Pigging Application in Different Industries

Pigging Application Introduction

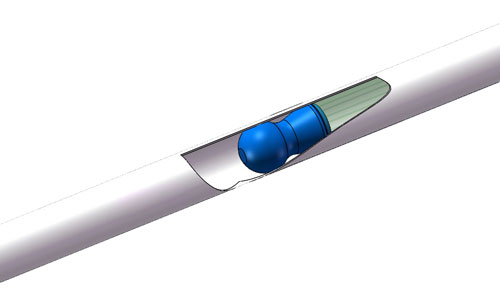

Pigging is a kind of operation that utilizes specialized one or two pigs to clean the liquid production line and recover valuable liquid products. Pigging is employed across a wide range of industries, including, but not limited to food, drinks, sauces, chocolate, dairy, paints and coatings, pharmaceuticals and chemicals.

Advantages of Pigging

- The key benefits of using pigging across different industries are extensive:

- Improving pipeline hygiene and cleanliness.

- Increasing product recovery and reduced waste.

- Minimizing the usage of CIP cleaning agents and water

- Enhancing operational efficiency and reduced downtime.

- Environmental benefits through reduced water and chemical usage.

- Cost savings in maintenance and cleaning.

- The purpose of this article is to explore the diverse applications of pigging in different sectors.

Pigging Application in Food and Beverage Industry

Food safety is the primary challenge facing the food and beverage industry. Various toxins, harmful substances and substandard products pose a threat to human health, and consumers are increasingly concerned about food quality and safety.

The cost pressure on the food and beverage industry is increasing day by day. Fluctuations in raw material prices, rising labor costs, and increased transportation expenses directly affect the profitability of enterprises. At the same time, consumers also have certain requirements for product prices. How to reduce costs and improve business efficiency based on ensuring food safety is an urgent problem to be solved in this industry.

Advanced pigging technology can ensure the manufacturers stay ahead of the regulations and prevent safety risks. Hyperfore sanitary pigging systems are suitable for food sectors. The material is SS316L, the inside polishing and outside polishing match food equipment compliance. the internal design of the launcher and receiver features low residue and hygiene. Hyperfore sanitary pigs are also right option, the pigs are reliable and long-wearing, they are made of food-approved materials and pass FDA certification.

Food and beverage are valuable product. Hyperfore sanitary pigging systems plays an important role in product recovery. Our pigging process recovers over 99% of the residue for reuse or resale. And the return on investment is fast, normal customer can get back the investment in about 6 months.

Pigging Application in the Pharmaceutical

The pharmaceutical industry is a special sector, concerning people’s life quality. Therefore, the state has strong regulatory oversight. For the long-term development of enterprises, they must always comply with national policies and operate legally and compliantly.

Facing globalization, the international competition in the pharmaceutical industry is intensifying. Pharmaceutical manufacturers have also struggled to solve several ‘bottleneck’ technology problems to survive in the fierce international competitiveness.

In the face of the above pain points, what pharmaceuticals manufacturers need is to innovate pharmaceutical production equipment to help ensure safe drug production; and comply with national policies and operate legally to safeguard drug safety.”

