Pigging Application in Chocolate Manufacturing

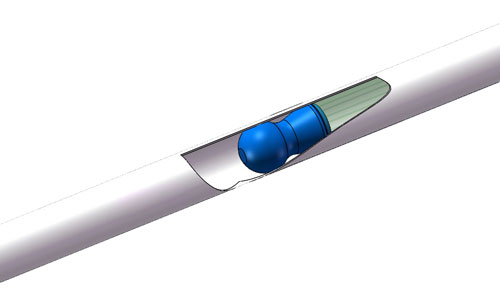

Chocolate is a delicious dessert beloved by many people. While the production process presents tough challenges, particularly in pipeline cleaning. Traditional pipe cleaning methods are inefficient, resulting in water waste and environmental pollution. Pigging system emerges as an ideal solution for chocolate pipe cleaning.

During complex chocolate manufacturing process, the task of cleaning chocolate pipeline could be a formidable task. Among all the considerations, food safety is definitely the priority, so the cleaning method should pass strict hygiene requirements. Meanwhile, the chocolate syrup is viscous, it is not easy to thoroughly clean the pipeline by water flushing. Chocolate pipeline needs insulation, insufficient temperature will cause product solidification and pipeline blockage. Manufacturers also face environment pressure to save water and reduce wastewater treatment costs.

