Custom Dual-Pig System For Oxidation Prevention & Viscous Products

How Does a Dual-Pig System Prevent Oxidation?

Prevent product contact with air

The dual-pig pigging system is specially designed for the processes that the liquid products are oxygen-sensitive. As exposure to the air may lead to much dissolved oxygen content and potential spoilage.

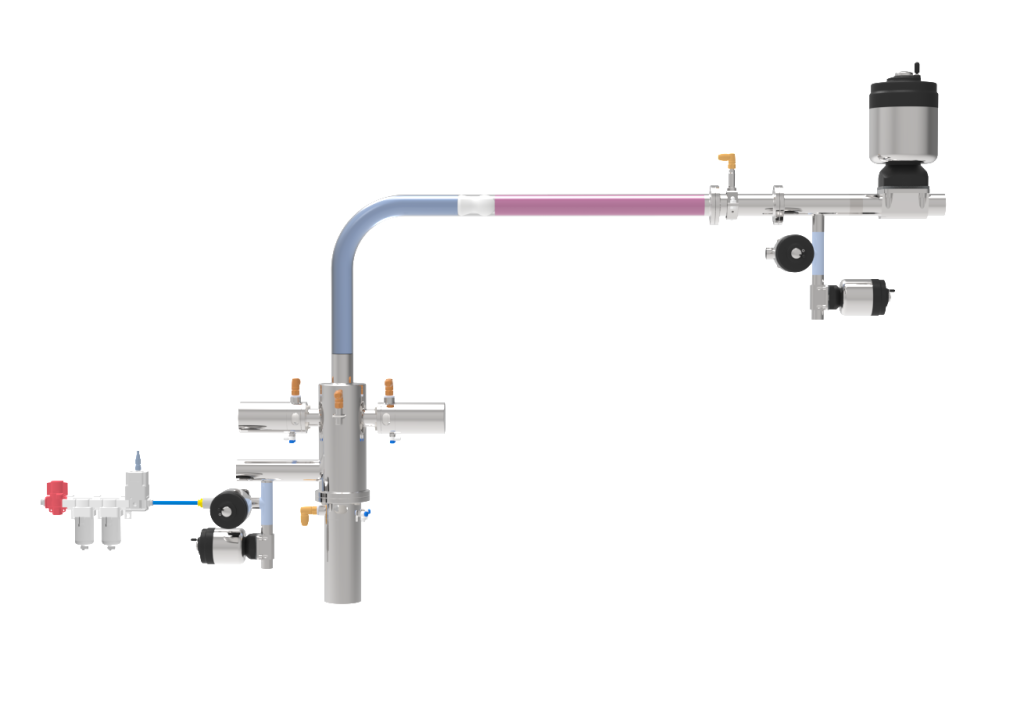

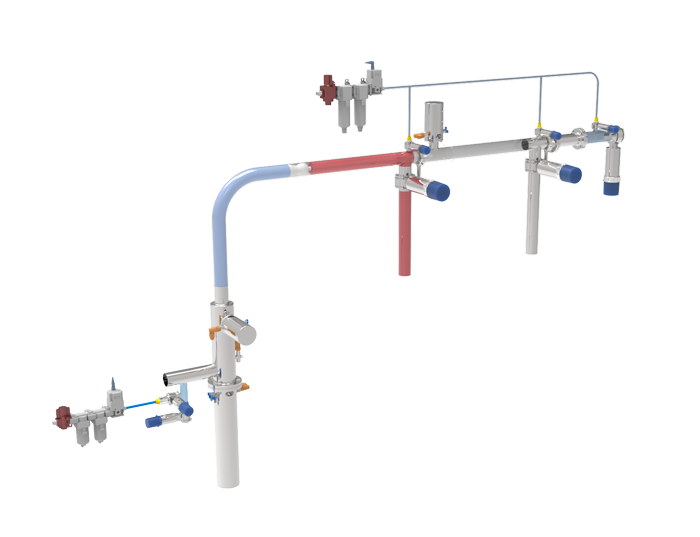

During the initial operation, the first pig is driven by product to the automatic stopper to evacuate the air and water in the pipeline. The pig works as a seal to block the outlet of the stopper, and prevent the product behind it from oxidizing due to air contact. Once product transfer is concluded, the clean compressed air starts to propel the second pig to push the residue product inside the pipeline into the storage tank below the stopper, and this marks the conclusion of the first pigging cycle. The procedure is similar for pigging operations directed to the receiving station.

Summary: How does it work?

- Phase 1: First pig removes air or water to prevent contact.

- Phase 2: Product transfer in an oxygen-free pipeline.

