Bi-Directional Pig VS Single Directional Pig In Pigging

Pipeline Pig Types and Introduction

The definition of pigging (liquid product recovery) is generally as the work performed by a movable plug or scraper inside a pipeline. Pipeline pig can also complete tasks such as liquid or powder product transportation, pipeline inspection, testing and repair. In applications such as agriculture, food, pharmaceutical, life science, and cosmetics, pigging has become an indispensable task.In addition, Pigging is beneficial for environmental protection, reduces energy consumption, and it can also decrease the amount of sewage discharge.

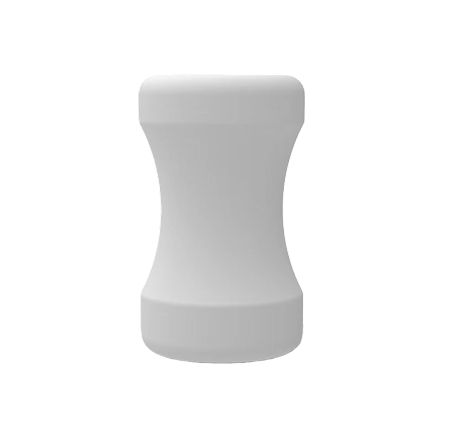

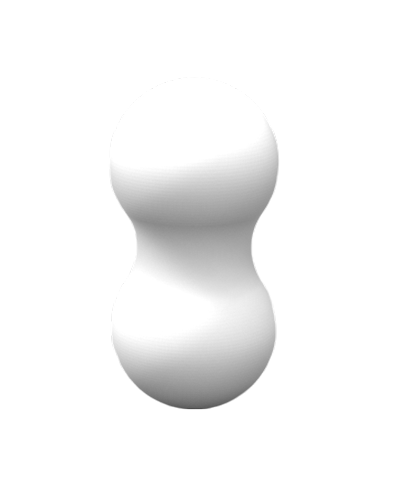

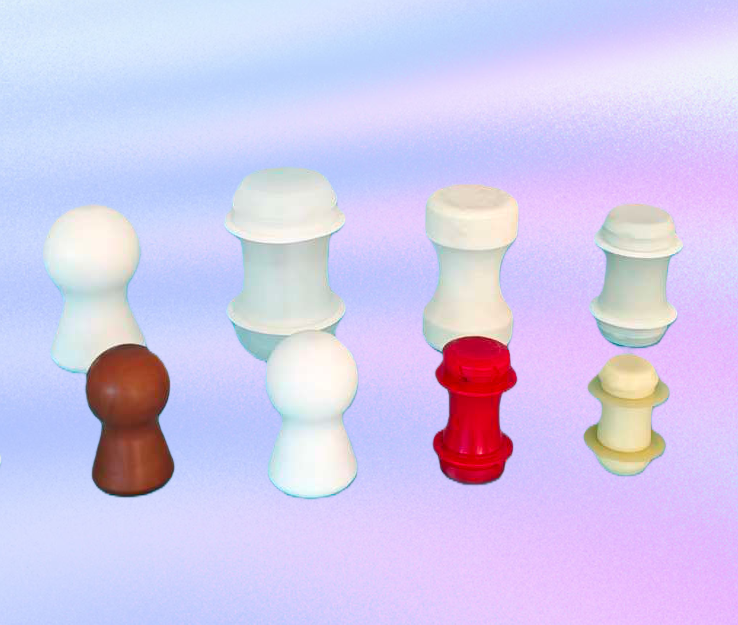

A pipeline pig is a movable part of pigging system (liquid product recovery system), it can be bi-directional or uni-directional, and the shape can be spherical, barrel spherical, cylindrical, with disc, lips and so on. Its size is a little larger than the inner diameter of the pipe, so a pig can tightly adhere to the inner wall of the pipe and seal the front and rear pipeline. There are various types of pipeline pig designs, specifications, dimensions, and material selection, so the application scope is also very broad.

Why To Choose Hyperfore Bi-Directional Pigs For Industrial Pigging?

The pig can run in the direction of product delivery (forward pigging) or in the opposite direction (reverse pigging).A pig that can run in both directions is called a bi-directional pig. All types of Hyperfore pigs are bi-directional pigs.