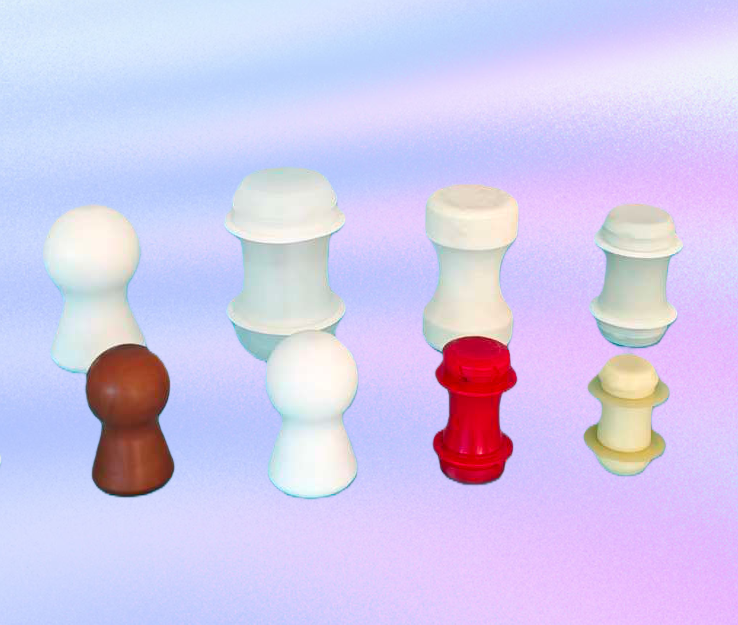

Hyperfore aseptic pigging system are specially designed for aseptic operation, compatible with drug production safety regulations. It is automatic, highly efficient, minimizing human errors and pollution risks. Hyperfore sterile pigging system consists of an aseptic launching station, an aseptic receiving station and a sterile pig. The stations eliminate dead space for cleaning, minimizing cross-contamination risks, safeguarding the drug production safety. The pigs are made of drug-approved materials, compliant with various pharmaceutical product formulations.

Furthermore, pigging also significantly reduces product waste by recovering large amount of valuable residue drugs in the pipeline. Over 99% of the residue products can be recovered, our aseptic pigging technology shortens pipeline cleaning time, boosting overall production efficiency.

Pigging in Paints and Coating Industries

Looking back at the past year, the global economic situation has been unstable, with a continuous market downturn. Against this backdrop, the paints and coating industry is also facing multiple challenges such as fluctuating market demand and unstable raw material prices. The recent economic downturn has even led to significant job cuts across the industry. However, survival and development is still the key priority of an enterprise.

The most important functions of pigging system are reducing cost and improving profits.

Paints and coatings are sticky, they are likely to adhere to the inner wall of the pipeline after production. Normal pigging system may not get a satisfactory cleaning result. Hyperfore double-pig system is specially designed for paint and coating pipeline. during operation, a short section of solvent is sandwiched between the two pigs. The solvent can dissolve the substance stuck to the pipeline interior, making the pigging process easier. Hyperfore double pig system is automatic. It is safe and effective, minimizing the usage of human labor. It can benefit paints and coating manufacturers by lessening cost, reducing waste, enhancing yields, improving efficiency and maintaining sustainable development.

Pigging in cosmetics and home-care agents

Toner, lotion, cream, facial water, cleaner, shampoo, toothpaste, detergent and so on, these liquid products tend to be pricey in the market. During production, they are pumped into pipes and transferred in pipelines. However, the waste of products, water and resources during pipeline cleaning is the major headache of the manufacturers.

After pigging system is introduced into these sectors, manufacturers find pipeline pigs effective equipment to clean and recover products from processing line. Hyperfore sanitary pigging system is a valuable tool for cosmetics and home-care agents manufacturers looking to optimize their production processes, reduce waste, and maintain high standards of hygiene.

Pigging in chemical industries

During chemical processing, leakage and explosion proof is of the premium importance.

Some kind of chemical is explosive, and some kind of chemical is dangerous, the leakage may cause safety accident. Pigging system applied to chemical sectors should be low residue and allow no chemical leakage. Hyperfore non-sanitary pigging system features a professional design, launching stations and receiving stations have passed strict pressure and sealing tests. Therefore, the liquid products will not leak from the inner connections like clamps or flanges, ensuring chemical production safety.

Conclusion

Pigging is a valuable tool in various industries. Hyperfore continues to develop the pigging technology to meet the rising industry challenges. We are dedicated to developing pigging technology that addresses the needs of various industries, ensuring future applications are more efficient and intelligently designed.

FAQ

Related Articles

Hello,

I’m Richard Gan, General Manager at Beijing Hyperfore Technology Company Ltd.

Since our founding in 2005, we have accumulated almost 10 years of focused experience in the Chinese market, specializing in the design and delivery of advanced sanitary pigging systems and integrated solutions.

If you have any questions, please feel free to contact us. We are pleased to provide you best products and services.

Email: wenbo.gan@hyperfore.cn WeChat: hyperfore2005

WhatsApp: +86 18910216756

Let us know how we can help you!

To improve the profits, reduce waste and improve competitiveness of your business through bi-directional pigging application, contact Hyperfore today!