What Is a Pipeline Pig?

Table of Contents

What Is Pigging in Food and Dairy Pipelines?

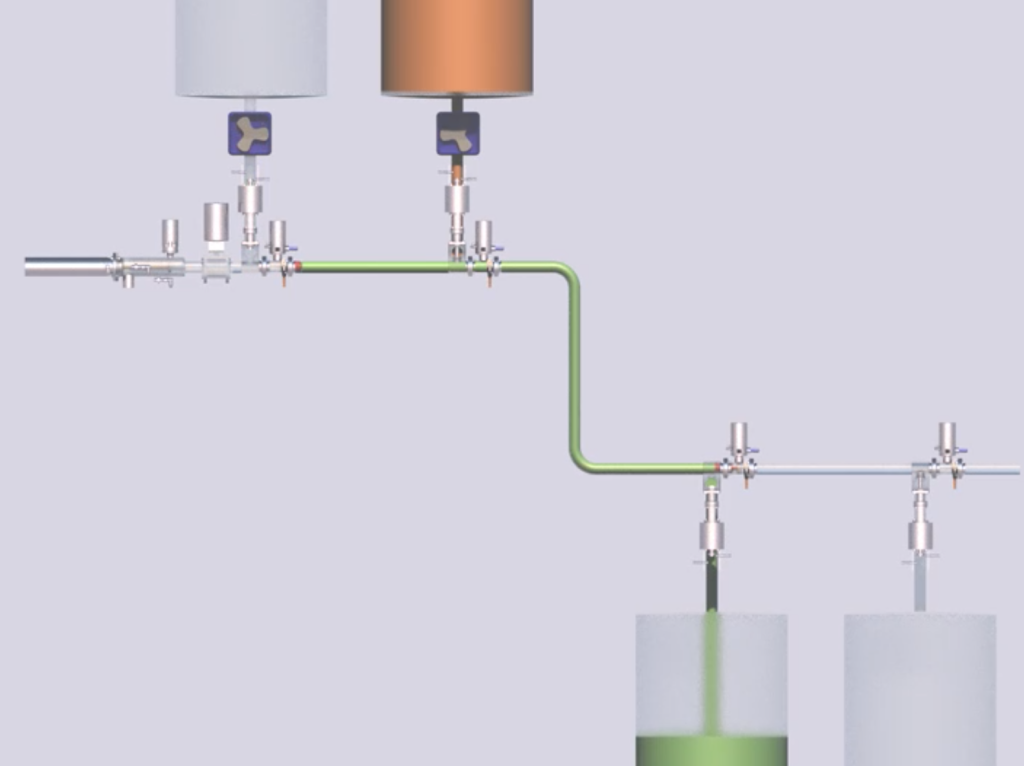

In the food and dairy processing industries, liquid products are pumped to the pipelines by Centrifugal pump, rotor pump, or even screw pump. It depends on the viscosity of the liquid to decide what kind of pumps to be used.Sanitary pigging is cost-effective way to clean the inner parts of pipes, protect the pipelines, recover valuable liquid food products and raise yielding. Hyperfore sanitary pigging system normally include three parts: a launcher, a receiver and a pig.

Purpose of Pipeline Pigging

Hygienic pipeline pigging play the role for pipeline cleaning.It helps the pipework to be smooth working and functional. For some pipelines, because the liquid is very sticky, after the liquid delivery again and again, the inner wall of the pipes can become narrower and narrower over time. The pigging system can clean the inner wall of the pipeline, and clear the sticky medium, as a result, the inside of the pipe is smooth and the inner wall is smooth.

Pipeline pigging is a superb method to enhance the yielding and cut down waste. As we all known, for food and other valuable liquid processing industries, CIP is implemented to clean the pipes and wash away the residue products in the pipelines. But a significant amount of valuable product is wasted, and the cost of water, detergent and waste water treatment is large. A pigging system can recover almost all the residue product in the pipelines, so that waste is largely reduced, profit is raised.

Pipeline pigging works to protect the pipeline system. When the inner wall of the pipeline is filled with viscous products, after a long time, the pipeline may be corroded and cracks may appear.