- Phase 3: Second pig recovers over 99% of the residue product.

Dual-Pig System: Technical Details & Components

Applications:

The dual pig system is suited to a diverse range of industries, including: paints, coatings, wine, foam gel, cosmetics.Features:

Benefits:

Specifications

| Item | Parameter |

|---|---|

| DIN11850 Piping | DN25, DN40, DN50, DN65, DN80, DN100, DN125, DN150 |

| ISO Piping | 1″, 1.25″, 1.5″, 2”, 2.5”, 3”, 3.5”, 4”, 5”, 6” |

| Material | SS304/SS316L ( for product- contact surfaces) |

| Pressure | ≤ 0.8MPa |

| Polishing | Ra≤0.8 |

| Temperature | ≤100°C |

| Sealing | EPDM,FKM,VMQ, other materials upon request |

Features

Technical data

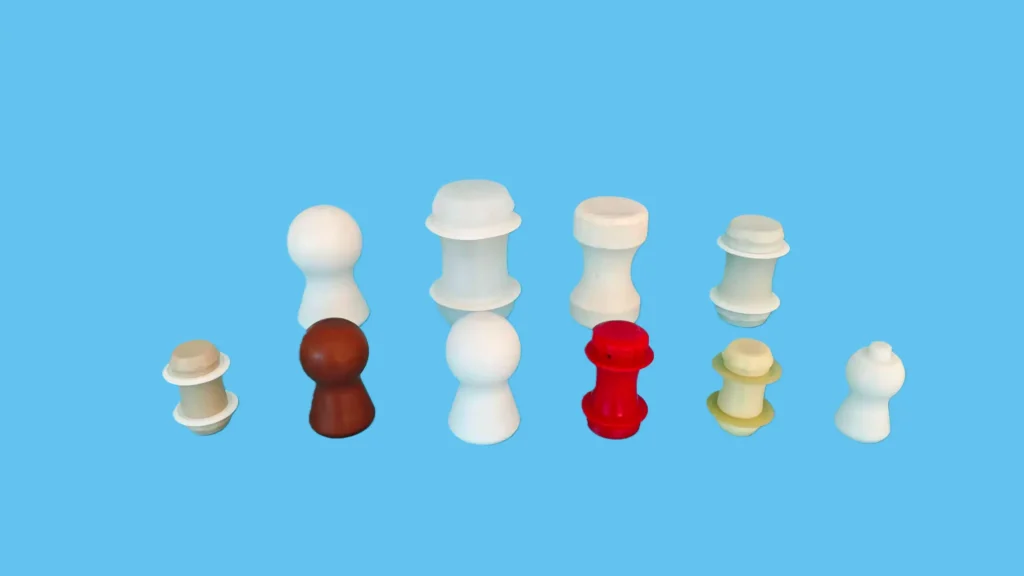

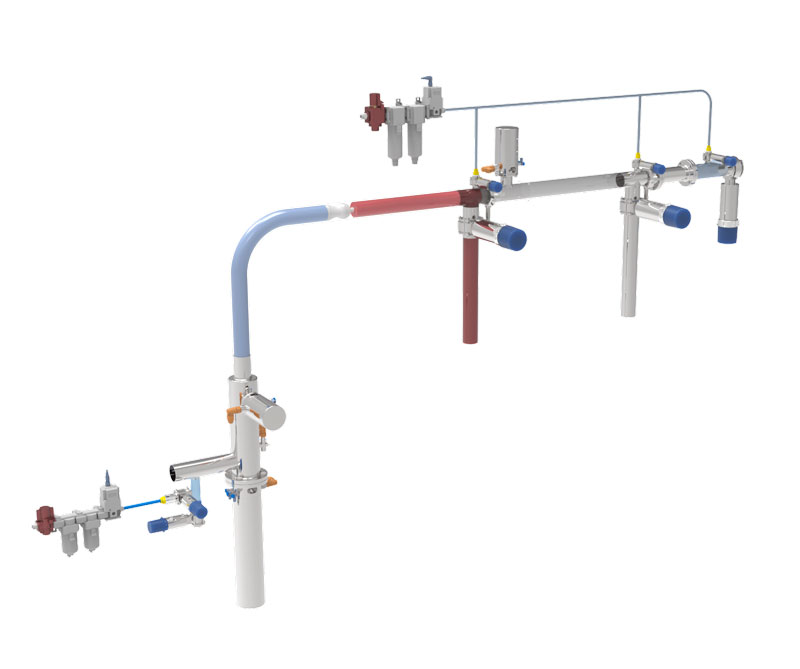

- Featured hygienic profile

- Placed side by side in dual-pig launcher

- The pig can be launched into the pipe by sequence

- Locatability: containing embedded magnetic cores for precise detection via Hyperfore pig detection unit.

