Case Of a Pigging System For Curry Sauce Recovery

Case Of a Pigging System For Curry Sauce Recovery

Table of Contents

Case Study- Mida’s Food

Hyerfore designed a customized pigging system for Mida’s Food in China to recycle residual curry sauce from pipes back to the filling machine for easy canning and sales. Implementing related automation and installation projects at the client’s factory, this automatic pigging application with a 3-way diverter valve offered high return on investment, improved production efficiency through automation, saved costs and boosted profits for the client’s factory.

Summary

Hyperfore has created a fully automated 2.5-inch hygienic pigging system for China Mida’s two production lines and provided comprehensive technical support during installation and commissioning. This innovative solution is renowned for its high and fast ROI, effectively reducing curry sauce wastage and boosting production. Furthermore, it accelerates the transition process on the client’s production line, improving operational efficiency. By conserving energy and resources, Hyperfore’s pigging solution actively contributes to the company’s competitiveness and commitment to environmental sustainability. This technology not only reduces costs but also aligns with our client’s green initiatives, promoting a more sustainable approach to curry sauce production.

About Mida’s Food

Miaoduo Food is a modern private science and technology enterprise established by Guangzhou Kangying Food Co., Ltd. in China, specializing in the production of curry powder, curry paste, salad dressing, jam, tomato sauce, seasoning sauce and other condiments. It has the brands of “Miaoduo”, “DAK DAK” and “Sui Cheng”.

Our Customer’s Requirements

Miaoduo Food Co., Ltd., a renowned domestic salad dressing manufacturer, is seeking a solution to recover residual materials in their pipelines. After thorough comparisons, they approached Hyperfore to inquire about pigging technology and explore a potential collaboration.

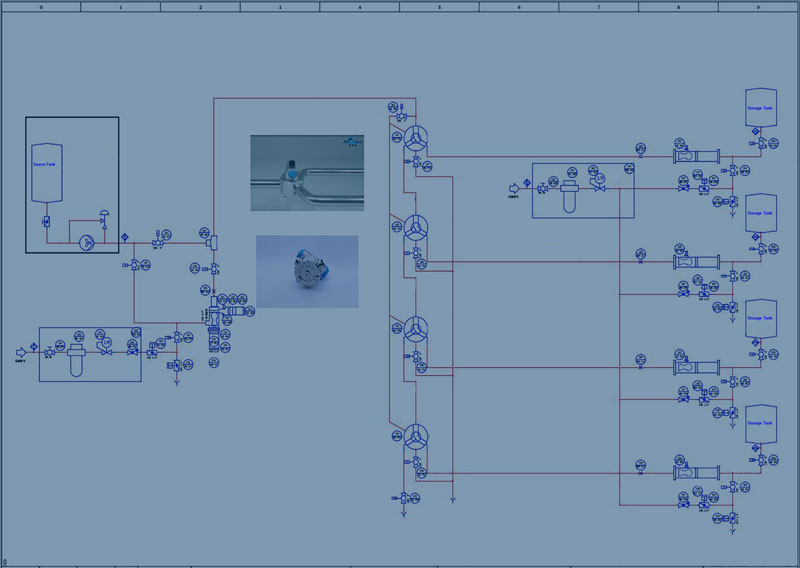

The client’s production workshop comprises two production lines, with each line having four filling machines. The product is pumped into the pipeline and then directed to the filling machines through the pipeline. The pipeline dimensions are 2.5 inches, and each pipeline is over twenty meters long. The client’s objective is to minimize waste of product material-curry sauce within these pipelines.

Our collaboration aims to implement an efficient pigging system that can effectively recover and utilize the residual materials in the pipelines, optimizing the production process for Miaoduo Food.