Sanitary Pipeline pigging can effectively avoid the cross-contamination, and raise the product quality. The spoiled substance remaining in the gaps of the inner wall of the pipelines will pollute the new product and impair the quality of the whole batch of product, and this is called cross-contamination, pigging can effectively avoid this situation.

In summary, Hyperfore pipeline pigging can clean pipeline garbage, protect pipelines, and extend pipeline life,avoid cross-contamination, reduce product lost, improve productivity and profit. These are the purposes of using pipeline pigging.

How Does Pipeline Pigging Work?

The Following Is To Illustrate How Hyperfore Pipeline Pigging Process Works

The discharging valve is open, the product begins to transfer. When one batch of product transporting finishes, the discharging valve is closed. The feeding valve is open. Under the control of automated procedures,the gear lever is retracted, The push rod stretch out, the sanitary pig is pushed from the launching station to the pipeline. The bi-directional pig is driven by clean compressed air and travels along the pipe. The pig speed regulator can regulate the air pressure, ensure the pig to run at even speed. The pig closely fits the inner wall of the pipe, when it is going, the pig scrapes the inner pipeline wall, so that the residue product is pushed forward to the destination tank. When the pig arrives at the receiving station, the pig tracking unit can detect the pig and the light will turn on. This procedure means the product has been recovered to the destination tank and the pig will return to the launching station.The feeding valve is closed, the air feeding valve beside the receiving station is open. The draining valves are open, The pig is driven by the clean compressed air, and it travels from the receiving station to the launching station.The pig tracking unit detects the pig, the light turns on. In the launching station, the gear lever stretches out, the pig is locked in the launching station. This is a complete cleaning process When CIP is implementing, the main pipeline is open and the branch pipeline is opened intermittently. The pig stays in the launching station to be cleaned with the pipelines.

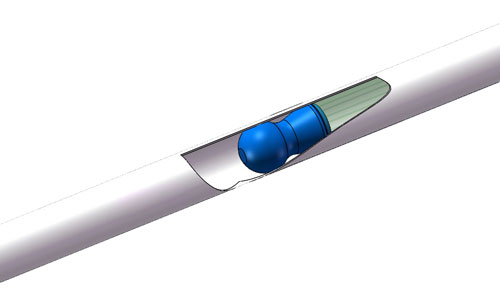

What Is a Pipeline Pig?

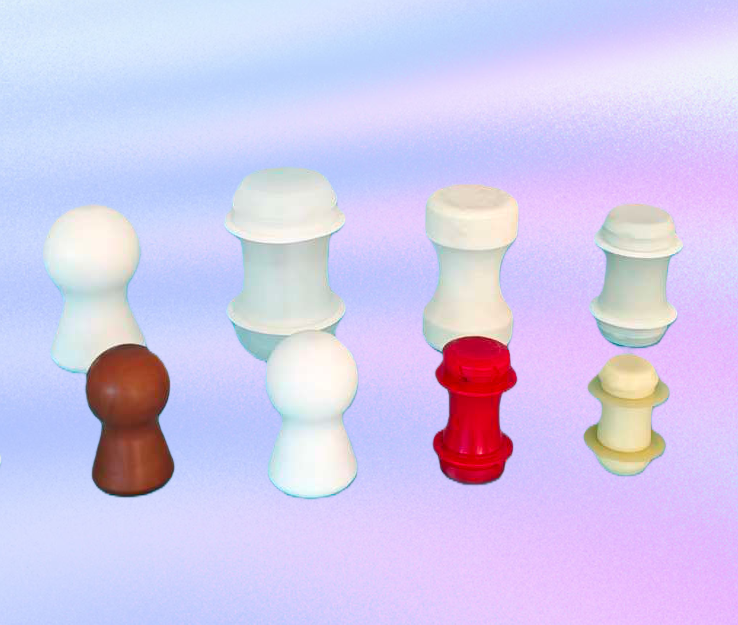

The main function of our pipeline pig is to scrap off the residue product(food , dairy and other sanitary product) from the inner wall of the pipelines and push them to the pipe outlet for storage or filling. Hyperfore pipeline pig is an elastic projectile, it is made of various kinds of materials, such as VMQ, EPDM, FKM, NBR and so on. Hyperfore pigs are customized according to the products chemical properties and production process. Because the pig has to fit tightly into the inner wall of the pipe, the diameter of the pig has to be a little bigger than the inner diameter of the pipe. The design of the pig is for effectively scraping off the product and recovering it.

