What Is Pigging Process and How Pigging System Works?

Table of Contents

What Does Pigging Mean?

Pigging refers to the specialized process of using a “pig” – a cylindrical or spherical tool made of materials like VMQ , EPDM, FKM,PTFE and so on- to clean and recover valuable liquids from pipelines in a hygienic manner. Hyperfore sanitary pigging is particularly vital in industries such as food and beverage, cosmetics, pharmaceuticals, and personal care, where maintaining strict hygiene and preventing cross-contamination are essential.

The pig is inserted into the launcher and is launching into the pipeline, which contains residual liquid product. By utilizing the product flow or compressed air, the pig is propelled through the pipeline, effectively scraping and collecting the valuable liquid to the designated target tanks, which would otherwise be wasted.

Hyperfore sanitary pigging offers numerous benefits in liquid product recovery:

- Maximizing Yield: It allows companies to extract the maximum amount of product from pig pipes, reducing waste and enhancing profitability.

- Preventing Contamination: Sanitary pigging ensures that no foreign substances or residues remain in the pipeline, minimizing the risk of cross-contamination between different products.

- Maintaining Quality: The process preserves the quality and integrity of the recovered liquid product, as it remains uncontaminated and unaffected by contact with other substances.

- Improving Efficiency: Sanitary pigging reduces downtime during cleaning procedures, leading to increased productivity and improved operational efficiency.

- Sustainability: By recovering more liquid product and minimizing waste, sanitary pigging promotes sustainable practices and reduces environmental impact.

In summary, Hyperfore sanitary pigging is a crucial method for liquid product recovery, aligning with industry standards and providing a safe, efficient, and hygienic solution for maximizing yields and ensuring product quality in sensitive manufacturing environments.

How Many Types of Pigging Are There?

There are several types of pigging techniques used in different industries and applications, including:

- Cleaning Pigging: This type of pigging is focused on removing debris, contaminants, and buildup from the pipeline walls to maintain optimal flow efficiency and prevent blockages. Pipeline cleaning pigs help extend the lifespan of the pipeline and enhance overall operational performance.

- Product Recovery Pigging: Hyperfore sanitary pigs are designed to recover valuable liquid products that remain in the pig pipes after transfers or processing operations. This type of pigging reduces product waste, maximizes yield, and increases profitability for industries like food and beverage, pharmaceuticals, and cosmetics.

- Sanitary or Aseptic Pigging: Hyperfore sanitary pigging is crucial in industries that require strict hygiene standards, such as food processing and pharmaceuticals. It involves using specially designed pigs, launchers and receivers to prevent cross-contamination and ensure product integrity during liquid product recovery.

- Automated Pigging : Automated pigging systems use programmable logic controllers (PLCs) and sophisticated sensors to control the pigging process automatically . These systems offer precise control, data monitoring, and reduced human intervention, enhancing efficiency and safety.

- Manual Pigging: In manual pigging, operators physically control the pigging process, the pigs are manually launched into the launcher and retrieved from the pipeline. Although less automated, manual pigging is still effective for certain applications and allows for lower cost.

- Ice Pigging: Ice pigging is a non-destructive cleaning method that uses a slurry of ice and water to remove debris and buildup from the pipeline walls. It is commonly used in situations where traditional cleaning methods may be impractical or ineffective.

Each type of pigging has its unique advantages and applications, and the choice depends on factors such as the industry, specific requirements, and the desired outcomes for liquid product recovery, pipeline maintenance, and efficiency optimization.

FAQ For Pigging Systems

Pipeline Pigging Products

There are many pipeline pigging products used in various industries and applications, each serving a specific role in the pigging process:

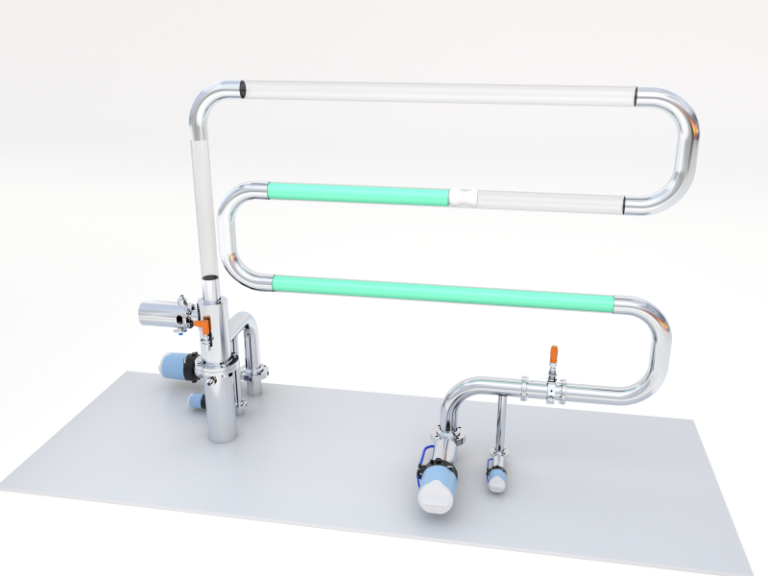

- Pig Launcher: A pig launcher is a mechanical device used to introduce pigs into the pipeline for cleaning, inspection, or product recovery. It provides a safe and controlled entry point for the pig.