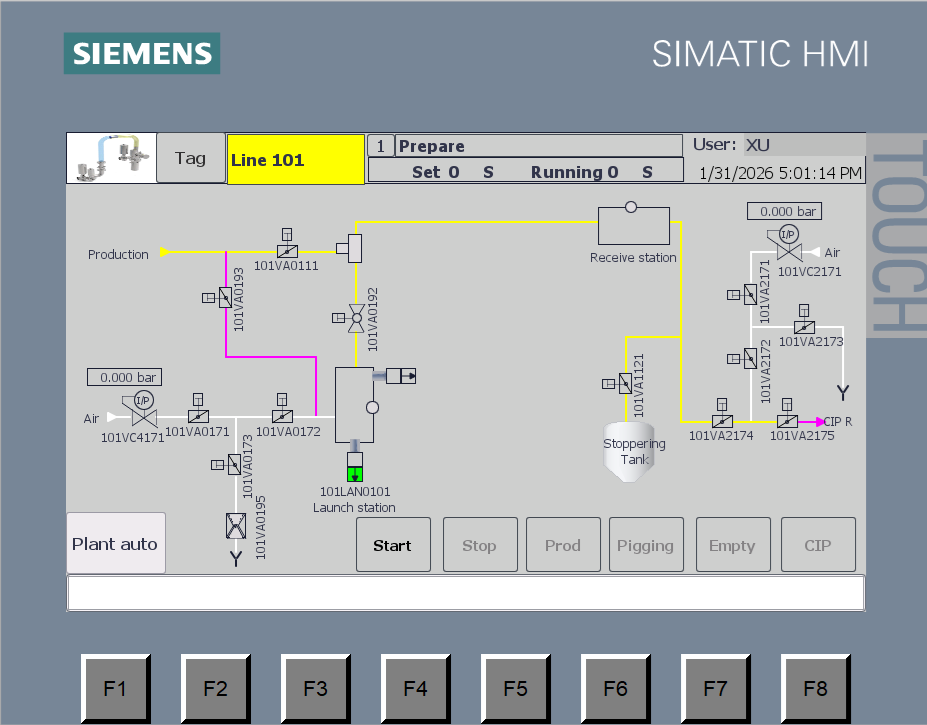

Hyperfore’s Sanitary Pigging Solution

Hyperfore tailored an automated pigging system solution for our client, Miaoduo Food. The feed pump is situated on a bypass pipeline next to the main pipeline, with the pig launching station installed a few meters ahead on the main pipeline. Behind the launching station, a piggable three-way diverter valve is installed to facilitate sequential switching during pigging on the two different pipelines. When cleaning the first pipeline, the three-way valve connects the launching station to the first pipeline, and similarly, when cleaning the second pipeline, the three-way valve connects the launching station to the second pipeline. Each main pipeline’s bypass is connected to 3-4 filling machines, allowing efficient recovery of salad dressing to their respective target filling machines, streamlining the production process.

Given the relatively disorderly installation of pipelines in the client’s factory and limited space, we made every effort to optimize the use of available space, ensuring a neat and organized layout during installation.

The entire installation and commissioning process took 23 days. Upon completion, the pipelines underwent water flushing for pigging testing, exhibiting excellent results. Subsequent product testing further validated the effectiveness of the product recovery system.

The system operates with four recovery cycles per day, reclaiming approximately 85 liters per cycle, totaling 340 liters daily, equivalent to approximately 0.5 tons. The successful implementation of the pigging system shows that food products recovery by pigging has not only streamlined the production process for Miaoduo Food, but also significantly reduced product wastage, showcasing the efficiency and reliability of our customized pigging solution. The collaborative effort in overcoming the challenges of complex pipeline layouts and spatial constraints has resulted in a successful project outcome, meeting and exceeding the client’s expectations for improved efficiency and resource utilization.

The Customer’s Feedback

The customer has expressed overwhelmingly positive feedback regarding our sanitary pigging system and pigging products and the associated installation and commissioning services. They highlighted the tailored approach we took in designing the automated pigging system, emphasizing its effectiveness in recovering residual materials within their complex pipeline infrastructure.

The successful implementation of our product recovery system design was particularly evident in a recent project involving Hotpot Sauce Recovery. In this case, the client specifically commended the strategic placement of the feed pump on the bypass pipeline and the pig launching station on the main pipeline. This design, coupled with the implementation of piggable three-way diverter valves, seamlessly facilitated the transition between the two production lines during the pigging process.

Hyperfore pigging system’s flexibility and efficiency not only met but exceeded the client’s expectations. The unique challenges posed by the curry sauce recovery process were effectively addressed through our innovative design and meticulous planning.

The 23-day installation and commissioning period, completed in a timely manner, further contributed to the positive feedback. The system underwent rigorous testing, including water flushing for pigging and subsequent product testing, which demonstrated exceptional performance and reliability. We also supplied remote support pigging services.

The customer particularly highlighted the daily recovery cycles, with each cycle reclaiming approximately 85 liters of product. This efficiency translated to a significant reduction in product wastage, amounting to an impressive daily total of 340 liters or approximately 0.5 tons. The successful implementation of the pigging system not only streamlined their production process but also resulted in tangible resource savings, aligning seamlessly with the client’s sustainability goals.

The client’s acknowledgment of the substantial product recovery and resource savings achieved through Hyperfore pigging solution and engineering underscores its effectiveness in optimizing their operational efficiency and environmental impact. This success story serves as a testament to our commitment to delivering tailored and effective solutions that address the unique challenges faced by our clients, emphasizing both practicality and sustainability in industrial processes.

About Author: Hyperfore

Beijjing Hyperfore Technology Co.,Ltd. was founded in 2005, covers an area of 2400 square meters. We are engaged in the automation, project process design, production line electrical and mechanical installation, mechanical equipment research and manufacturing, pigging solutions. Our products and services cover sanitary pigging system, aseptic pigging system, manual pigging system, piggable 3-way diverter valves, pipeline pigs(scrapers), and other pigging products. Our customers spread across various industries around the world, including dairy, sauce, beverage, pharmaceutical, chemical and so on.

Related Products

Hyperfore supply sanitary pigging system, aseptic pigging system, manual pigging system, launching station, receiving station, bi-directional pipeline pigs, pigging products, pigging system automation, pigging system installation, pigging system services, etc..

Related Articles

If you are interested in the application of sanitary product recovery systems, and the relevant technical information, please refer to the following articals.

Related Cases

Hyperfore’s extensive portfolio showcases a diverse range of pigging system solutions, including notable cases in various industries such as food, lithium battery slurry, Chinese medicine (pharmaceuticals), and more. When considering how to choose a pigging system, it’s crucial to tailor the selection process to the specific needs of each industry.