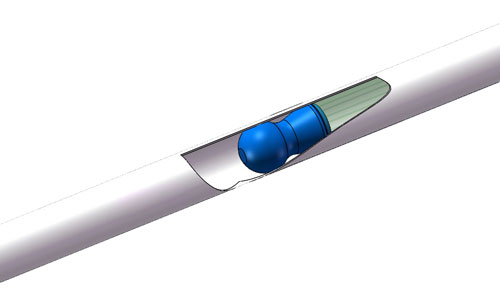

- One of the benefits is that, when pushed by the air propellant, the bidirectional pig can move directly from the launching station to the receiving station, or depart from the receiving station and return to the launching station. During a round of pigging process, the pig is always in a closed pipeline and does not need to come into contact with the outside, effectively ensuring the pigging operation hygiene and safety.

- The second advantage is that , there is a built-in permanent magnet box inside in the bidirectional pig, which can be sensed by the pig position detecting unit, so the pig movement is easy to be controlled by automation and PLC programs. The whole process is under control when the bidirectional pig arrives at the receiving station and returns to the launch stationing based on the pre-set steps of production and pigging process, saving human labor, saving products, and improving operational efficiency.

- The third advantage is that, the bi-directional pig can be cleaned or steamed in place (CIP’d or SIP’d). After pigging cycle is complete, the bidirectional pig returns to the launcher under the PLC control. Hyperfore pigging system (product recovery system) launcher is home base of the bidirectional pig, supplying enough space to hold the pig. The launcher also includes a chamber that can be used to lock the pig. When CIP liquid flushes the bi-directional pig, it will not be moved by the flowing liquid.

Drawbacks Of Single Directional Pig Compared To Bi-Directional Pig

- Firstly, when a single-directional pig, departs from the launcher and reaches the receiver, it has to be manually removed from the receiver for cleaning and sterilization. After that it is manually inserted into the launcher again, waiting for the next round of pigging operation. However, the single-directional pig may get polluted outside the pipeline, causing further contamination to the entire batch of products. And the process of manually removing and inserting may take a long time, lowering production efficiency, increasing downtime, and increasing overall costs due to relying on human labor. This is clearly a disadvantage compared to bi-directional pipeline pig.

- Secondly, single-directional pig cannot be fully controlled by automation, at least during the process of returning to the launching station. Therefore, the pig system is a semi-automated or fully manual controlled system, of course the efficiency of pigging is lower than that of a fully automated pig system.

- Thirdly, single directional (uni-directional) pig is manually removed from the receiver, cleaned and disinfected outside the pipeline. That is to say, single directional pig cannot be cleaned together with the system by CIP. Yet improper handling by the operator may result in unqualified disinfection, posing hygiene risk to the entire batch of product being processed. And significant economic losses may occur. This is another disadvantage compared to bi-directional pipeline pig.

- Fourthly, if the pigging pipeline is long, multiple times of manually removing and placing the uni-directional pipeline pig into the launching station may be a tedious task that consumes much time and increases overall cost, and pigging system return on investment is rather lower.

Conclusion From Comparing Two Types of Pipeline Pigs

After comparing, the performance and advantages of bi-directional pipeline pig are obviously superior to those of the uni-directional pig. Therefore, bi-directional pigs are widely used in various industries, such as petroleum, pigment, paints and coatings, chemical, animal husbandry products (such as skin cream), food (such as chocolate, beverages), and liquid pharmaceuticals. Bidirectional pigs can empty pipelines, recovering valuable products, separate different products, isolate products from propellants, and remove sediment from the pipe. The successful bi-directional pipeline pigging cases can achieve the minimization of resource consumption, reduce sewage discharge, and lower operating costs.

What Size Are Bi-Directional Pigs?

