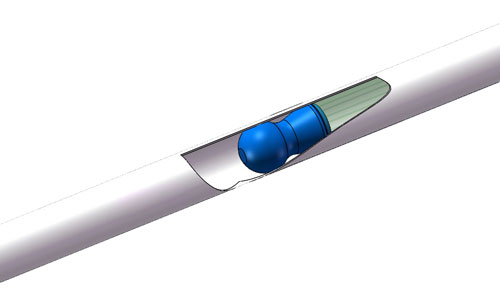

What Is the Pig Speed In Pipelines?

The Pig Speed In Actual Pigging Process

What is the pig speed in pipelines for actual pigging process? In food production pipeline and other sanitary pipelines. Pig is running under normal pressure (less than 2 bar and with back pressure). And during these situations, pig speed can be controlled between 0.5m per second to 1m per second.

Elements Affecting the Pig Speed In Pipelines

- The pipeline size, specifically, the pipe inner diameter may affects the pig speed

- Driving pressure that propel the bi-directional pig to run in the pipeline may affects the pig speed

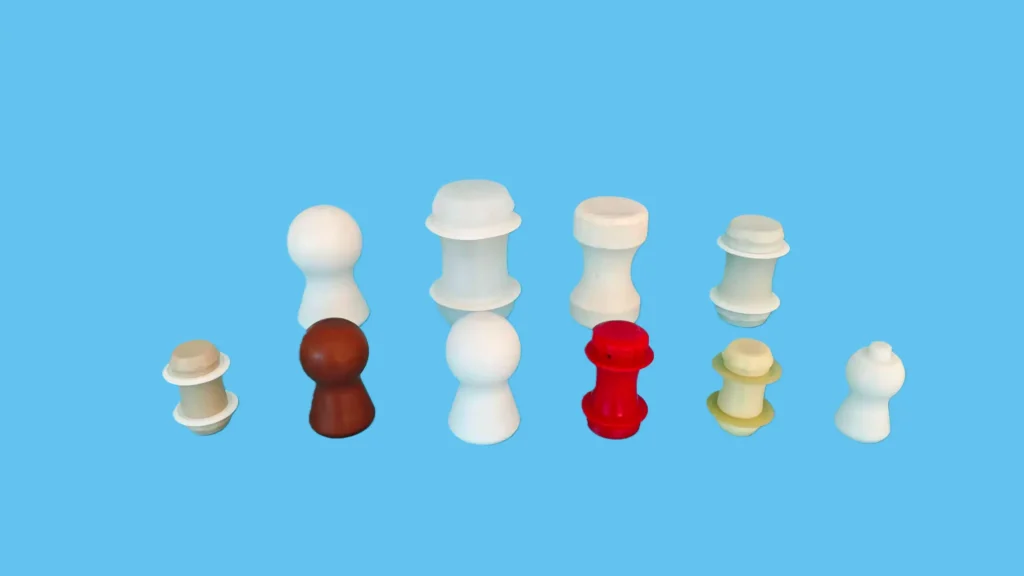

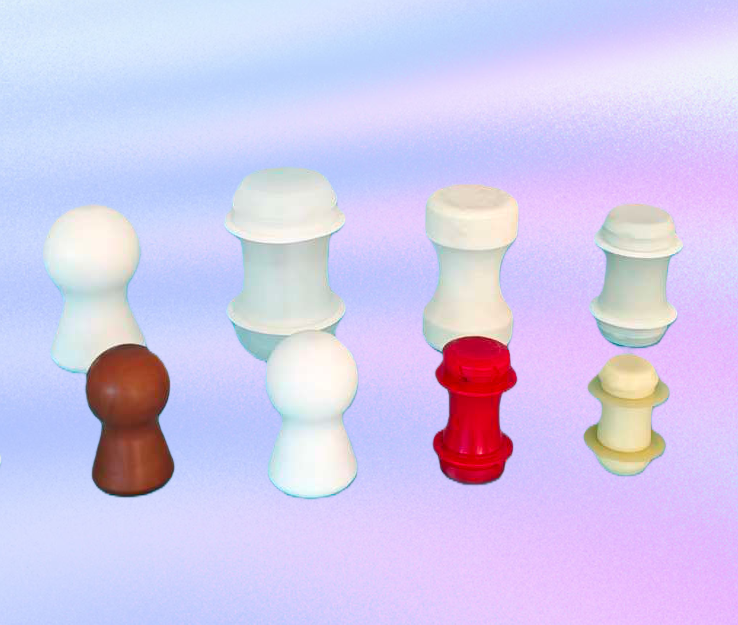

- The mass of the pig may affect the pipeline pig speed

- Pigging process design may affect the pipeline pig speed

- Liquid products being transferred may affect the pipeline speed

The Speed Of Air Driven Pipeline Pig In Testing

The speed of the pig is determined by the speed of pigging system design. Due to the lack of back pressure, the maximum speed of an open pigging system is higher than that of a closed system, the difference can reach up to 25%, according to different pipe size. Here we use a pigging system with an open end for testing.

The pigging system tested has the following features:

- The pipe size is ISO 4 inch

- End is open

- The mass of the pig is 0.7kg

- The maximum driving pressure is 4 bar

The pipeline pig stops due to the frictional force, and it begins to move on when the driving pressure increases high enough to overcome the frictional force. The pressure applied by the propellant to overcome static resistant force, the nominal size of the pipeline, the mass of the pipeline pig and the volume of the propellant can be used to calculate the maximum speed of the pipeline pig running along the pipeline.

The test result shows, after passing through a short distance, the pig has reached its maximum speed and then quickly stops. The following table lists the maximum speed of the pipeline pig under the above testing conditions, where different pipe diameters correspond to pipeline pig mass.

| Driving Force | Pipe Size 1 | Pipe Size 2 | Pipe Size 3 |

| 2inch (DN50) | 3inch (DN80) | 4inch (DN100) | |

| 2 bar | 10 m/s | 13 m/s | 15 m/s |

| 3 bar | 24 m/s | 35 m/s | 37 m/s |

| 4 bar | 53 m/s | 73 m/s | 76 m/s |

The pig speed is so high under the pressure of 6 bar, it is easily to be severely damaged when exiting the launching station and entering the receiving station, due to heavy wear and tear. As the speed increases, the amount of the residue increases, and the pigging effect worsens accordingly.

Know More About Pig Speed

Corrective Measure For Excessive Pig Speed

The practical solution to this problem is to limit the propelling pressure to 4 bar. In order to achieve a uniform pig speed, it is a good way to install a back pressure valve at the exhaust. Back pressure can control the acceleration of the pig, and ensure the pipeline pig to run at a uniform speed. The flow rate of the propellant should always be maintained at a sufficiently high level, therefore, the supply of air is never suppressed under any circumstances.

It is proved that the back pressure at a value that ensures the pig speed does not exceed 7m/s is reasonable and it can also reduce wear and tear. However, the pig speed has better not exceed 2m/s. Compared to liquid propellant device, air driven device (a pig speed controller)require a discharging system to release the air and subsequent propellant.

FAQ About Sanitary Pigs

Related Articles

Related Cases

Hello,

I’m Richard Gan, General Manager at Beijing Hyperfore Technology Company Ltd.

Since our founding in 2005, we have accumulated almost 10 years of focused experience in the Chinese market, specializing in the design and delivery of advanced sanitary pigging systems and integrated solutions.

If you have any questions, please feel free to contact us. We are pleased to provide you best products and services.

Email: wenbo.gan@hyperfore.cn WeChat: hyperfore2005

WhatsApp: +86 18910216756