Pigging Applications in Pipeline

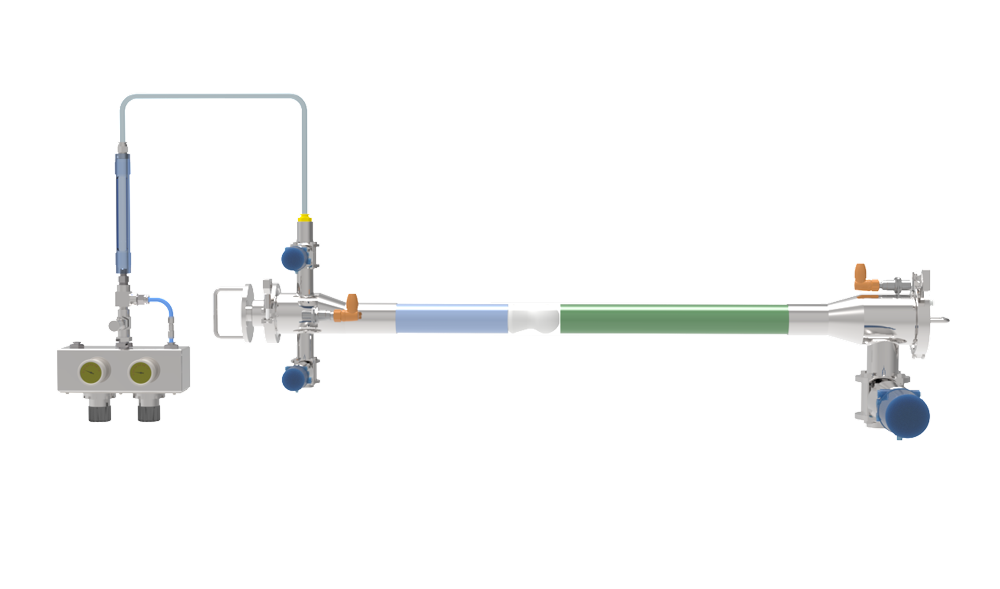

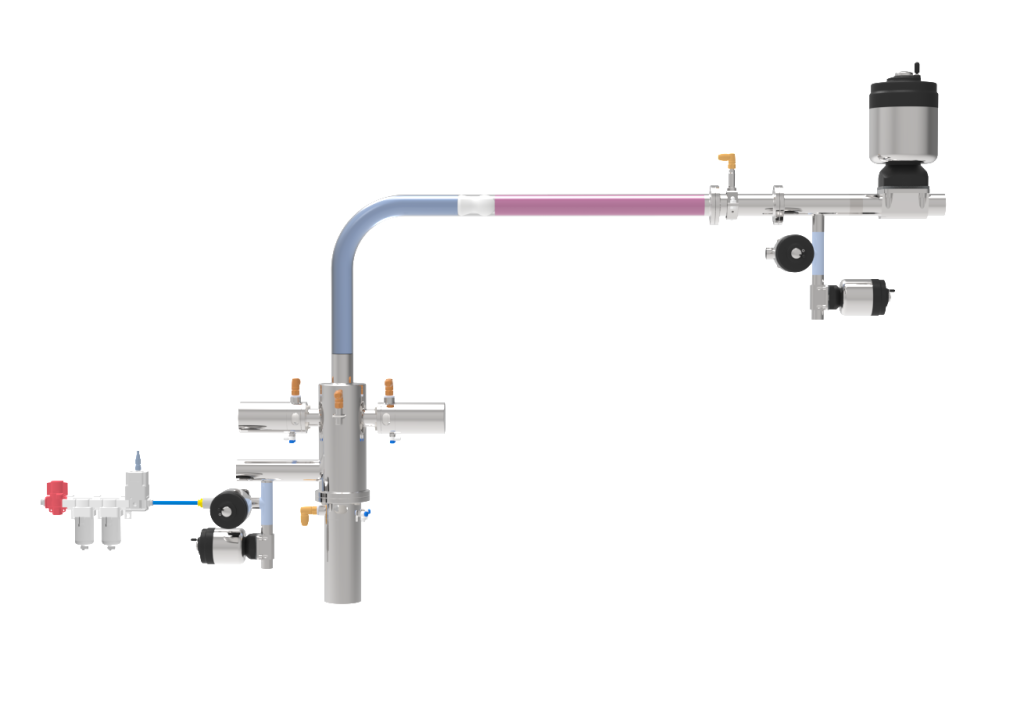

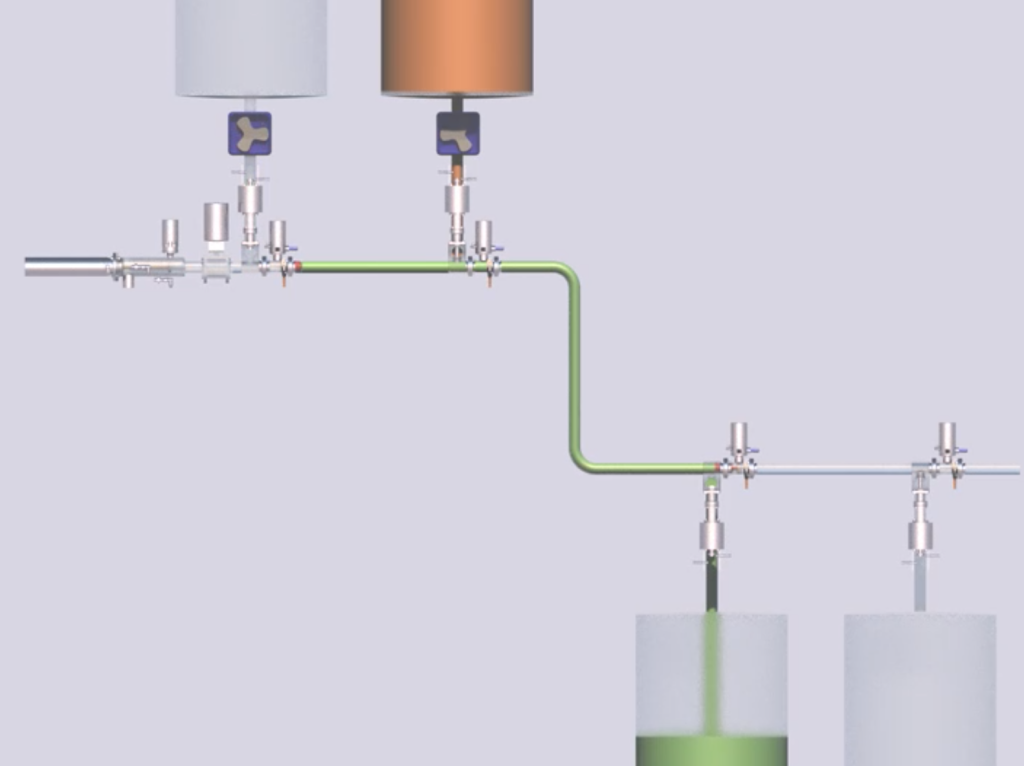

Hyperfore pigging system turnkey solutions can be implemented in a lot of applications. The following is detailed description of the chocolate pipeline pigging project.