Types Of Pipeline Pigs

- One-Piece Pig

Hyperfore’s one-piece pig is suitable for pigging food, dairy, chocolate, shampoo and other sanitary products. It adopts an integrated design and is made of elastic materials that meet sanitary requirements and have minimal wear. It has a thin waist and is suitable for passing through elbows with a minimum bending radius of 1.5D for piggable pipelines; the one-piece pig is also used for passing reducing tees. The permanent magnets inside the pig are designed to be covered and encapsulated. Even if there is an accident, the permanent magnets will not make pollution.

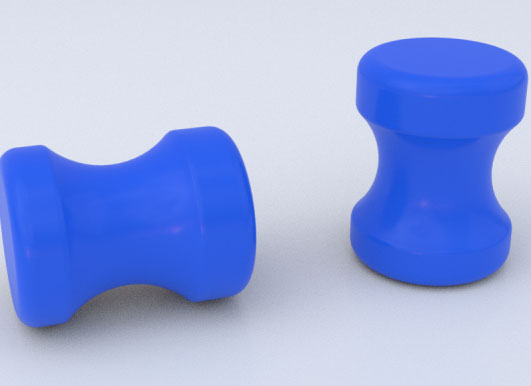

- Double- shoulder Pig

Hyperfore’s one-piece pig is suitable for products with high viscosity like syrup, glue, cosmetics and so on. Double shoulder pig adopts symmetrical design. The pig has a larger surface area in contact with the inner wall of the pipe,and the scraping effect is much better. But it requires greater pushing pressure to make it move along the pipe.

- Replaceable Lip Pig

The Hyperfore Lip pig is suitable for liquid products with particles, such as lithium ion battery slurry, grainy jam, etc. The pig is made of multiple sanitary grade materials and it has soft elastic lips. The unique design of the lips makes the pig has a longer service life and is more wear-resistant. Lips can be replaced individually.

- Pig For Powder Pigging(Turbo Jet Pig)

- Hyperfore Turbo jet pig is suitable for powder product pigging and recovery, such as, milk powder, seasoning powder, chemical powder, cosmetics powder, collagen powder so on.

- There are six gas injection ports at the front end of the jet pig.

- During the process of traveling in the pipeline, N2 can be ejected from the injection end to loosen the powder attached to the pipe wall, and the air flow is used to transport the floating powder to the end to achieve a better cleaning effect.

- After pigging, it can reduce the time and manpower required for further cleaning.

How Is the Pig Movement Monitored?

Hyperfore pig is tracked by a Pig Detecting Unit when it runs along the pipeline. There is a permanent magnet inside the pig, which is firmly wrapped in a metal box. Magnets produce magnetic fields. Hyperfore pigs can be monitored by the Pig Tracking Unit. The detection unit detects the magnetic field of the magnet through the sensor. The Magnetic induction distance is 60mm. When it detects the pig, the light gets on, and the sensor sends signals to PLC.

Hyperfore pigs can also be detected by Pig Detecting Pen. When the pig gets stuck somewhere along the pipeline, and operators can hold the Pig Detecting Pen to find its position.

Conclusion

A pipeline pig is really an indispensable component of a pigging system and the pigging process. Hyperfore pipeline pigs contains for types, the one-piece pig is normally applied to recover beverage, mayonnaise and other liquid food products. The double-should pig is applied to sticky food, pharmaceutical products.The lip pigs are suitable for liquid products with particles ,and the Turbo jet pig is suitable for powder products, like milk powder, cosmetics powder,collagen powder and so on.

Related Articles

FAQ

Contac us

For further inquiries about Hyperfore pigging systems, their purposes, and benefits, please reach out to us. Our professional team is dedicated to providing comprehensive answers and insights.