9 Benefits Of Sanitary Pigging Systems For Food Industry

What Is Pigging System and How Pigging Works?

What is pigging? Pigging system is a kind of liquid product recovery system and equipment. It can be applied to many liquid processing fields, including food processing industry. Any food that can be pumped to the pipeline can also be pigged. After product transferring, the pig is launched from the launcher to the pipe, it is pushed by sanitary air or water to travel along, meanwhile it scraps off almost all the product remained in the pipes and make them able to be sold. This is how pigging system works.

Sanitary pigging systems(also called product recovery systems)are especially beneficial to the food industries in many aspects. In the following paragraphs we will tell you these advantages food companies can get through hygienic pigging applications, from an expertise point of view.

9 Benefits Of Pigging System For Food Industry

1.Minimize Product Waste

Sanitary pigging systems are liquid product recycling equipment from the perspective of their function. The pigging procedure can optimize production process. They are used to recover residue liquid product in the pipelines. After pumping, there is always some product remained in the pipeline, if they are not able to be recovered, they will definitely be wasted. Hyperfore pigging systems can reduce liquid products waste and make them available for sale again. And the overall yielding and profits is also boosted for customers.

2. Optimizing Pipeline Cleaning

Sanitary pigging system can make pipeline cleaning easier. After the process of product transferring. There is a considerable amount of liquid product leftover in the pig pipes. Normal treatment is to flush them away with a lot of hot water and cleaning agent. The pipeline cleaning procedure lasts very long, and energy consumption is huge, for instance in paints and coatings pipelines. Production downtime is long and efficiency becomes low. But pigging system can change the situation. Recycled products can be resold. The leftover inside pipeline is little. Water and energy consumption is largely reduced. Pipeline cleaning becomes faster and easier.

3. Increasing Uptime and Profits

Time unrelated to production is reduced, as a result uptime is largely increased. Output and Profits are increased accordingly.

4. Cut Down Cross-Contamination

If the pipeline produces more than one product, like paints and coatings. The color or taste of one product should not contaminate another one. On account of the excellent cleaning effect of pigging system, this purpose is perfectly achieved. Cross contamination between different products are largely reduced, production quality is raised.

5. Applicable To Any Liquid Food That Can Be Pumped

Hyperfore sanitary pigging systems can be applied to a wide range of food products. For instance, sauce, candy, curry, mayonnaise, meat paste, syrup, chocolate, seasonings, toothpaste, pet food, pharmaceuticals and so on. Any food that can be pumped can be pigged as well.

6. Reduce Water Waste Use

Because there is little amount of product left inside pipeline after pigging, the CIP process needs much less water and cleaning agents. As a result, the waste water discharge is cut down, the waste water treatment cost is largely decreased.

7. Increasing Environment Sustainability

An environmentally friendly enterprise emits small amounts of waste, which also ensures its long-term development. Pigging systems make liquid product manufacturers environmentally friendly and beneficial.

8. Fast Return On Investment

Investment in Hyperfore pigging systems can be quickly recovered, the period can be 6 months to one year. Our sanitary pigging systems have good cost performance ratio. It can help manufacturers save considerable costs from a long- term perspective.

9. Easy Operation And Good Training Service

Hyperfore pigging systems can be easily operated. Our team supply training on operation and usage, and we offer on-site and remote technical support services.

Pigs For Food Companies

Sanitary pigs developed for food industries used materials that can meet the food grade standard. Hyperfore pigs is manufactured in accordance with FDA regulations

Hyperfore supplies 4 types of sanitary pigs for food industry

One-piece pig: VMQ, EPDM, FKM, etc. The pigs are suitable for various liquid food products

One-piece double shoulder pig: VMQ, EPDM, FKM, etc. The pigs are suitable for food that are very sticky

Lip pig: VMQ, EPDM, PP, POK, etc. The pigs are suitable for liquid products with particles and frictions

Turbo Jet pig: VMQ, EPDM, PP, POK, etc. The pigs can be applied to recover food powder in pipelines

Food Manufacturers That We Work With

Hygienic and Aseptic Pigging Systems

Specifically designed for food, beverages, chocolate ,syrup and pharmaceuticals etc.

