What Affects Pig Movement in Pipes?

What Is a Pig Pipe?

What Affects Pig Movement in Pipes in sanitary pigging solutions?

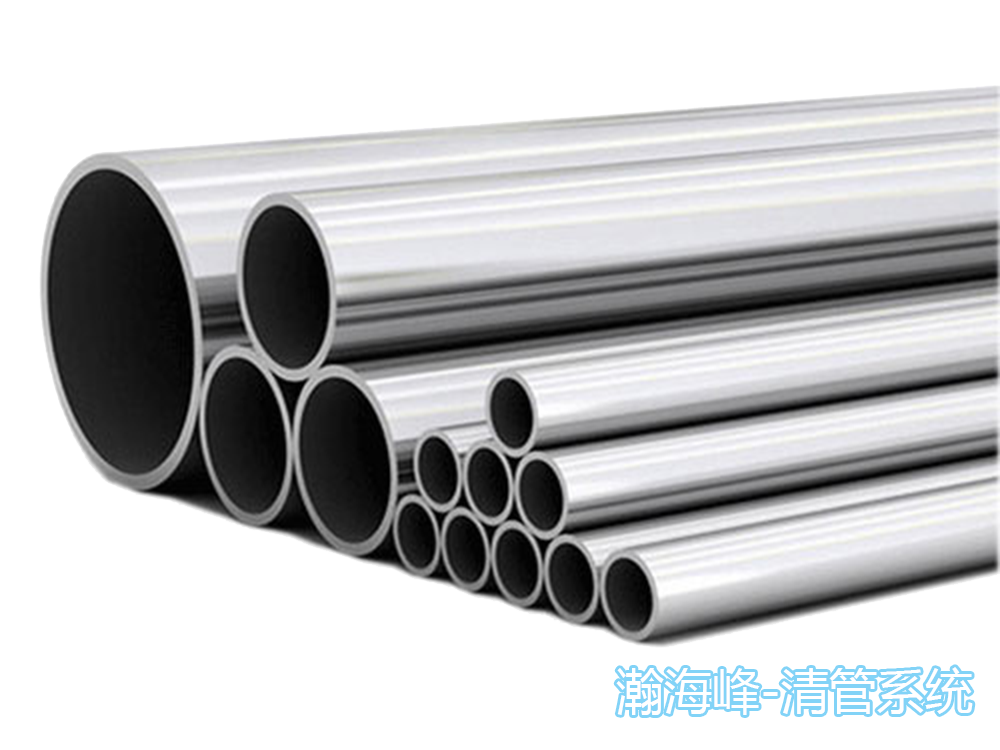

As the objects to be cleaned, pig pipes play the most important role in ensuring the quality of pigging in entire system, the quality of pig pipes determines the quality of pigging.” ”Before selecting a pipe size, the requirements for the entire pigging unit must be clarified. The requirements for hygiene can be low (coarse pigging system) or high (fine pigging system). For fine pigging systems, a pig pipe is a kind of Food Grade tubing. A sanitary pig pipe is Food approved. It is made of stainless steel 304 or 316L, offering the benefit of sanitation. For food, beverage and pharmaceutical industries, sterile environment is the requirement, hygienic tools and equipment are also very important.

《Industrial Pigging Technology》written by G. Hiltscher, W. Mühlthaler, .J Smits.

Factors Affecting Pig Movement in Pipes

Pigging Pipeline Material

Stainless steel is the most suitable material for pig pipes which transport batches of liquid products. So far, non-metallic pig pipes have only been used for rough cleaning. The standards for plastic pipes are the same as pressure pipes and sewer pipes.In some cases, glass pig pipes may be used in laboratories or demonstrations.

《Industrial Pigging Technology》written by G. Hiltscher, W. Mühlthaler, .J Smits.

Pickling and Passivating of Pig Pipes

Pickling and passivating can never be applied to pigging pipelines. Most manufacturers perform internal and external pickling by soaking. Some product recovery system suppliers think this can cause severe wear and tear on the pig. Careful pickling can prevent this from happening. However, pickling often results in a rough surface of the pigging pipeline.

