Pipeline Cleaning and Pipeline Cleaning Pigs

The Need for Pipeline Cleaning

Pipelines are widely used in different industries. For liquid product transferring industries, such as dairy, beverage, sauce, cosmetics, chemicals and so on, liquid products are transmitted by stainless steel pipelines to ensure product hygiene and prevent contamination.

In order to maintain the quality of the liquid products transferred in the pipelines, regular pipeline cleaning becomes crucial. Clean pipelines also have positive impact on the performance of production efficiency.

Problems of Your Pipelines to Be Cleaned

To choose a suitable cleaning method, it is important to identify the problems of your pipelines.

- During production, some particles in the fluid may stick to inner wall of the pipeline. The pipeline wall may become thick, and the inner diameter becomes smaller, and the flow becomes lower than normal.

- The sediment and impurities on the inner wall of the pipelines mix into the liquid product, and affect the quality of the fluid.

Several Pipeline Cleaning Methods

Flushing: It is a method of using water to clean the pipes. It is a very easy method, yet it might cost a lot of water and time. And this method is mainly useful for knocking off loose debris that might be in a pipe.

CIP: It means clean in place system. A method of using water, acid, alkali, cleaning fluid to clean repeatedly. The process can be 3 steps: acid cleaning, alkali cleaning, and final cleaning. Or 5 steps process: water cleaning, alkali cleaning, water cleaning, acid cleaning and final cleaning. Generally speaking, the longer the cleaning time, the better the cleaning effect.

But when there is a large amount of debris in the pipeline, the cost of CIP can be very expensive and time consuming.

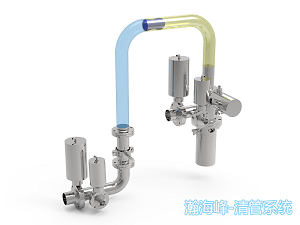

Pigging: Pigging is a method of using pigging system to clean the pipelines. A pig or the scraper runs along the pipes to scrap off the debris stuck to the wall of the pipes, and push the remained liquid products inside the pipes to tanks for recovery. It is widely used in many liquid processing industries. Hyperfore provide professional pigging solutions and sanitary pipeline cleaning pigs.

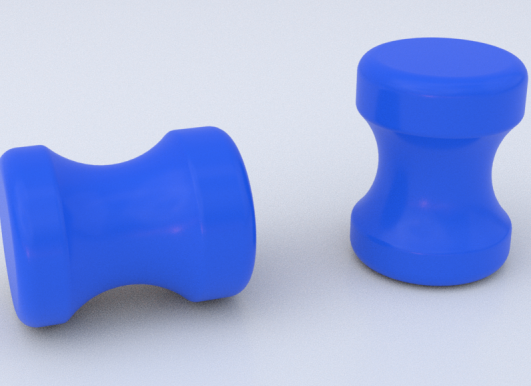

Pipeline Cleaning Pigs

Speaking of pipeline pigging, one can’t neglect pipeline cleaning pigs. There are several different types of pipeline cleaning pigs depending on the fields that they are applied to.

Spherical pipeline cleaning pig, Integral pouring pipe cleaner pig, bowl pipe cleaner pig, multiple components pig, aseptic pipeline cleaning pig, sanitary pipeline cleaning pig.

Hyperfore Pigs for Pipeline Cleaning

Hyperfore specialized in sanitary pigging solutions, we supply sanitary pigs, aseptic pigs. The detailed classification of our pipeline cleaner pigs are one-piece pipeline cleaning pigs, lip pipeline cleaning pigs and so on.

How Pipeline Cleaning Pigs Work

Hyperfore pipeline cleaner pigs are made of soft and elastic materials such as VMQ, EPDM and so on. The diameter of the pipeline cleaning pig is slightly larger than the inner diameter of the pipeline. They can fit tightly into the inner wall of pipeline. Liquid products can’t leak sideways. Pipeline cleaning pig runs along the pipes that transferring liquid materials. It is pushed by air, water or liquid products themselves. For liquid food or other sanitary liquid product processing pipelines, the propelling pressure for pushing the pipeline cleaning pigs are between 2 to 4 bars. As the pig runs along the pipes, it pushes the product to the destination tanks for recovery and cleans the pipelines at the same time.

