5 Types of Pipeline Pigs in Pigging System

Choosing the Right Hyperfore Pig: A Guide to Our 5 Sanitary Pipeline Pig Types

Hyperfore offers five distinct types of sanitary pipeline pigs, sometimes, it is a tough job for end users across different industries to determine which type of pigs can be used for a certain pigging application. However, this is Hyperfore’s field of expertise. Our efficient solutions extend beyong process design and engineering implementation, more importantly, we provide support for the selection of different types of pigs and selection of pigging products, and pigging technical support and services.

We’ve assisted so many customers globally to identify the best pipeline pigging equipment and they have gained a lot of benefits by cooperating with us in pigging, which will benefit their long-term development and success.

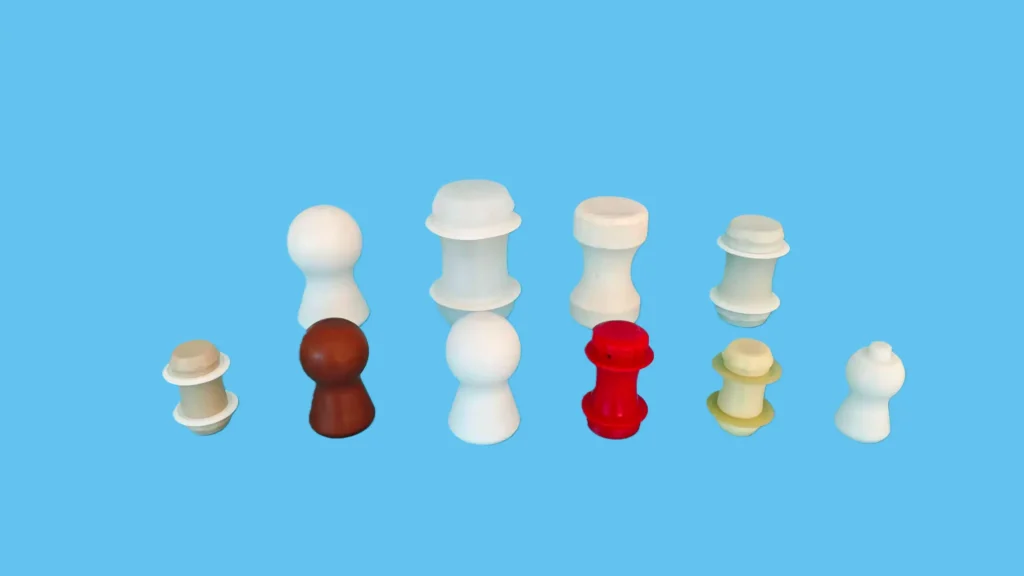

Replaceable lip pig

Lips of the pig are replaceable, components are easy to assemble and disassemble. The replaceable pig is bi-directional, providing flexible operation rather than being restricted to a single direction. The unique design make the lifespan of the replaceable lip pig very long, and economical.

It is suited for applications involving products with higher friction, as well as sanitary or aseptic liquid products with particles. The lips are robust and elastic. The lip pig is flexible, it is able to pass through 3D bends and 5D bends, piggable tees, hoses, it is also exhibits great tolerance when travelling along pipes with rough inner surfaces.