Surface Roughness of Pig Pipes

Straight pipes with nominal sizes of 1” ~ 10” can be made into seamless pipes or straight seam pipes. Both types are suitable pigging pipelines.

The reason why welded pig pipes are better than seamless pipes are that they are suitable for larger diameter pipes and the production technology is more flexible.

Another advantage is that surface roughness of welded pig pipes can reach Ra=0.8μm for internal surface and Ra=1.6μm. for outer surface by manual polishing. Electropolishing can improve the surface quality of pig pipes, which is particularly important for pigging in the pharmaceutical fields.

《Industrial Pigging Technology》written by G. Hiltscher, W. Mühlthaler, .J Smits.

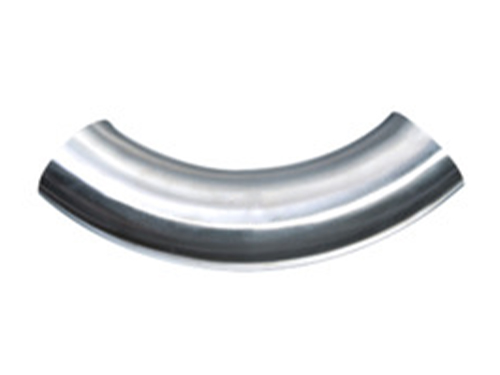

Curvature Radius of Elbows

In pigging pipelines, an appropriate elbow radius should be selected. The elbow radius is often a multiple of the nominal diameter.

Choosing elbow radius should consider:

- The higher the pigging effect, the larger the elbow radius.

- The higher the cleanness, the larger the elbow radius.

- The harder the pig material, the larger the elbow radius.

- The geometric size of the pipeline pig: the longer the pig, the larger the elbow radius.

Considering the above reasons, 5D elbows are highly recommended.

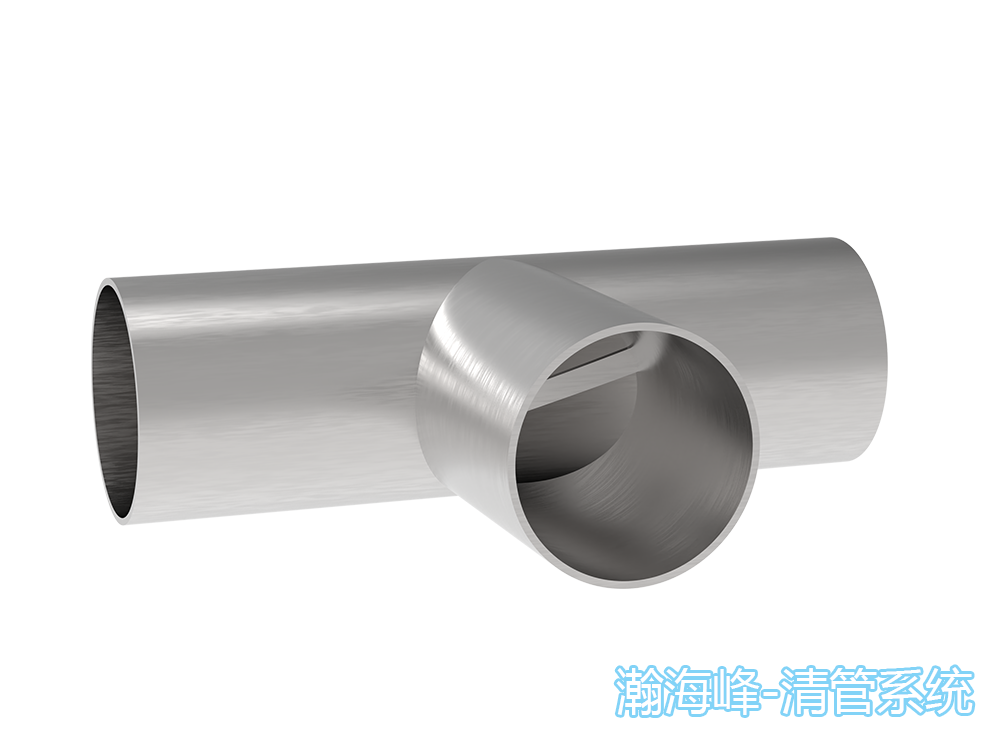

Quality of Tees

In order to ensure the pass through of the pig, the outlet diameter must be less than half of the nominal diameter of the pipeline, or a guide rod has to be welded at the outlet.

