 | Φ104*2.0 | 1322.8 |

| DCPMB00D125A | DN125 | Φ129*2.0 | |

| DCPMB00D150A | DN150 | Φ154*2.0 | |

| PART NO. | SIZE | OD*T | WEIGHT(G) |

|---|---|---|---|

| DCPMB00T025A | 1″ | Φ25.4*1.5 | 18.66 |

| DCPMB00T032A | 1.25″ | Φ31.8*1.5 | 37.5 |

| DCPMB00T038A | 1.5″ | Φ38.1*1.5 | 66.6 |

| DCPMB00T051A | 2″ | Φ50.8*1.5 | 160 |

| DCPMB00T064A | 2.5″ | Φ63.5*2.0 | 300 |

| DCPMB00T076A | 3″ | Φ76.1*2.0 | 480 |

| DCPMB00T089A | 3.5″ | Φ88.9*2.0 | 821.4 |

| DCPMB00T101A | 4″ | Φ101.6*2.0 | 1237.8 |

| DCPMB00T127A | 5″ | Φ127*2.0 | |

| DCPMB00T152A | 6″ | Φ152.4*2.0 |

The tables above are to display the detailed technical data of the one-piece scraper.

WEAR RESISTING & EFFECTIVE

Suitable for liquid products with particles or frictional products

DETECTABLE

Hyperfore hygienic pigs can be easily detected by our pig dectector

SAFE AND GUARANTEED

Hyperfore sanitary pig has received FAD Certificate and Plasticizer Free Certificate

ONLINE CLEANING

Able to be cleaned all together with the pipeline by CIP or SIP

LONG SERVICE LIFE

The pig can run about 28km within its service period

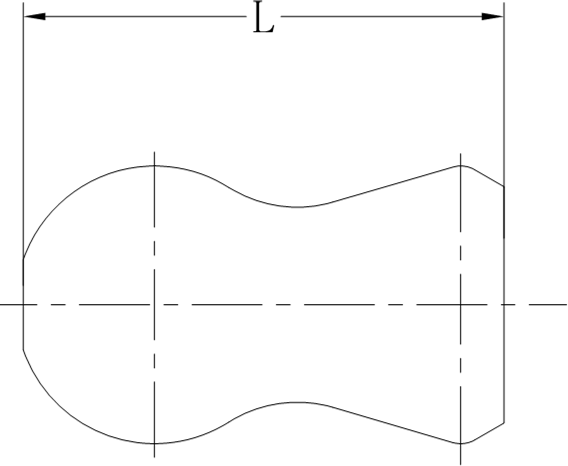

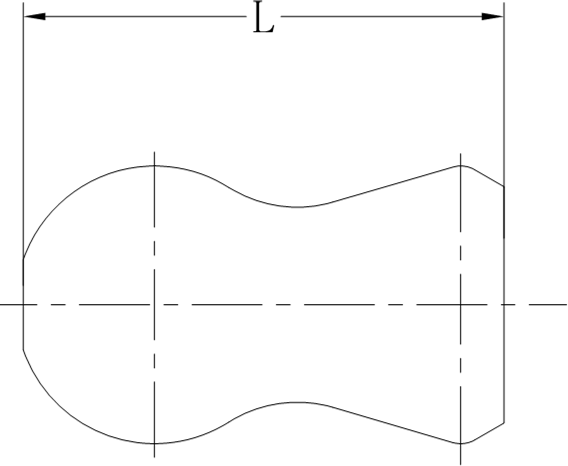

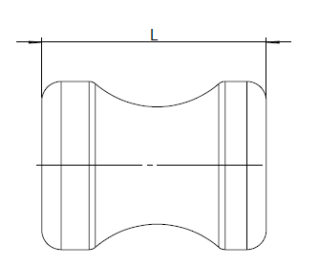

The dual-shoulder hygienic pig, also one of the hygienic bi-directional pigs, with its symmetrical design, features a relatively soft material and this symmetrical shape, ensuring a snug fit to the inner walls of pipelines, thus achieving optimal pigging efficiency. Compared to conventional pigging devices, it offers superior pigging performance, resulting in significantly lower product residue on the pipeline walls and improved product recovery rates, thereby enhancing pigging ROI. Of course, it requires a relatively higher driving force to propel the pig through the pipeline. It is available in various materials such as VMQ, EPDM, FKM, and more, making it suitable for pigging applications in the food, pharmaceutical, and other hygienic fluid product industries. Customization is also available to meet specific requirements.