The Pipeline Cleaning Process

Pigging begins after the pipeline cleaner pig is introduced to the pipeline and it is pushed through the pipeline. The pipeline cleaner pig can be introduced to the pipe manually or automatically. It is launched by the pipeline pig launcher, and stopped by the pig received. When pipeline cleaning pig arrives at the receiving station, the liquid products are collected for sale or further processing. Pipe pig cleaning is done inside the pig launcher by CIP.

Pipe Pig Cleaning

Pipe pig cleaning can be done inside the pipeline or outside the pipeline for Hyperfore pigging systems. For manual pigging system. Pipeline cleaning pigs are manually taken outside the pipes for cleaning, and re-inserted into the pipeline for next pigging process. Yet for automatic pigging system, Pipe pig cleaning is done inside the launcher. The Pipeline cleaning pig is cleaned by CIP together with other equipment of the production line.

Benefits of Using Pipeline Cleaning Pigs

Comparing with traditional pipeline cleaning methods, benefits of using pipeline cleaning pigs are multiple. First, it improves cleaning efficiency, it takes less time and the pipelines are cleaner. Second, it is cost-effective. Pigging with pipeline cleaning pigs consumes less water and cleaning detergents, as a result. money is saved and waste water treatment cost is lowered. Pigging is environmentally friendly.

Applications of Pipeline Cleaning with Pigs

Industries Relying on Pipelines

Operation of many liquid processing industries rely on pipelines. Beverage, water, dairy, cosmetics, chemicals, oil and gas plants use pipelines to process and manufacture products. Effective cleaning of pipelines is essential for these industries. The cleanness and hygiene of the pipelines directly affect the product quality, and the method of pipeline cleaning have a crucial impact on the cost and profits of the plants.

Specific Applications

For some specific applications, like removing paints and coatings from the inner wall of pipelines, the requirement for residue amounts is very strict. Because a little colorful residue paints or coatings may contaminate the whole batch of products. In such case, enough testing must be done to prove the effectiveness. While cleaning some pipelines that transfer a certain corrosive or explosive chemicals, pipeline cleaning pigs and sealings, pigging products have to be customized.

Conclusion

For many liquid product manufacturers, pipelines are very important facilities in the plants, The heathy station of pipelines have a very crucial impact on the product quality, company profits and sustainability, and environment protection. Pigging is cost-effective method for pipeline cleaning. Pipeline cleaning pigs play important role on pigging performance. Pipeline Pigging brings many benefits, like saving cost, improve yielding and profits, and it is friendly to the environment. Pigging as a popular pipeline cleaning method has been applied to many fields, especially liquid and powder processing fields. In some special cases, when the pipeline cleaning requirement is very high, special pigging process and pigging system equipment have to be customized and tested to match the demanding needs.

Pipeline cleaning is a significant step for maintaining pipeline integrity and efficiency. Pigging system including pipeline cleaning pigs is good tool for pipeline cleaning. How to implement the pigging process and how to choose the suitable pigging system, pipeline cleaning pigs is what professional pigging companies do. Hyperfore is one the companies who are dedicated to pipeline cleaning solutions.

Related Articles

Hello,

I’m Richard Gan, General Manager at Beijing Hyperfore Technology Company Ltd.

Since our founding in 2005, we have accumulated almost 10 years of focused experience in the Chinese market, specializing in the design and delivery of advanced sanitary pigging systems and integrated solutions.

If you have any questions, please feel free to contact us. We are pleased to provide you best products and services.

Email: wenbo.gan@hyperfore.cn WeChat: hyperfore2005

WhatsApp: +86 18910216756

Let us know how we can help you!

To choose suitable sanitary pigging solutions to clean pipelines and collect liquid products. Guarantee hygiene and maintain quality of production with pipeline cleaning pigs, contact Hyperfore today!