Get a Free Quote

Pipe Pig

Pipe Pig Design

Because the pigging application is similar for different fields, the design of the pig can’t be apparently different for specific application situations.

Pipe Pig Shape

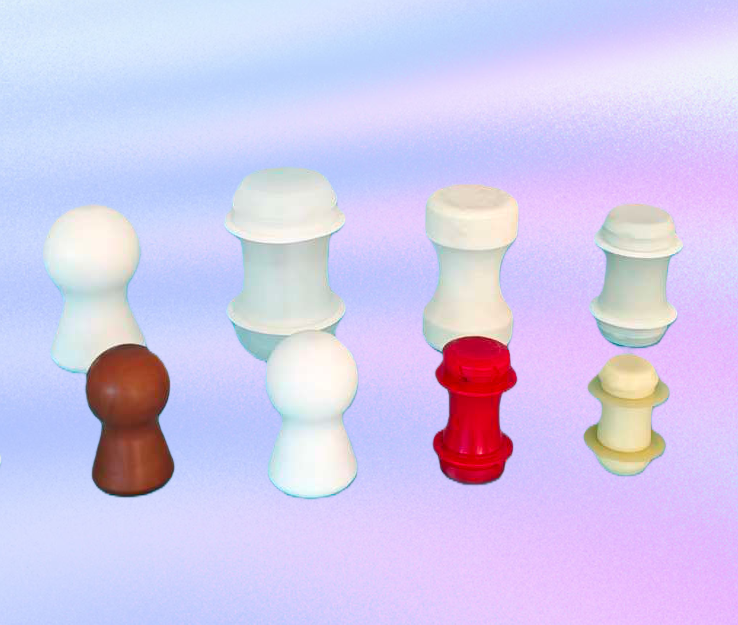

Pigs available are spherical pig, Integral casting pig, cup pig, cylindrical pig, pig with replaceable cup, conical sealing pig, and other specialized pigs. Choosing the right pig based on cleanness, pipe size and system pressure.

Spherical Pig

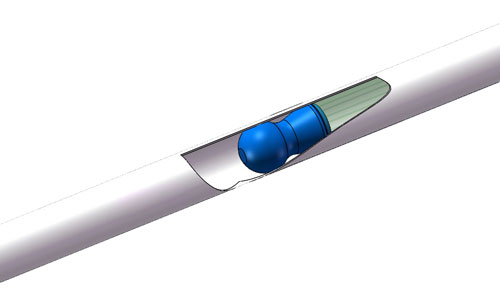

Of all types of pipeline pigs, spherical pig is the simplest in structure. It can rotate and move in any direction in the pigging pipeline. The direction of the spherical pig always changes.

Integral Casting Pig

Integral casting pig is very common pig. The pig is developed from spherical pig. Hyperfore integral casting pig can cater for most of the process requirements, it can move bidirectionally in the pipeline.

Replaceable Cup Pig

Specially designed pigging system is required to match the replaceable cup pig. Enough back pressure is required during operation, to control the pig speed.

《Industrial Pigging Technology》written by G. Hiltscher, W. Mühlthaler, .J Smits.

Sanitary (Aseptic) Pipeline Pig

Hyperfore sanitary (aseptic) pipeline pigs applied in sanitary fields use temperature resistant, wear resistant, product compatible materials. They are bi-directional pigs, the smooth surface and stable shape make it easy to be cleaned in place and pass through 3D elbows and tees without any difficulty.

Types of Driving Force:

The moving of pipe pigs is not driven by pigging system, it is driven by air or fluid propellant. Motion energy is transmitted from the driving medium to the pipe pig; therefore, the transmission properties are crucial to the motion. The motion situations of pigs are quite different driven by air or by fluid.