The symmetrical design of the dual-shoulder hygienic pig allows it to conform closely to the inner pipeline walls due to its relatively pliable material, delivering optimal pigging performance. In comparison to standard sanitary pigs, it ensures more effective removal of residual product from the pipeline, thereby enhancing product recovery rates. However, it does require a higher driving force to propel the pigging device within the pipeline. This device is crafted from various materials such as VMQ, EPDM, FKM, and others, making it versatile for pigging application in the food, pharmaceutical, and other hygienic fluid product industries. Customization options are available to tailor the device to specific needs.

| PART NO. | SIZE | OD*T | L(MM) | WEIGHT/G |

|---|---|---|---|---|

| DCPLXDXD025A | DN25 | Φ29*1.5 | ||

| DCPLXDXD040A | DN40 | Φ41*1.5 | ||

| DCPLXDXD050A | DN50 | Φ53*1.5 | ||

| DCPLXDXD065A | DN65 | Φ70*2.0 | ||

| DCPLXDXD080A | DN80 | Φ85*2.0 | ||

| DCPLXDXD100A | DN100 | Φ104*2.0 | ||

| DCPLXDXD125A | DN125 | Φ129*2.0 | ||

| DCPLXDXD150A | DN150 | Φ154*2.0 |

| Part Nr. | SIZE | OD*T | L(MM) | WEIGHT/G |

|---|---|---|---|---|

| DCPLXDXT025A | 1″ | Φ25.4*1.5 | ||

| DCPLXDXT032A | 1.25″ | Φ31.8*1.5 | 25 | |

| DCPLXDXT038A | 1.5″ | Φ38.1*1.5 | 34.2 | |

| DCPLXDXT051A | 2″ | Φ50.8*1.5 | 43.3 | |

| DCPLXDXT064A | 2.5″ | Φ63.5*2.0 | 50.3 | |

| DCPLXDXT076A | 3″ | Φ76.1*2.0 | 65.5 | |

| DCPLXDXT089A | 3.5″ | Φ88.9*2.0 | 75.5 | |

| DCPLXDXT102A | 4″ | Φ101.6*2.0 | 84.8 | |

| DCPLXDXT127A | 5″ | Φ127*2.0 | ||

| DCPLXDXT152A | 6″ | Φ152.4*2.0 | ||

The tables above are to display the detailed technical data of the one-piece lip scraper.