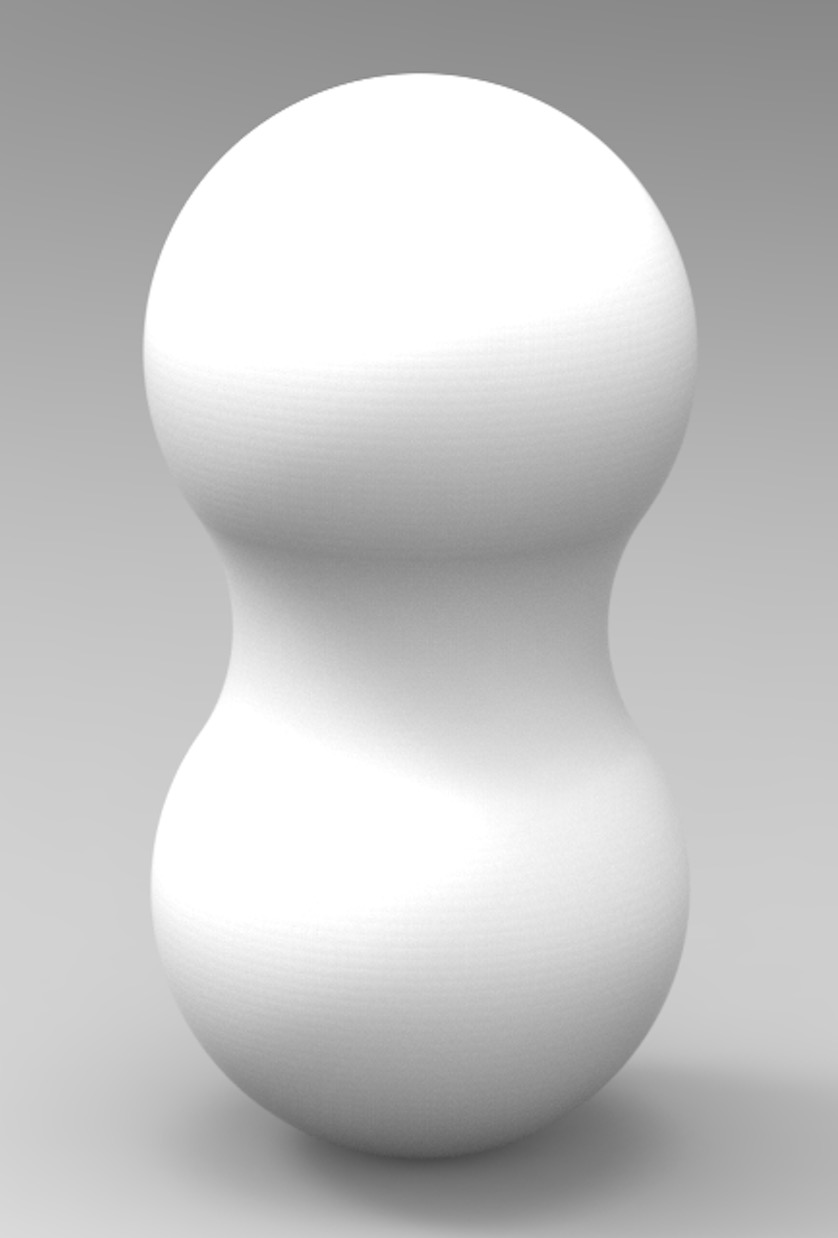

Tangent one-piece pig

Hyperfore one-piece pig is sanitary design. It is also bi-directional. The spherical head can evenly bear the force, easy to be inserted to the launcher. Thin waist make it possible to pass through 3D bends and 5D bends, meeting the requirements of complex engineering environment. Tangent one-piece pig is able to pass the reducing Tee easily. The permanent magnet is wrapped inside the pig. Even if an accident occurs, the permanent magnet will not produce debris pollution.

One function of sanitary one-piece pig is that the pig is used for almost all liquid processing pipelines, it can recover the residue product and make it available for sale. Another function is that, one-piece pig scrapes off the medium stuck to the inner wall of pipeline, protecting pipes from corrosion, and meanwhile minimizing the possibility of contamination between different batches of products.

Sanitary one-piece pig can be applied to almost all hygienic liquid processing pipeline. The industries include food, beverage, brewery, dairy, cosmetics, pharmaceuticals, chemicals, syrup, candy, chocolate and so on.

Get a Free Quote

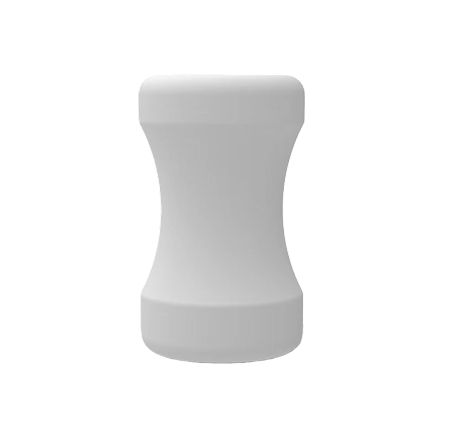

Double‐shoulder one-piece pig

Hyperfore double- shoulder pig is a kind of one-piece bi-directional, designed for pigging sterile area. It is constructed from materials that are product compatible, wear resistant, and temperature resistant(up to 121°C). Most importantly, the unique profile of the double-shoulder pig allows for safe and pore-free cleaning of all inner surfaces of the pipes,meeting the stringent demands of sterile environments.