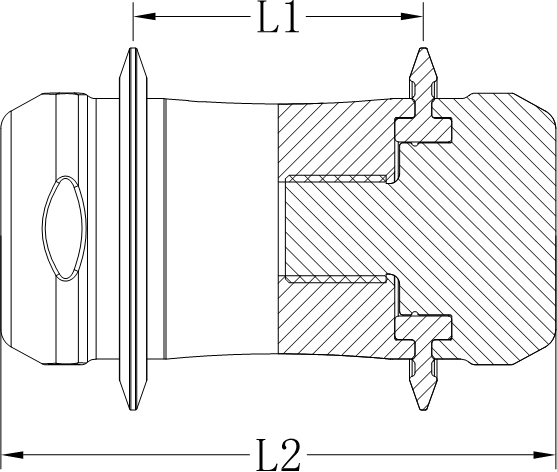

| PART NO. | SIZE | OD*T | L1 | L2 | WEIGHT/G |

|---|---|---|---|---|---|

| DCPMS01D025A | DN25 | Φ29*1.5 | |||

| DCPMS01D040A | DN40 | Φ41*1.5 | |||

| DCPMS01D050A | DN50 | Φ53*1.5 | |||

| DCPMS01D065A | DN65 | Φ70*2.0 | |||

| DCPMS01D080A | DN80 | Φ85*2.0 | |||

| DCPMS01D100A | DN100 | Φ104*2.0 | |||

| DCPMS01D125A | DN125 | Φ129*2.0 | |||

| DCPMS01D150A | DN150 | Φ154*2.0 |

| Part Nr. | SIZE | OD*T | L1 | L2 | WEIGHT/G |

|---|---|---|---|---|---|

| DCPMS01T025A | 1″ | Φ25.4*1.5 | |||

| DCPMS01T032A | 1.25″ | Φ31.8*1.5 | 25 | 50 | |

| DCPMS01T038A | 1.5″ | Φ38.1*1.5 | 34.2 | 61.4 | 47.4 |

| DCPMS01T051A | 2″ | Φ50.8*1.5 | 43.3 | 82.8 | 113.4 |

| DCPMS01T064A | 2.5″ | Φ63.5*2.0 | 50.3 | 99.8 | 195.4 |

| DCPMS01T076A | 3″ | Φ76.1*2.0 | 65.5 | 117.5 | 348.6 |

| DCPMS01T089A | 3.5″ | Φ88.9*2.0 | 75.5 | 137.5 | 607.8 |

| DCPMS01T101A | 4″ | Φ101.6*2.0 | 84.8 | 156.3 | 854.2 |

| DCPMS01T127A | 5″ | Φ127*2.0 | |||

| DCPMS01T152A | 6″ | Φ152.4*2.0 | |||

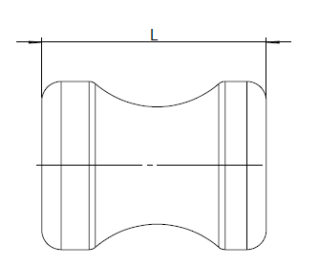

| PART NO. | SIZE | OD*T | L(MM) | WEIGHT/G |

|---|---|---|---|---|

| DCPLXDXD025A | DN25 | Φ29*1.5 | ||

| DCPLXDXD040A | DN40 | Φ41*1.5 | ||

| DCPLXDXD050A | DN50 | Φ53*1.5 | ||

| DCPLXDXD065A | DN65 | Φ70*2.0 | ||

| DCPLXDXD080A | DN80 | Φ85*2.0 | ||

| DCPLXDXD100A | DN100 | Φ104*2.0 | ||

| DCPLXDXD125A | DN125 | Φ129*2.0 | ||

| DCPLXDXD150A | DN150 | Φ154*2.0 |

| Part Nr. | SIZE | OD*T | L(MM) | WEIGHT/G |

|---|---|---|---|---|

| DCPLXDXT025A | 1″ | Φ25.4*1.5 | ||

| DCPLXDXT032A | 1.25″ | Φ31.8*1.5 | 25 | |

| DCPLXDXT038A | 1.5″ | Φ38.1*1.5 | 34.2 | |

| DCPLXDXT051A | 2″ | Φ50.8*1.5 | 43.3 | |

| DCPLXDXT064A | 2.5″ | Φ63.5*2.0 | 50.3 | |

| DCPLXDXT076A | 3″ | Φ76.1*2.0 | 65.5 | |

| DCPLXDXT089A | 3.5″ | Φ88.9*2.0 | 75.5 | |

| DCPLXDXT102A | 4″ | Φ101.6*2.0 | 84.8 | |

| DCPLXDXT127A | 5″ | Φ127*2.0 | ||

| DCPLXDXT152A | 6″ | Φ152.4*2.0 | ||

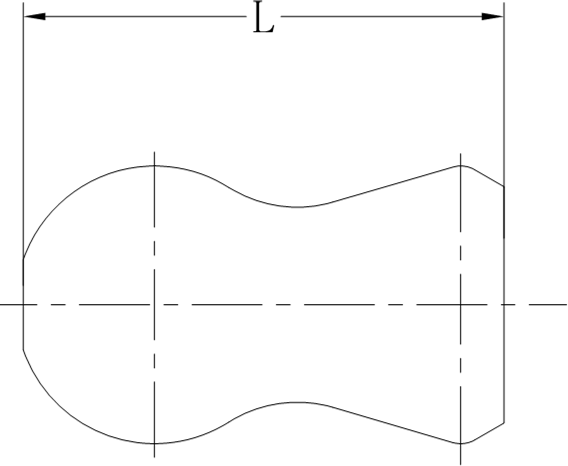

| PART NO. | SIZE | OD*T | WEIGHT(G) |

|---|---|---|---|

| DCPMB00D025A | DN25 | Φ29*1.5 | 28 |