- 3D/5D bends compatible

- Materials: available in VMQ, other materials upon request

- Piping size range: DN25-DN150, ISO1″-ISO6″

Introduction

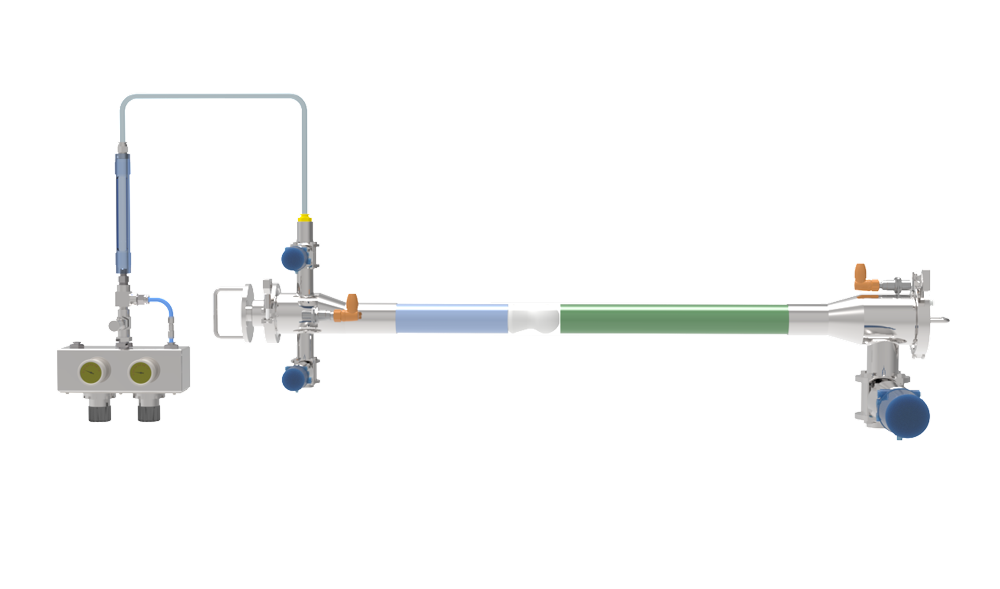

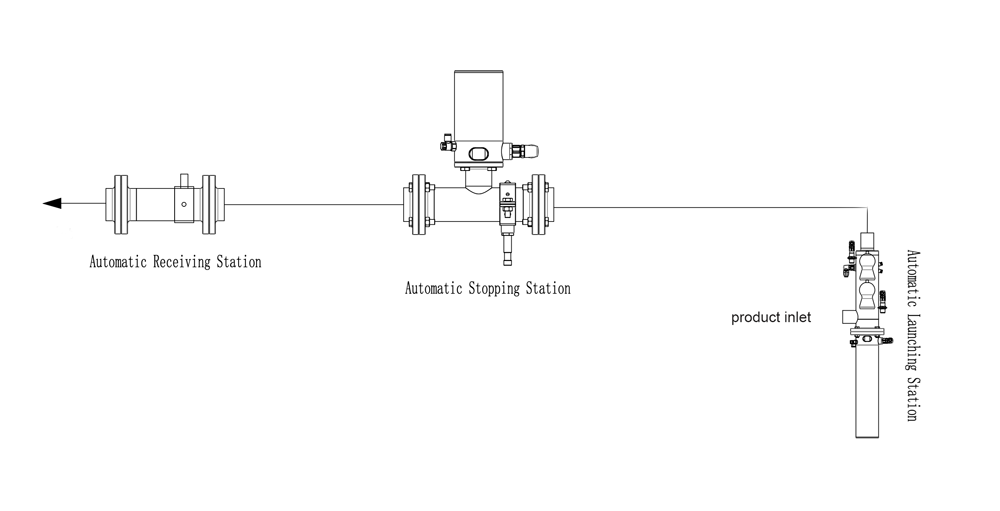

This automatic stopper is a critical component in pigging systems, the automatic stopper is primarily used to intercept the pig, leading it to stop at a specific location within the pipeline, and to recover product to a target tank near that location. It is designed to meet the needs for segmented product recovery and cleaning of certain pipeline sections.

Technical data

What Products Is This For?

Related Pigging Products

Related Pigging Cases

Contact Us

Have questions about dual-pig solutions? Use the form to reach out and we will contact you as quickly as possible.