The success of pigging technology depend on the selection of suitable pigs, and the performance and stability of the pigs are the most important. The double-shoulder pig satisfy all requirements for pigging process equipment, including impact-resistance, flexibility, strong magnetic field (easy to be detected by sensors). The double-shoulder design demands specific operational considerations. While it can fit tightly to pipe inner wall and result in high friction, it requires greater pushing pressure than Hyperfore replaceable lip-pig and tangent one-piece pig.

The double shoulder pig scrapes pipes very effectively and results in a higher product recovery rate and convenience in pipeline cleaning, it can be cleaned in the launcher as part of the system via CIP process. The materials can be PU, EPDM, VMQ,FKM and so on. Hyperfore Double-shoulder pig can be applied across many fields, including food, pharmaceuticals, chemicals, cosmetics, household cleaning agents, and more.

Double‐sphere one-piece pig

Hyperfore double‐sphere one-piece pig is specially designed for hygienic products, including food, beverage, pet food, daily chemicals. It is robust, durable, impact-resistant and heat-resistant(up to 121°C). The double‐sphere one-piece pig features a hygienic‐standard compliant, one‐piece molded structure, manufactured with highly wear‐resistant elastic materials. Its design characteristics include symmetrical spherical force‐bearing ends and a slim waist structure, enabling efficient back‐and‐forth movement within the pipeline, significantly enhancing pipeline cleaning and product recovery effects. It is suited for pigging sticky products and ensures a satisfying results for product recovery. The inside magnets and its strong magneti fields make the pig easy to be detected by Hyperfore pig detection unit anywhere along the pipeline.

Double‐sphere one-piece pig

Hyperfore powder recovering pig(Jet Pig)

Powder is widely used in pharmaceuticals, food, chemical, plastics, coatings, construction and other fields, it plays a very important role across diverse sectors. Powders serve various functions in food, medicine, filling materials, functional materials, pharmaceuticals and biological materials. Powder formulation is a common form in the modern pharmaceutical industry, and can be used to manufacture tablets, capsules, powders, oral liquids and other agents. In food industry, it can also exist in the form of milk powder, vegetable fat powder, starch, flour, etc.

To efficiently manage the challenges presented by these diverse powder applications, the Hyperfore Jet Pig is available. The jet pig is fully compatible with Hyperfore manual pigging system, automatic system for the above applications.

Jet Pig Features:

- There are six gas injection ports at the front end of the powder pig

- During the process of traveling in the pipeline, N2 can be ejected from the injection end to loosen the powder attached to the pipe wall, and the air flow is used to transport the floating powder to the destination to achieve a better pigging effect.

- Compatible with Hyperfore manual and automatic pigging system

- Improving powder yields, reducing powder waste, minimizing time and manpower required for further pipeline cleaning.

- Highly wear-resistant, food-grade pigging material

- ISO 1.5”-ISO 4” and DN40-DN150

- Materials EPDM/VMQ, other can be customized

How to locate the pigs in the pipes?

To monitor the location of pipeline pigs in real-time is crucial during pigging operations. The Pig detection unit, like other Hyperfore pigging products portfolio, is a key tool constructed to monitor and confirm the passage of the pig through certain key points along the pipe. Typically, our pig detection unit is clamped onto exterior pipe surface, primarily at the exit of the launching station and the entrance of the receiving station. Identifying the pig’s entrance into the pipeline from the launcher, or its arrival at the receiver is decisive for controlling the pigging process and ensuring operational safety.

Frequently Asked Questions

Hello,

I’m Richard Gan, General Manager at Beijing Hyperfore Technology Company Ltd.

Since our founding in 2005, we have accumulated almost 10 years of focused experience in the Chinese market, specializing in the design and delivery of advanced sanitary pigging systems and integrated solutions.

If you have any questions, please feel free to contact us. We are pleased to provide you best products and services.

Email: wenbo.gan@hyperfore.cn WeChat: hyperfore2005

WhatsApp: +86 18910216756