| DCPMB00D040A | DN40 | Φ41*1.5 | 84.4 |

| DCPMB00D050A | DN50 | Φ53*1.5 | 184.8 |

| DCPMB00D065A | DN65 | Φ70*2.0 | 394.7 |

| DCPMB00D080A | DN80 | Φ85*2.0 | 695 |

| DCPMB00D100A | DN100 | Φ104*2.0 | 1322.8 |

| DCPMB00D125A | DN125 | Φ129*2.0 | |

| DCPMB00D150A | DN150 | Φ154*2.0 | |

| PART NO. | SIZE | OD*T | WEIGHT(G) |

|---|---|---|---|

| DCPMB00T025A | 1″ | Φ25.4*1.5 | 18.66 |

| DCPMB00T032A | 1.25″ | Φ31.8*1.5 | 37.5 |

| DCPMB00T038A | 1.5″ | Φ38.1*1.5 | 66.6 |

| DCPMB00T051A | 2″ | Φ50.8*1.5 | 160 |

| DCPMB00T064A | 2.5″ | Φ63.5*2.0 | 300 |

| DCPMB00T076A | 3″ | Φ76.1*2.0 | 480 |

| DCPMB00T089A | 3.5″ | Φ88.9*2.0 | 821.4 |

| DCPMB00T101A | 4″ | Φ101.6*2.0 | 1237.8 |

| DCPMB00T127A | 5″ | Φ127*2.0 | |

| DCPMB00T152A | 6″ | Φ152.4*2.0 |

Hyperfore Bi-Directional Pigging Solutions

All Hyperfore pigs are bi-directional with detectable magnetism. Our pigs are made of various food proof materials, and high-temperature and corrosion-resistant materials. It is exquisitely designed, strong and durable, with long life-span. Compared with pipeline pigs of other brands in the market, it is more cost-effective.

Hyperfore are engaged in customized bi-directional pigging solutions and pigging products, please feel free to contact us for any questions. Our professional team will do our best to provide you with the most suitable solutions and suggestions for any application.

FAQ

Hello,

I’m Richard Gan, General Manager at Beijing Hyperfore Technology Company Ltd.

Since our founding in 2005, we have accumulated almost 10 years of focused experience in the Chinese market, specializing in the design and delivery of advanced sanitary pigging systems and integrated solutions.

If you have any questions, please feel free to contact us. We are pleased to provide you best products and services.

Email: wenbo.gan@hyperfore.cn WeChat: hyperfore2005

WhatsApp: +86 18910216756

Let us know how we can help you!

To improve the profits, reduce waste and improve competitiveness of your business through bi-directional pigging application, contact Hyperfore today!