The air propellant can be compressed, which can lead to the unstable operation of the pig. Fluid propellant can offer ideal liquid flow behind the pig and make the pig move smoothly.

《Industrial Pigging Technology》written by G. Hiltscher, W. Mühlthaler, .J Smits.

Properties of Fluid Medium:

When paste like or high viscosity medium, as well as liquids with different fluid characteristics flowing through pipeline, pressure is generated on the inner wall of the pipe due to friction. These forces generate shear forces in the fluid due to the deformation of volume elements. The speed of the fluid near the pipe wall slows down due to friction. Therefore, the deformation is severe, yet the fluid in the center of the pipeline remains unchanged.

《Industrial Pigging Technology》written by G. Hiltscher, W. Mühlthaler, .J Smits.

Challenges and Considerations

The Construction of Pigging Pipelines

For pigging pipelines, components that can reduce the cross-sectional area of the pipes are forbidden, such as butterfly valves, filters, reducing tees. The inner diameter of the pig pipe should not change. Otherwise, the pig will not pass smoothly.

Generally speaking, pigging pipelines are connected by welding or flanges. For long distance pipes, welding is recommended for pig pipe connection. The number of flanges, valves, bends should be minimized as much as possible.

The Wearing of Pipe Pigs

The wearing character and service life of pipe pig depend on its resistance to product and cleaning agents of the material, also depend on specialized product performance (wear resistance, viscosity, stickiness, temperature), pipeline quality, inner surface of pipelines, welding seams and connecting components; the quality and curvature radius of pipeline elbows; the selection of pipe fittings and the reliability of the control system.

Pipe Pig Speed

The setting of the pipe pig speed is crucial. For pigs driven by air or Nitrogen, the ideal travelling speed is less than 2m/s, never more than 7m/s. When the driving propellant is liquid, The speed of the pipe pig is related to the power of the pump and the cross-sectional area of the pipeline, and the pipe pig speed is 2m/s.

《Industrial Pigging Technology》written by G. Hiltscher, W. Mühlthaler, .J Smits.

Conclusion

In summary the key factors influencing pig movement in pipes are Pigging Pipeline Material,Pickling and Passivating of pig pipes,Surface roughness of pig pipes,Curvature radius of elbows,Curvature radius of elbows,Quality of Tees,Pipe Pig Design,Pipe Pig shape,Types of Driving Force, Fluid Properties of Medium and so on. All the factors can have very important impact on the pig movement in pipelines, and further influences the performance of pigging process.

Pig movement in pipes are very important for optimizing pipeline pigging processes. When building pigging pipelines, Food Grade stainless steel (SS316L and SS304) should be the correct choice to minimize wear and tear of the pigs.

The number of fittings like elbows and tees, flanges should be kept to a minimum in order to avoid the potential failure of the pipe pig movement. In case fittings are needed, 3D elbows, piggable tees are ideals choice for pipe pig the pass smoothly.

The design of pipeline pigs plays an important role on pipeline cleaning effect. In order to achieve the best pipe cleaning effect, the size of the pipe pig should be slightly larger than the inner diameter of the pipe. The shape and material of the pipe pigs are key factors influencing the pipeline cleaning effect for different liquid products, like dairy, alcohol, cosmetics, food and so on.

Driving force can significantly affect the pipe pig speed, and further affect the lifespan of the pipe pig, as a result, it can have a deep effect on the pigging process efficiency.

FAQ

Related Articles

Related Cases

Hello,

I’m Richard Gan, General Manager at Beijing Hyperfore Technology Company Ltd.

Since our founding in 2005, we have accumulated almost 10 years of focused experience in the Chinese market, specializing in the design and delivery of advanced sanitary pigging systems and integrated solutions.

If you have any questions, please feel free to contact us. We are pleased to provide you best products and services.

Email: wenbo.gan@hyperfore.cn WeChat: hyperfore2005

WhatsApp: +86 18910216756