| Client | Chocolate manufacturer |

|---|---|

| Product | Chocolate syrup |

| Pipe size | ISO 1.5inch |

| Process requirement | Pipe insulation |

| Pigging starting point | Two source syrup tank |

| Pigging ending point | Ice cream production line - chocolate coating area |

| Pipeline length | 80 meters |

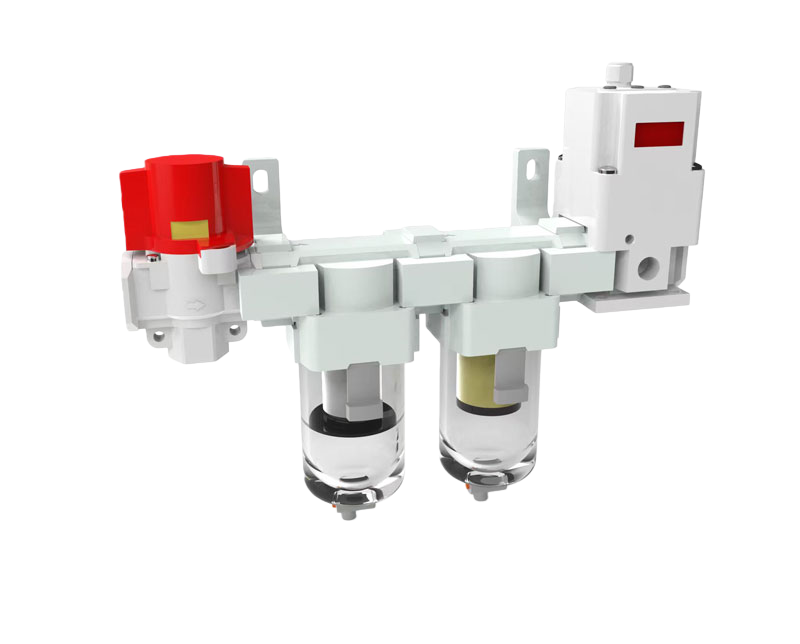

| Pigging system type | Automatic and sanitary |

Pigging Solutions and Implementation

| Specification | Value | Specification | Value |

|---|---|---|---|

| Unit price per liter | $2.52 | Product volume per meter of pipe | 3.42L |

| Recycling rate | 99% | Total product volume of 50-meter pipe | 171L |

| Pipe diameter | 38.1mm | Recycled product volume per day | 170L |

| Pipe length | 80 meters | Recycled product volume per month | 4250L |

| Pigging times per day | 1 | Amount saved per month | $10700 |

| Pigging times per month | 25 | Cost savings in sewage disposal per month | $52 |

| Total savings per month | $10752 |

Company Profile

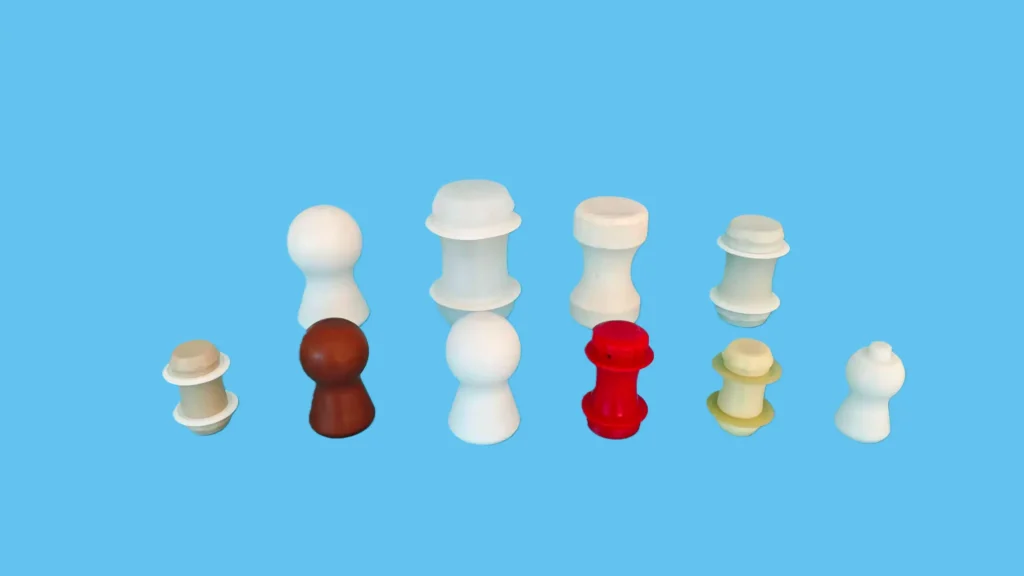

Hyperfore is a professional sanitary pigging systems and solutions supplier. We are sauce factory for sanitary pigging systems manufacturing. We boast rich experience of delivering high-quality turnkey pigging projects. Our dedicated engineering team can offer tailored pigging solutions including: pigging equipment and products, pigging process design, automation control, commissioning, installation and guidance, remote technical support, operating training.

Hyperfore has a proven track record of implementing successful pigging projects for both domestic and international clients, covering a wide range of industries. The pigging system applications include:dairy, drinks, alcoholics, household liquids, toothpaste, chemicals, pharmaceuticals, Chinese medicine, lithium battery slurry, paints and coatings, pigments and so on.

Our factory occupies an area of 2000 square meters, divided into four sections. The manufacturing workshop is equipped with advanced machineries, the assembling and testing workshop ensures high product quality, the warehouse is well organized to ensure optional storage and efficient logistics, and our office area is spacious and modern.

Our skilled team is mainly composed of experienced engineers, automation engineers, process engineers, installation engineers, mechanical engineers, purchasing engineers and so on. They have a proven track record in pigging system and liquid transfer engineering, and their extensive experience brings expertise to every project.

Our Advantages

Source

Factory

Customized

Solutions

Seamless

Integration

Modular

Design

Cost

Effective

High

Quality

Food

Approved

Robust

Reliable

Efficient

Logistics

Tailored

Service

Why Hyperfore Is the Best Choice

Certificates

As a professional sanitary pigging system and solutions supplier, we posses necessary certifications to meet different industry standard.