What Is Pipeline Pigging (System)?

Table of Contents

Pipeline Pigging

Pipeline pigging refers to the process of using a device called a “pig”or “scraper” to clean, inspect, or maintain pipelines in various industries. The term “pig” is derived from the squealing sound it makes while moving through the pipeline.

A pipeline pig (Hyperfore pigs are bi-directional, not single directional) is a specialized tool that is inserted into the pipeline and propelled by the flow of the product or hygienic compressed air. It travels through the pipeline, performing different functions depending on its type and purpose.

The primary objective of Hyperfore pipeline pigging is to recover residual liquid products and maximize yield. Recovery pigs are utilized in various industries, including beverage, alcohol, dairy, pharmaceuticals, cosmetics, etc., to recover different types of liquid products transported through pipelines. Cleaning pigs are used to remove debris, sediment, and other build-up that accumulates on the inner walls of the pipeline. This helps maintain the pipeline’s flow capacity and prevents blockages.

The process of Hyperfore pipeline pigging involves preparing the pipeline, launching the pig, monitoring its movement, and retrieving it at the designated location. Pigging can be performed on various types of pipelines, including those used for transporting food, oil, water, chemicals, lithium battery slurry and other fluids.

Hyperfore pipeline pigging offers multiple benefits, including significant product residue reduction, higher productivity, improved efficiency, cost savings, enhanced safety, and environmental protection. It plays a critical role in both liquid product manufacturing and routine pipeline maintenance.

What Is Pigging and How Pigging System Works?

Typical Pipeline Pigging Applications

Hyperfore Pigging System Can Be Applied To The Following Fields To Recover Liquid Products And Help Enhance Productivity and Decreasing Waste.

How Does Pipeline Pigging Work?

In the sanitary field, Hyperfore pipeline pigging is commonly used for cleaning pipelines and recovering products in industries such as food and beverage, pharmaceuticals, cosmetics, and personal care products. The goal is to ensure hygiene standards, product quality, and efficient production processes.

Hyperfore pipeline pigging in the sanitary fields follows a similar process as in other industries, with some specific considerations:

- Preparation: The pipeline section to be pigged is isolated, and pig launchers and receivers are used. Special attention is given to maintaining sanitary conditions throughout the pigging process to prevent contamination.

- Pig insertion: The sanitary pig, or scraper ,typically made of food-grade or pharmaceutical-grade materials, is inserted into the pipeline through the launcher. It is propelled by the product flow or compressed air.

- Cleaning: Sanitary pigs are designed to remove product residue, contaminants, and buildup from the pipeline walls. They have soft or flexible materials, or scraping elements to ensure thorough cleaning without damaging the pipeline surface.

- Rinse and flush: After the cleaning process, the pipeline is thoroughly rinsed and flushed with clean water or appropriate sanitizing agents to remove any remaining traces of the pig and ensure sanitation.

- Another pigging cycle: The pig is waiting in the launcher for subsequent pigging cycles.

Regular pigging in the sanitary field helps maintain hygienic conditions, prevent cross-contamination, and ensure compliance with regulatory standards. It improves product quality, reduces the risk of product recalls, and enhances the overall efficiency of the manufacturing process. Additionally, Hyperfore pigging can minimize product loss, optimize yield, and reduce the amount of waste generated during production.

Pigging Components:

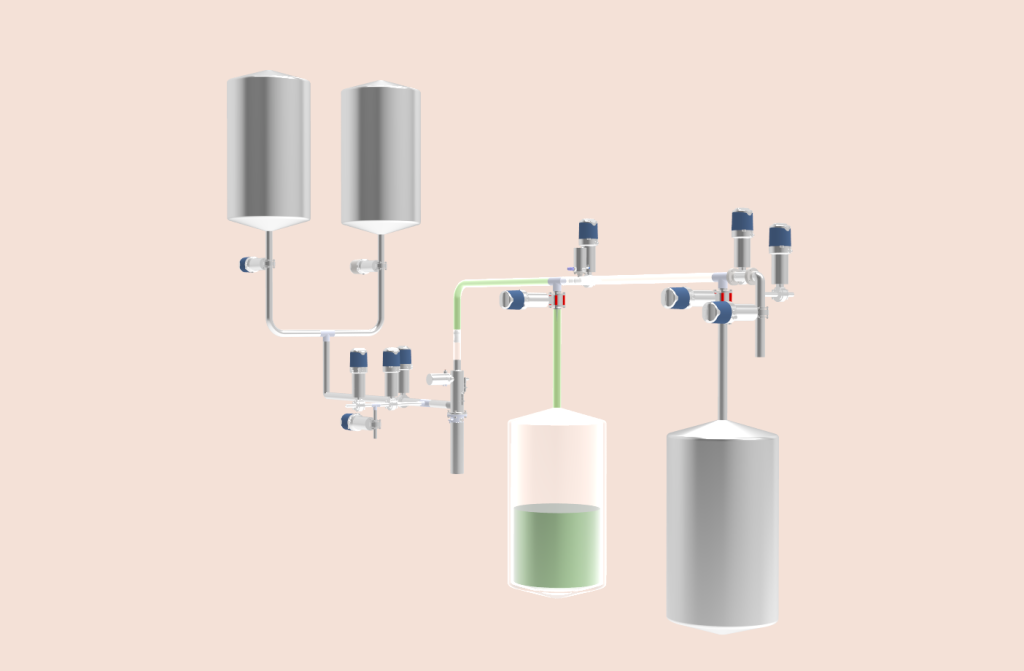

A pigging system typically consists of several key components that work together to facilitate the pigging process. These components include:

- Pig Launcher: The pig launcher is a vessel or chamber at the starting point of the pipeline. It provides a controlled entry point for the pig into the pipeline.