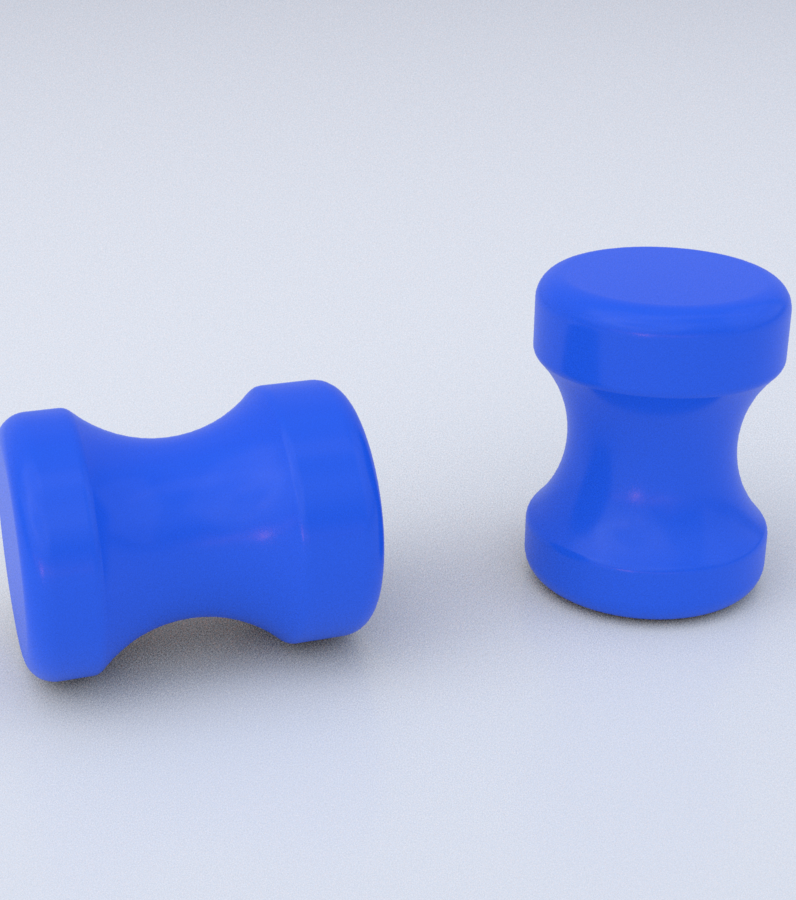

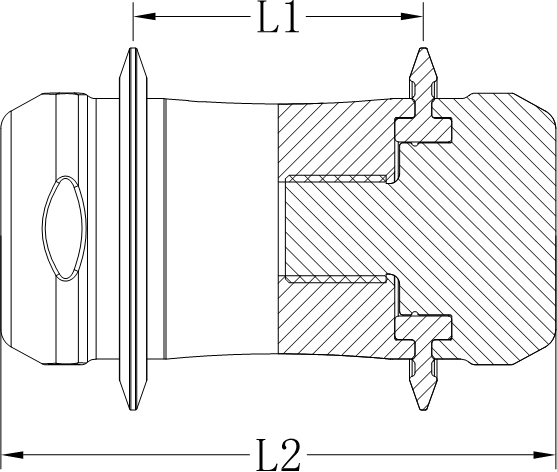

The HYPERFORE dismountable lip pig, is a. kind of bi-directional pig, designed with hygiene in mind, is expertly crafted using sanitary materials and features soft, elastic lip-shaped seals. These specially engineered lip-shaped seals not only extend the pig’s lifespan but also make it exceptionally well-suited for products containing particles, as evident in various pigging cases. One of the key advantages of this pig is its replaceable lip-shaped seals, which can be individually swapped out, ensuring cost-effective maintenance.

Furthermore, the dismountable pig, known for its exceptional versatility, effortlessly navigates through elbows with bending radii of 1.5D, 3D, and 5D, making it a perfect fit for a wide array of pipeline configurations. This innovative design not only enhances the pig’s longevity but also guarantees its adaptability to diverse product and pipeline requirements, making it an ideal choice for hygienic applications and various pigging solutions.

Material: lip (VMQ, FKM, EPDM) body (PP, PFA)

The dismountable version has an economical operating cost. The lip seals can be replaced according to their wear and tear and adapted according to the process fluid

The design of our scrapers offers a low friction coefficient while allowing maximum recovery of the product.The required pushing pressure is reduced.

Material:

Pig :

– Polypropylene.

– PFA, on request

Lip seal :

– VMQ

– FKM

– On request:

FFKM

FKM antacid

| PART NO. | SIZE | OD*T | L1 | L2 | WEIGHT/G |

|---|---|---|---|---|---|

| DCPMS01D025A | DN25 | Φ29*1.5 | |||

| DCPMS01D040A | DN40 | Φ41*1.5 | |||

| DCPMS01D050A | DN50 | Φ53*1.5 | |||

| DCPMS01D065A | DN65 | Φ70*2.0 | |||

| DCPMS01D080A | DN80 | Φ85*2.0 | |||

| DCPMS01D100A | DN100 | Φ104*2.0 | |||

| DCPMS01D125A | DN125 | Φ129*2.0 | |||

| DCPMS01D150A | DN150 | Φ154*2.0 |

| Part Nr. | SIZE | OD*T | L1 | L2 | WEIGHT/G |

|---|---|---|---|---|---|

| DCPMS01T025A | 1″ | Φ25.4*1.5 | |||

| DCPMS01T032A | 1.25″ | Φ31.8*1.5 | 25 | 50 | |

| DCPMS01T038A | 1.5″ | Φ38.1*1.5 | 34.2 | 61.4 | 47.4 |

| DCPMS01T051A | 2″ | Φ50.8*1.5 | 43.3 | 82.8 | 113.4 |

| DCPMS01T064A | 2.5″ | Φ63.5*2.0 | 50.3 | 99.8 | 195.4 |

| DCPMS01T076A | 3″ | Φ76.1*2.0 | 65.5 | 117.5 | 348.6 |

| DCPMS01T089A | 3.5″ | Φ88.9*2.0 | 75.5 | 137.5 | 607.8 |

| DCPMS01T101A | 4″ | Φ101.6*2.0 | 84.8 | 156.3 | 854.2 |

| DCPMS01T127A | 5″ | Φ127*2.0 | |||

| DCPMS01T152A | 6″ | Φ152.4*2.0 | |||

The tables above are to display the detailed technical data of the dismantable lip scraper.

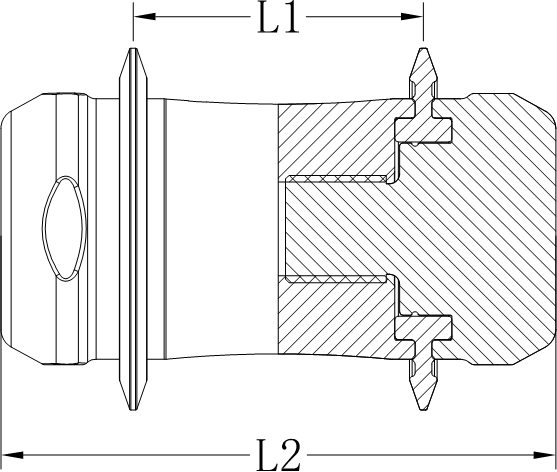

Turbo Jet Jetting Pipeline Pig:

The Jetting Pipeline Pig, also called pigs for powder recovery, it is a kind of bi-directional pig, features six gas jet nozzles at its front end. As it traverses through the pipeline, it expels N2 from the jetting end to dislodge any powder adhering to the inner pipe walls. The airborne particles are then conveyed to the end of the pipe, achieving a more effective cleaning process. Following the pipe cleaning pig, it reduces the time and manpower required for subsequent cleaning.

- It complies with ISO 1.5″ to ISO 4″ and DIN 11850 series DN40 to DN150 standards.

- Constructed from highly abrasion-resistant, food-grade cleaning materials.

- Customization available for other pipeline standard sizes.

- Customizable sealing materials include EPDM/FKM/VMQ, among others.

- Can be integrated into fully automated systems.

Powders are widely employed in various industries, including pharmaceuticals, food, metallurgy, chemicals, plastics, coatings, and construction, playing a pivotal role. They serve as essential components in the production of food, pharmaceuticals, fillers, functional materials, drugs, biomaterials, and processing materials. Especially in the pharmaceutical and food manufacturing sectors, powdered formulations represent a common pharmaceutical dosage form, utilized for the production of tablets, capsules, powders, and oral liquid preparations, among other formulations. In the food industry, they are also found in the form of products like milk powder, vegetable fat powder, starch, flour, and more.

The implementation of a sanitary pigging system helps achieve significant cost savings. Sanitary pigging systems play a crucial role in preserving product quality and safety while optimizing efficiency in these diverse industries.

Largely improving production and reducing cost

Common Questions

Contact Us

Have questions or need help? Use the form to reach out and we will be in touch with you as quickly as possible.