- Pig Receiver: The pig receiver is another mechanical device located at the end of the pipeline, used to retrieve the pig after its journey through the pipeline is complete.

- Pipeline Pigs: Hyperfore pipeline pigs are sanitary, and they are bi-directional pigs, they can return to the launching station for CIP after the pigging task is complete.

- Pig Stopper: Hyperfore pig stopper, functions like the pig receiver, it can be installed before the destination tanks, but the pig can also pass through the stopper if necessary.

- Pig Speed Controller: A pig speed controller regulates the speed of the pig as it travels through the pipeline, ensuring safe and efficient movement.

- Pig Position Detector: This device monitors and provides real-time information about the pig’s position within the pipeline, allowing operators to track its progress and locate potential obstructions.

- Piggable 3-Way Diverter Valve: Hyperfore piggable 3-way diverter valve enables the redirection of pigs from one pipeline section to another, providing flexibility in pigging operations.

- Piggable 3D Elbows and Tees: These pipeline components have a pigging port that allows pigs to pass through smoothly, facilitating effective cleaning and liquid product recovery.

- Piggable Pipes: Piggable pipes are pipelines specifically designed to accommodate pigs for cleaning, inspection, and product recovery purposes. They have suitable dimensions and features to enable easy pig passage.

Each of these pipeline pigging products plays a crucial role in optimizing pipeline maintenance, liquid product recovery, and overall efficiency in various industries, pigging system can be used in oil and gas, food and beverage, pharmaceuticals, and more. The combination of these products enables companies to effectively utilize pigging technology to maximize yields, reduce waste, and ensure the integrity of their pipeline systems.

What Type of Pig Is the Right Choice?

The choice of Hyperfore pigs for liquid product recovery depends on various factors. Here’s a breakdown of the different pig types and their respective benefits:

- Tangent One-Piece Pig:

The Hyperfore tangent one-piece pigs adopts an integrated design and uses elastic materials that meet sanitary requirements and have minimal wear. Its unique shape provides a wear-resistant driving head and evenly distributed forces on the spherical force end, with a slender waist design. This allows it to pass smoothly through 3D bend or 5D bend, satisfying various complex engineering conditions. The tangent one-piece pig is also used for passing through eccentric tees. The internal permanent magnet adopts a protective encapsulation design, ensuring no particle contamination even in case of unexpected events.The tangent one-piece pig is sanitary.

Material of the tangent one-piece pig: VMQ (FKM, NBR, EPDM, PU,POK customizable).

2. Lip-Pig:

The Hyperfore lip pig consists of multiple sanitary-grade materials and flexible sanitary-grade lip seals. The unique design of the lip seals enhances the pig’s longevity and makes it more suitable for products with higher friction coefficients. The lip seals can be individually replaced, and the lip pig can freely pass through pipelines with 3D bend or 5D bend. The lip pipeline pig is sanitary.

Materials: Lip seals (VMQ, FKM, EPDM, etc.), sphere (POK, PFA, etc.).

3. Sanitary Pig: Sanitary pigs are specifically engineered to meet strict hygiene standards required in industries such as food processing and pharmaceuticals. They are made of food-grade materials and designed to prevent contamination during liquid product recovery, ensuring product integrity and safety.

4. Bi-Directional Pig: Bi-directional pigs can travel in both directions of the pipeline, offering added versatility. They are particularly useful when liquid product recovery needs to occur in either direction, providing operational flexibility and efficiency.

Related Articles

About Author: Hyperfore

Beijjing Hyperfore Technology Co.,Ltd. was founded in 2005, covers an area of 2400 square meters. We are engaged in the automation, project process design, production line electrical and mechanical installation, mechanical equipment research and manufacturing, pigging solutions. Our products and services cover sanitary pigging system, aseptic pigging system, manual pigging system, piggable 3-way diverter valves, pipeline pigs(scrapers), and other pigging products. Our customers spread across various industries around the world, including dairy, sauce, beverage, pharmaceutical, chemical and so on.