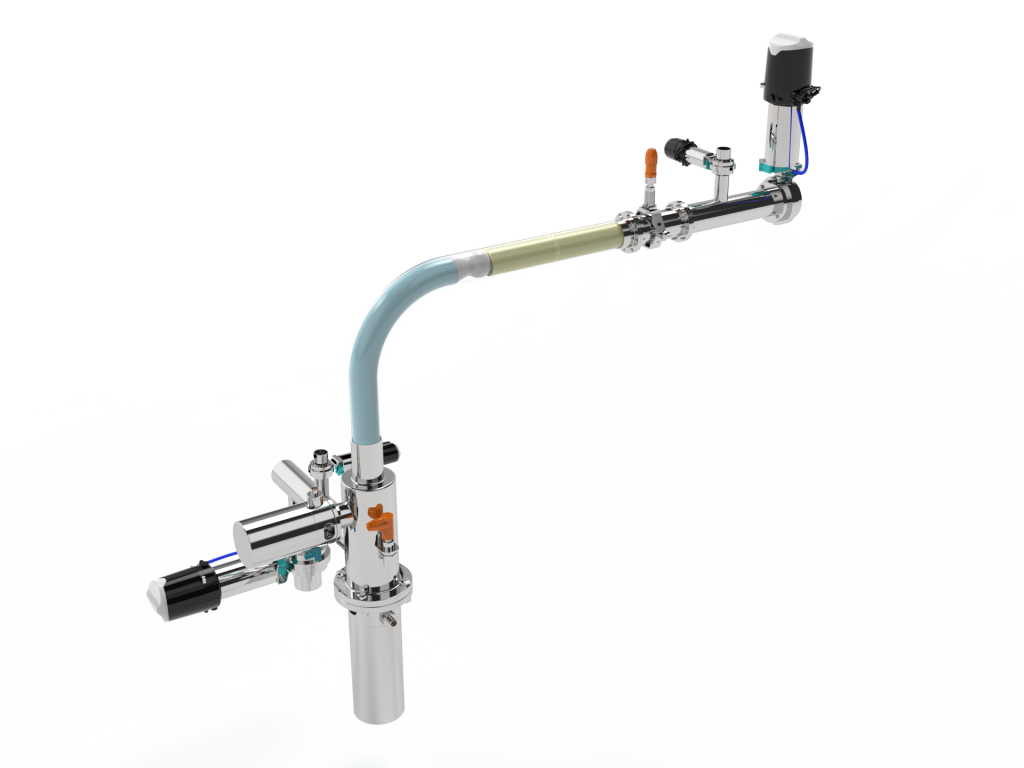

Hyperfore pigging systems (product recovery systems) are sanitary (hygienic). The internal area of both launching station and receiving station is without dead corners. The material is 316L stainless steel, and its inner surface and outer surface have undergone electropolishing to match with the food grade standard. Our pigging products like launchers, receivers, pig stoppers, and piggable valves can all be used for food and relative industries.

Automated sanitary product recovery system

Hyperfore automated pigging systems are sanitary, suitable for product recovery in food, beverage and similar industries. The launching station and receiving station can automated controlled.After the pig arrives at the receiver, it can return to the launcher automatically under the guidance of PLC program. The pig finally stays inside the launcher and it is cleaned together with the whole processing pipeline in CIP.

Manual product recovery system

Hyperfore manual pigging systems are hygienic. Many food processing pipelines only do the pigging process once er day, like some pet food plant, pigging frequency is not high, so cost is their main focus. Our manual pigging systems can satisfy their need, they are also designed without dead corners. The pig is manually inserted into the pipes, and is removed from the receiver manually. Before reinserting into the pipes, manual disinfection is required.

Aseptic pigging system

Hyperfore aseptic pigging systems are automated. They are used in food and pharmaceutical industries, which is very strict on hygiene. Aseptic pigging systems can undergo CIP and SIP.

Customized pigging solutions

Hyperfore pigging solutions include pigging process design, pigging automation PLC system, installation, on-site commissioning, technical support, operation training and so on. We will tailor the most suitable pigging solutions for our food, beverage and pharmaceutical customers based on their different production processes and situations

FAQ

Hello,

I’m Richard Gan, General Manager at Beijing Hyperfore Technology Company Ltd.

Since our founding in 2005, we have accumulated almost 10 years of focused experience in the Chinese market, specializing in the design and delivery of advanced sanitary pigging systems and integrated solutions.

If you have any questions, please feel free to contact us. We are pleased to provide you best products and services.

Email: wenbo.gan@hyperfore.cn WeChat: hyperfore2005

WhatsApp: +86 18910216756

Related Pigging Cases

If you are interested in cases about how pigging system benefit food industries, please refer to the articles.

If you have any questions about how much does a pigging system cost, or if you want to get a free quotation, please contact Hyperfore for more information.