- Pig Receiver: The pig receiver is a vessel or chamber located at the endpoint or designated point of the pipeline. It is designed to safely capture the pig as it completes its journey through the pipeline.

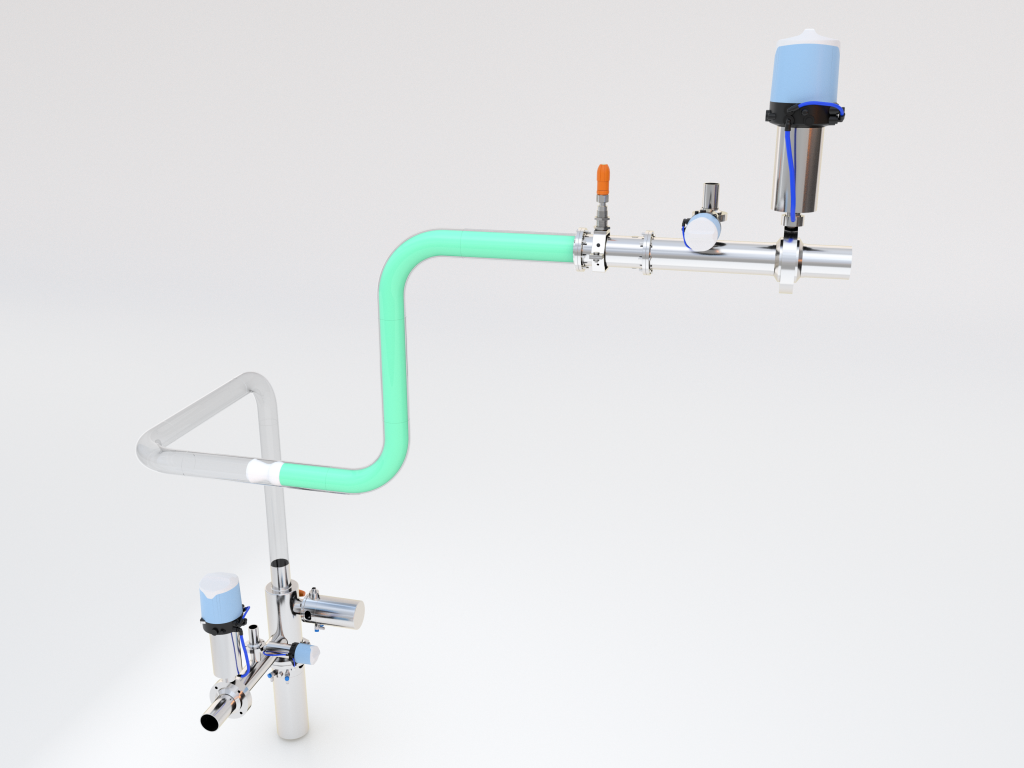

- Pig: The pig also called the scraper is the primary component of a pigging system. It is a specialized device inserted into the pipeline to perform cleaning, recovering tasks. Pigs can vary in design and construction depending on their purpose, such as the one-piece pig and the lip pig.

- Pig Detecting System: To detect the pig’s progress through the pipeline, a pigging system may include detecting equipment. This can involve using magnetic or acoustic sensors placed at strategic points along the pipeline to detect the pig’s location and monitor its movement in real-time.

- Pigging Control System: A pigging control system provides the means to control and monitor the pigging process. It typically includes valves, pressure gauges, and control panels to regulate the flow, pressure, and speed of the pig within the pipeline.

- Pigging Fluid: Pigging requires the use of a suitable pigging fluid, which is introduced into the pipeline to propel and lubricate the pig during its journey. The choice of pigging fluid depends on factors such as the nature of the product being transported and the specific requirements of the pigging operation.

- Isolation Valves and Bypass Lines: Isolation valves and bypass lines are essential components that allow for the isolation and redirection of the product flow during the pigging process. These enable safe and controlled access to the pipeline for launching and retrieving the pig.

These components work together to facilitate efficient and effective pigging operations, ensuring the integrity, cleanliness, and optimal performance of the pipeline system.

Related Articles

Hello,

I’m Richard Gan, General Manager at Beijing Hyperfore Technology Company Ltd.

Since our founding in 2005, we have accumulated almost 10 years of focused experience in the Chinese market, specializing in the design and delivery of advanced sanitary pigging systems and integrated solutions.

If you have any questions, please feel free to contact us. We are pleased to provide you best products and services.

Email: wenbo.gan@hyperfore.cn WeChat: hyperfore2005

WhatsApp: +86 18910216756